Table of Contents

Are you tired of manually inputting CNC G code into your machine? Are you looking for a more efficient way to turn your SVG files into G code? Look no further! In this article, we will guide you through the step-by-step process of turning your SVG files into CNC G code, saving you time and effort in the long run.

With our easy-to-follow instructions and tips, you will learn how to use various software programs to convert your SVG files into G code, as well as how to customize your code to fit your specific machine’s requirements. Whether you’re a beginner or an experienced CNC operator, this guide will provide you with the knowledge and tools you need to streamline your CNC workflow and produce high-quality results.

- Open a CAD software that can export SVG files.

- Import your SVG file into the CAD software.

- Use the CAD software to create tool paths and generate G-code.

- Save the G-code file onto a USB drive.

- Insert the USB drive into your CNC machine.

- Run the G-code file on your CNC machine to create the desired object.

How to Turn a SVG into CNC G Code?

If you are interested in CNC machining, you must have heard about the term G code. G code is a programming language that is used to control CNC machines. CNC machines are automated machines that use computer-controlled software to create precise and complex designs. If you have a design in SVG format and want to use it in CNC machining, you need to convert the SVG into G code. In this article, we will discuss how to turn an SVG into CNC G code.

Understanding SVG and G Code

SVG stands for Scalable Vector Graphics. It is a vector image format that is used for graphics and icons on the web. SVG files are created using vector graphics software like Adobe Illustrator or Inkscape. On the other hand, G code is a language that is used to control CNC machines. G code commands are sent to the CNC machine to tell it what movements to make and at what speed.

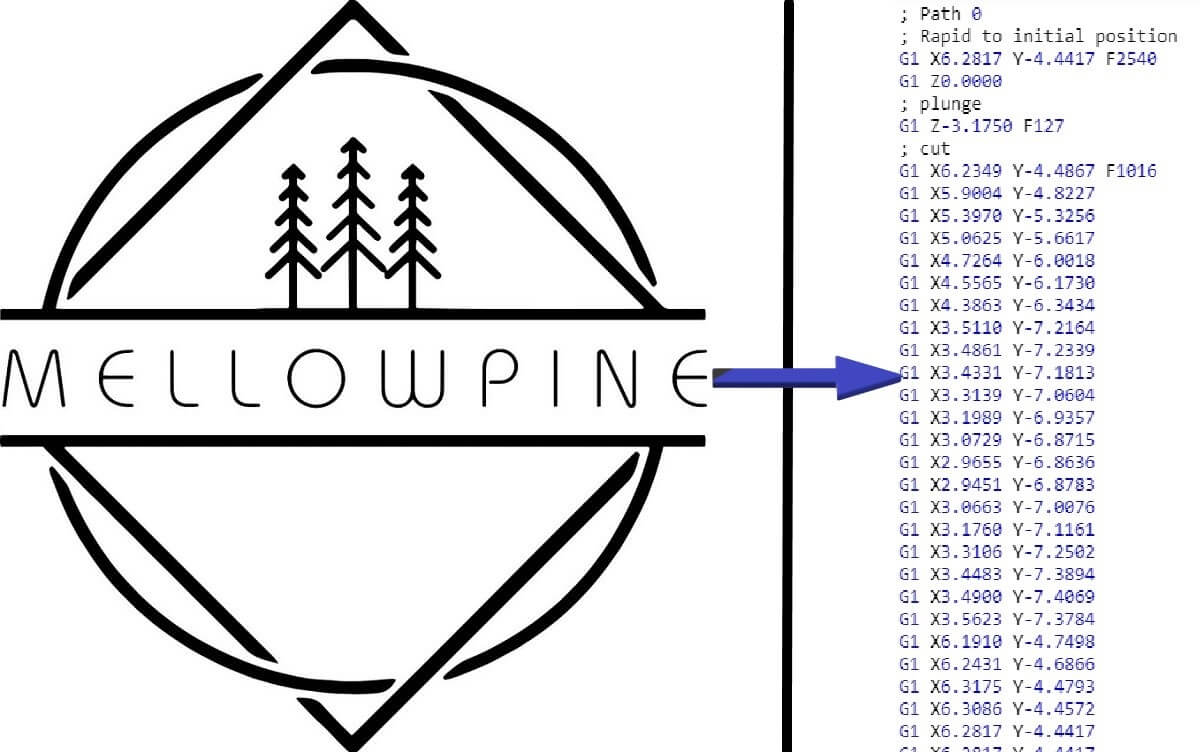

To convert an SVG file into G code, you need to use a CAM software. CAM stands for Computer-Aided Manufacturing. CAM software takes a design file and generates G code that the CNC machine can read. There are many CAM software available in the market, such as Fusion 360, Vectric VCarve, and CAMWorks.

