Table of Contents

- Can You Use Contact Plasma Cutter for CNC?

- Freequently Asked Questions

- Can a contact plasma cutter be used for CNC?

- What are the advantages of using a contact plasma cutter for CNC?

- What should I consider when using a contact plasma cutter for CNC?

- What are some tips for using a contact plasma cutter for CNC?

- What are some common problems when using a contact plasma cutter for CNC?

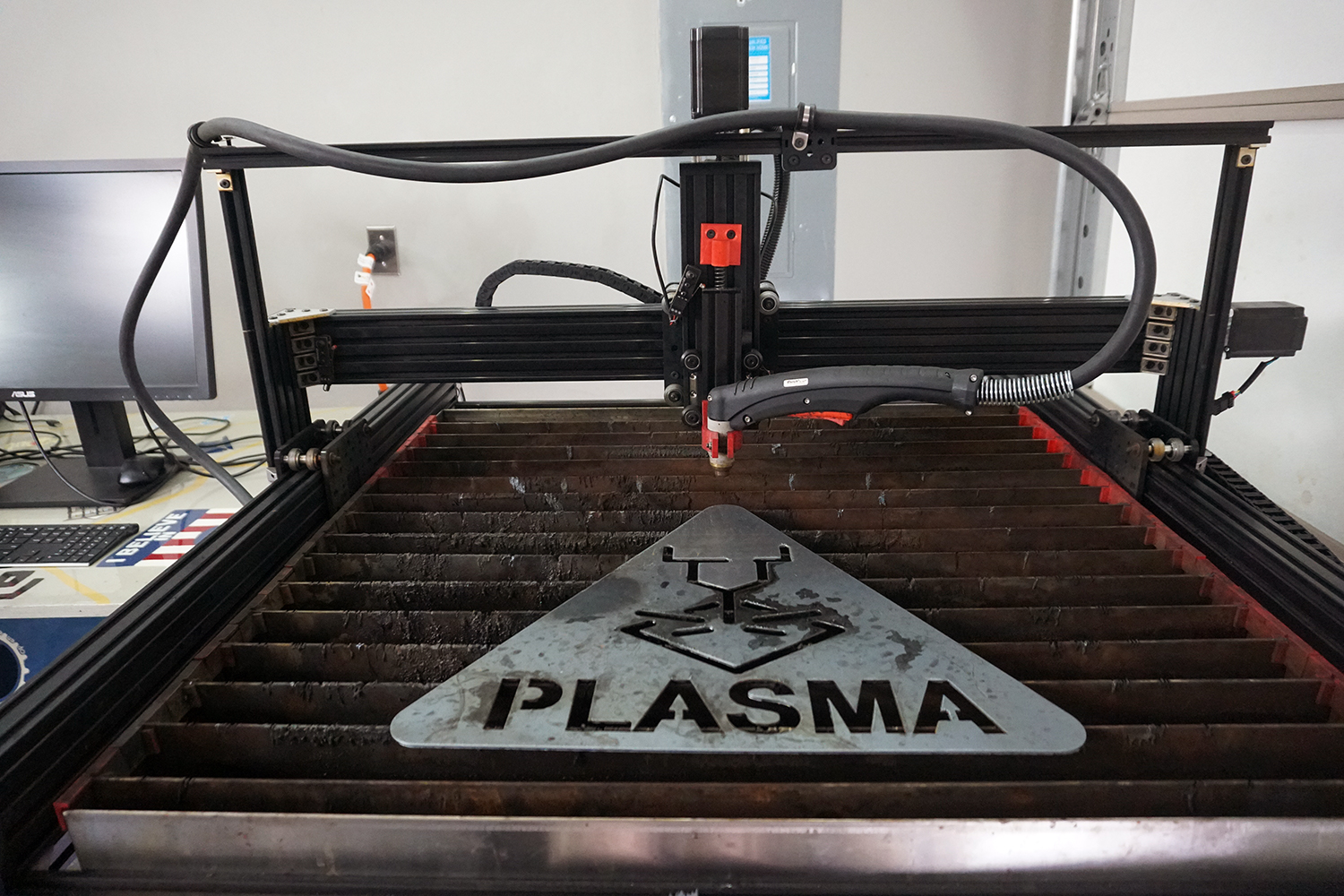

Are you looking for ways to enhance your CNC cutting experience? Have you ever wondered if you could use a contact plasma cutter for CNC? If so, you’ve come to the right place! In this article, we will explore the possibilities of using a contact plasma cutter for CNC and what benefits it can bring to your cutting endeavors.