Converting SVG to G Code

To convert an SVG file into G code, you need to follow these steps:

1. Open your CAM software and import the SVG file you want to convert.

2. Set up the parameters for your CNC machine, such as the size of the material and the cutting tool you will use.

3. Set up the machining strategy, such as the cutting depth, the speed, and the toolpath.

4. Generate the G code by clicking on the post-processor button.

5. Save the G code file to your computer.

Once you have the G code file, you can load it into your CNC machine and start the machining process.

Benefits of Using SVG and G Code

SVG and G code are powerful tools that can help you create complex designs with precision and accuracy. By using a vector format like SVG, you can scale your design to any size without losing quality. G code allows you to control the movements of the CNC machine with precision, resulting in accurate cuts and carvings.

Another benefit of using SVG and G code is the ability to automate the machining process. Once you have the G code file, you can use it to create multiple copies of the same design without having to go through the design process again.

SVG vs. G Code

SVG and G code are two different formats used for different purposes. SVG is a vector format used for graphics and icons on the web, while G code is a programming language used to control CNC machines.

SVG files can be created using vector graphics software like Adobe Illustrator or Inkscape, while G code is generated using CAM software. SVG files are static images, while G code is a set of commands that tell the CNC machine what movements to make.

In conclusion, turning an SVG file into G code is a simple process that requires a CAM software. By using SVG and G code, you can create complex designs with precision and accuracy, automate the machining process, and achieve accurate cuts and carvings.

Frequently Asked Questions

Here are some common questions about turning an SVG file into CNC G code.

What is an SVG file?

SVG stands for Scalable Vector Graphics. It is a type of file format used for images that can be scaled up or down without losing quality. These files are often used in web design, but they can also be used in CNC machines.

SVG files are made up of lines, curves, and other shapes that can be easily converted into G code, which tells a CNC machine how to move and cut the material.

How do I convert an SVG file into CNC G code?

To convert an SVG file into CNC G code, you will need to use a software program that can do the conversion. There are several options available, including software that is specifically designed for CNC machines.

One popular option is CAM software, which stands for Computer-Aided Manufacturing. This software takes the 2D or 3D design from the CAD software and creates a toolpath that the CNC machine can follow to make the cuts.

What are the benefits of using SVG files for CNC machining?

One of the main benefits of using SVG files for CNC machining is that they are scalable. This means that you can use the same file for different sizes of material without having to create a new design.

SVG files are also easy to edit and modify. If you need to make changes to the design, you can do so quickly and easily in a vector graphics editor like Adobe Illustrator or Inkscape.

What are some common mistakes to avoid when converting an SVG file into CNC G code?

One common mistake is not properly setting up the toolpath in the CAM software. This can lead to the CNC machine making incorrect cuts or not cutting deeply enough.

Another mistake is not properly calibrating the machine before starting the job. This can result in inaccurate cuts and wasted material.

What materials can be used with CNC machines?

CNC machines can be used with a variety of materials, including wood, plastic, metal, and composites. The specific materials that can be used will depend on the type of machine and the cutting tools being used.

It is important to choose the right material for your project and to ensure that the CNC machine is set up correctly to work with that material.

In conclusion, turning an SVG file into CNC G-code can be a daunting task for beginners. However, with the right tools and knowledge, it can be a simple and rewarding process.

Firstly, it’s important to ensure that the SVG file is properly formatted and compatible with your CNC machine. This can be achieved by using software such as Inkscape or Adobe Illustrator to clean up the file and make any necessary adjustments.

Secondly, you will need to use a CAM software to generate the G-code that your CNC machine can understand. Popular options include Fusion 360, Vectric, and Carbide Create.

Finally, it’s important to test your G-code on a small scale before running it on your actual project. This will help you identify any errors or issues and ensure that your final product is of the highest quality.

Overall, turning an SVG file into CNC G-code requires patience, attention to detail, and a willingness to learn. With these tips and tools, you can successfully bring your designs to life with CNC machining.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com