Adding a contact plasma cutter to your CNC arsenal can significantly enhance your cutting capabilities. With its high-speed cutting and precision, a contact plasma cutter can produce clean cuts on various materials, including metals and non-metals. In the following paragraphs, we will dive deeper into the advantages and potential drawbacks of using a contact plasma cutter for CNC, so keep reading to learn more!

Can You Use Contact Plasma Cutter for CNC?

If you’re looking for a machine that can cut through metal with precision, you’re probably considering a CNC plasma cutter. However, you might be wondering whether you can use a contact plasma cutter for CNC. In this article, we’ll explore the answer to this question and the benefits and drawbacks of using a contact plasma cutter for CNC.

What Is a Contact Plasma Cutter?

A contact plasma cutter is a type of plasma cutter that comes into contact with the metal being cut. This type of cutter uses a high-frequency spark to ionize air into plasma, which then melts the metal. The plasma cutter torch has a nozzle that focuses the plasma into a narrow stream, enabling it to cut through metal with precision.

The biggest advantage of using a contact plasma cutter is that it’s inexpensive and easy to use. Unlike other types of plasma cutters, contact plasma cutters don’t require an external gas supply, making them more portable and convenient.

What Is a CNC Plasma Cutter?

A CNC plasma cutter is a machine that uses a computer-controlled system to cut through metal with precision. The CNC plasma cutter is equipped with a plasma torch that can be moved in three dimensions, allowing it to cut through metal in any direction. The computer controls the movement of the torch, ensuring that the cuts are precise and accurate.

The biggest advantage of using a CNC plasma cutter is that it’s highly accurate and efficient. The computer-controlled system ensures that the cuts are precise and consistent, reducing the risk of errors and waste.

Can You Use a Contact Plasma Cutter for CNC?

The short answer is yes, you can use a contact plasma cutter for CNC. However, there are some limitations to using a contact plasma cutter for CNC. Contact plasma cutters are not designed for high-volume cutting, and they may not be as accurate as other types of plasma cutters.

The biggest disadvantage of using a contact plasma cutter for CNC is that it may not be as precise as other types of plasma cutters. Contact plasma cutters rely on physical contact with the metal being cut, which can result in a less precise cut. Additionally, contact plasma cutters may not be capable of cutting through thick metal, which can limit their usefulness.

Benefits of Using a Contact Plasma Cutter for CNC

Despite the limitations of using a contact plasma cutter for CNC, there are some benefits to this approach. Contact plasma cutters are inexpensive and easy to use, making them a good option for small-scale cutting projects. Additionally, contact plasma cutters don’t require an external gas supply, making them more portable and convenient.

Another advantage of using a contact plasma cutter for CNC is that it can be used for cutting a variety of metals, including steel, aluminum, and copper. This versatility makes contact plasma cutters a good choice for a variety of applications, from hobby projects to small-scale manufacturing.

Drawbacks of Using a Contact Plasma Cutter for CNC

While there are some benefits to using a contact plasma cutter for CNC, there are also some drawbacks to consider. Contact plasma cutters may not be as accurate or precise as other types of plasma cutters, which can result in less precise cuts. Additionally, contact plasma cutters may not be capable of cutting through thick metal, which can limit their usefulness.

Another drawback of using a contact plasma cutter for CNC is that it may not be capable of cutting through certain types of metal. For example, contact plasma cutters may not be capable of cutting through stainless steel, which can limit their usefulness in certain applications.

Conclusion

In conclusion, while you can use a contact plasma cutter for CNC, there are some limitations to consider. Contact plasma cutters are not designed for high-volume cutting and may not be as accurate or precise as other types of plasma cutters. However, there are some benefits to using a contact plasma cutter for CNC, including their low cost and versatility. Ultimately, the choice of plasma cutter for CNC will depend on your specific needs and budget.

Freequently Asked Questions

Here are some common questions about using a contact plasma cutter for CNC:

Can a contact plasma cutter be used for CNC?

Yes, a contact plasma cutter can be used for CNC. In fact, many CNC machines are designed to work with plasma cutters. However, it’s important to make sure that your plasma cutter is compatible with your CNC machine before using it. You should also make sure that your plasma cutter is properly calibrated and that you have the correct settings for your cutting job.

Using a contact plasma cutter for CNC can offer many benefits, including faster cutting speeds, cleaner cuts, and less material waste. However, it’s important to have the right equipment and knowledge to use it safely and effectively.

What are the advantages of using a contact plasma cutter for CNC?

There are many advantages to using a contact plasma cutter for CNC. One of the biggest advantages is faster cutting speeds. Plasma cutters are able to cut through thick metal quickly, which can save time and increase productivity. Another advantage is cleaner cuts. Plasma cutters produce a narrow kerf, which means less material is wasted and edges are cleaner. Finally, plasma cutters are versatile and can cut through a variety of materials, including steel, aluminum, and copper.

However, there are some disadvantages to using a contact plasma cutter for CNC as well. Plasma cutters can be expensive and require regular maintenance. They can also produce a lot of noise and heat, which can be dangerous if not properly controlled.

What should I consider when using a contact plasma cutter for CNC?

When using a contact plasma cutter for CNC, there are several things to consider. First, you should make sure that your plasma cutter is compatible with your CNC machine. You should also make sure that your plasma cutter is properly calibrated and that you have the correct settings for your cutting job. Additionally, you should wear proper safety gear, such as gloves and eye protection, and make sure that your work area is well-ventilated.

You should also be aware of the noise and heat generated by the plasma cutter and take steps to control it. Finally, you should be aware of the cost of using a contact plasma cutter for CNC, including the cost of the equipment, maintenance, and consumables such as electrodes and nozzles.

What are some tips for using a contact plasma cutter for CNC?

Here are some tips for using a contact plasma cutter for CNC:

- Make sure that your plasma cutter is properly calibrated and that you have the correct settings for your cutting job.

- Wear proper safety gear, such as gloves and eye protection, and make sure that your work area is well-ventilated.

- Control the noise and heat generated by the plasma cutter by using a soundproof enclosure or ventilation system.

- Use the correct consumables, such as electrodes and nozzles, to ensure optimal performance.

- Regularly maintain your plasma cutter to ensure that it is in good working condition.

What are some common problems when using a contact plasma cutter for CNC?

Some common problems when using a contact plasma cutter for CNC include poor cut quality, excessive noise and heat, and consumable wear. Poor cut quality can be caused by incorrect settings or worn consumables, while excessive noise and heat can be caused by inadequate ventilation or a poorly-designed soundproof enclosure. Consumable wear is a natural part of using a plasma cutter and can be minimized by using high-quality consumables and regularly maintaining your equipment.

If you are experiencing problems when using a contact plasma cutter for CNC, it’s important to troubleshoot the issue and make any necessary adjustments to your equipment or settings. You may also want to consult with a professional or the manufacturer of your equipment for additional guidance.

In conclusion, using a contact plasma cutter for CNC is possible, but it requires some additional steps and equipment. While a contact plasma cutter can provide high-quality cuts with minimal heat input, it lacks the precision and repeatability of a dedicated CNC plasma cutter.

If you are on a tight budget or have limited space, a contact plasma cutter may be a viable option for your CNC needs. However, if precision and accuracy are critical to your project, investing in a dedicated CNC plasma cutter is the way to go.

Ultimately, the decision to use a contact plasma cutter for CNC will depend on your specific needs and budget. It’s essential to weigh the pros and cons carefully before making a final decision. With the right tools and techniques, a contact plasma cutter can deliver excellent results for your CNC projects.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com