Table of Contents

If you’re new to CNC lathe machining or looking to improve your skills, you’ll need to know how to write G code. G code is the language used to control and automate CNC machines, and it’s essential for creating accurate and precise parts. But where do you begin? In this article, we’ll cover the basics of G code writing for CNC lathe machines and provide some tips for optimizing your programs.

From understanding the different types of G code commands to using software to generate code, we’ll break down the steps you need to take to write effective G code. Whether you’re a beginner or an experienced CNC machinist, mastering G code is a critical step in becoming a skilled and efficient operator. So let’s dive into the world of CNC lathe programming and learn how to write G code like a pro.

How to Write G Code for CNC Lathe?

- Start by understanding the basics of G code language and the specific format used for CNC lathes.

- Choose a text editor or software program that allows you to create and edit G code.

- Identify the specific commands needed for your project, such as cutting speed, tool selection, and axis movements.

- Use the appropriate codes and syntax to create your G code program.

- Test your program on a simulator or with scrap material before running it on the CNC lathe.

How to Write G Code for CNC Lathe?

If you are a CNC lathe operator or programmer, you know how important it is to have accurate and efficient G code programs. G code is the language that controls the movements of the CNC lathe machine, and learning how to write it is essential to maximizing the machine’s capabilities. In this article, we will discuss the steps you need to take to write G code for a CNC lathe machine.

Understanding G Code Basics

G code is a language that is used to control CNC machines. It is a set of instructions that tells the machine what movements to make, at what speed, and in what direction. G code is made up of a series of commands that are executed one after the other to create the desired motion.

One of the most important things to understand about G code is that it is a numerical language. Each command is represented by a number, and the machine reads these numbers to determine what to do. For example, the command G01 tells the machine to move in a straight line at a specific speed, while G02 and G03 tell the machine to move in a circular motion.

To write G code for a CNC lathe machine, you need to have a good understanding of the basic commands and their functions. You also need to know how to read engineering drawings and interpret them into G code instructions.

Preparing the Engineering Drawing

Before you start writing G code, you need to have an engineering drawing of the part you want to create. The drawing should include all the dimensions and specifications of the part, including the material, the tolerances, and the surface finish requirements.

Once you have the drawing, you need to analyze it and determine the best approach to machine the part. This involves deciding which tools to use, the sequence of operations, and the cutting parameters.

Writing the G Code

Once you have analyzed the engineering drawing and determined the machining process, you can start writing the G code. The first step is to set up the machine parameters, such as the spindle speed, feed rate, and tool offsets.

Next, you need to write the G code commands for each operation. This involves selecting the appropriate G code command for each movement, as well as the speed and direction of the movement. You also need to include commands for tool changes, coolant on/off, and other machine functions.

Simulating the G Code

Before you run the G code on the CNC lathe machine, it is a good idea to simulate it using software. This allows you to check for errors, collisions, and other issues that may arise during the machining process.

There are many software programs available that can simulate G code for CNC machines. These programs allow you to view the part being machined in 3D, as well as check for any problems that may occur during the process.

Running the G Code on the CNC Lathe Machine

Once you have written and simulated the G code, you can run it on the CNC lathe machine. Before you start, make sure that the machine is properly set up and that all safety precautions have been taken.

To run the G code, you need to load it into the machine’s controller. This can be done using a USB drive, network connection, or other methods. Once the G code is loaded, you can start the machining process and monitor it using the machine’s control panel.

Benefits of Writing G Code for CNC Lathe

Writing G code for a CNC lathe machine has many benefits. It allows you to create customized parts that meet specific design requirements, and it also increases efficiency by automating the machining process. In addition, writing G code gives you more control over the machining process, allowing you to optimize tool paths and cutting parameters for better results.

G Code vs. CAM Software

While G code is a powerful tool for controlling CNC machines, it is not the only option. CAM software is another popular option that allows you to create G code programs without having to write them manually.

CAM software uses a graphical interface to create tool paths and generates G code automatically. This can save time and reduce errors, especially for complex parts. However, CAM software can be expensive and may require additional training.

Conclusion

Writing G code for a CNC lathe machine is an essential skill for any operator or programmer. By understanding the basics of G code and following the steps outlined in this article, you can create accurate and efficient programs that maximize the machine’s capabilities. Whether you choose to write G code manually or use CAM software, the key is to understand the machining process and have a good understanding of the engineering drawing.

Frequently Asked Questions

Here are some frequently asked questions about writing G code for CNC Lathe.

What is G Code and How is it Used in CNC Lathe?

G code is a programming language that is used to control CNC machines. It consists of a series of commands that are used to control the movement of the machine, as well as other functions such as tool changes and coolant control. In CNC Lathe, G code is used to control the movement of the cutting tool along the axis of the workpiece, as well as to specify the toolpath and other parameters.

Writing G code for CNC Lathe can be a complex task, as it requires knowledge of the machine’s capabilities and limitations, as well as an understanding of the cutting process and the materials being used. However, with practice and experience, it is possible to become proficient in writing G code for CNC Lathe.

What Software is Used to Write G Code for CNC Lathe?

There are many software programs available for writing G code for CNC Lathe. Some popular options include Mastercam, GibbsCAM, and BobCAD-CAM. These programs allow users to create toolpaths and other parameters, as well as to simulate the cutting process before running the program on the machine.

When choosing a software program for writing G code for CNC Lathe, it is important to consider factors such as ease of use, compatibility with the machine, and support for the specific features and functions required for the job.

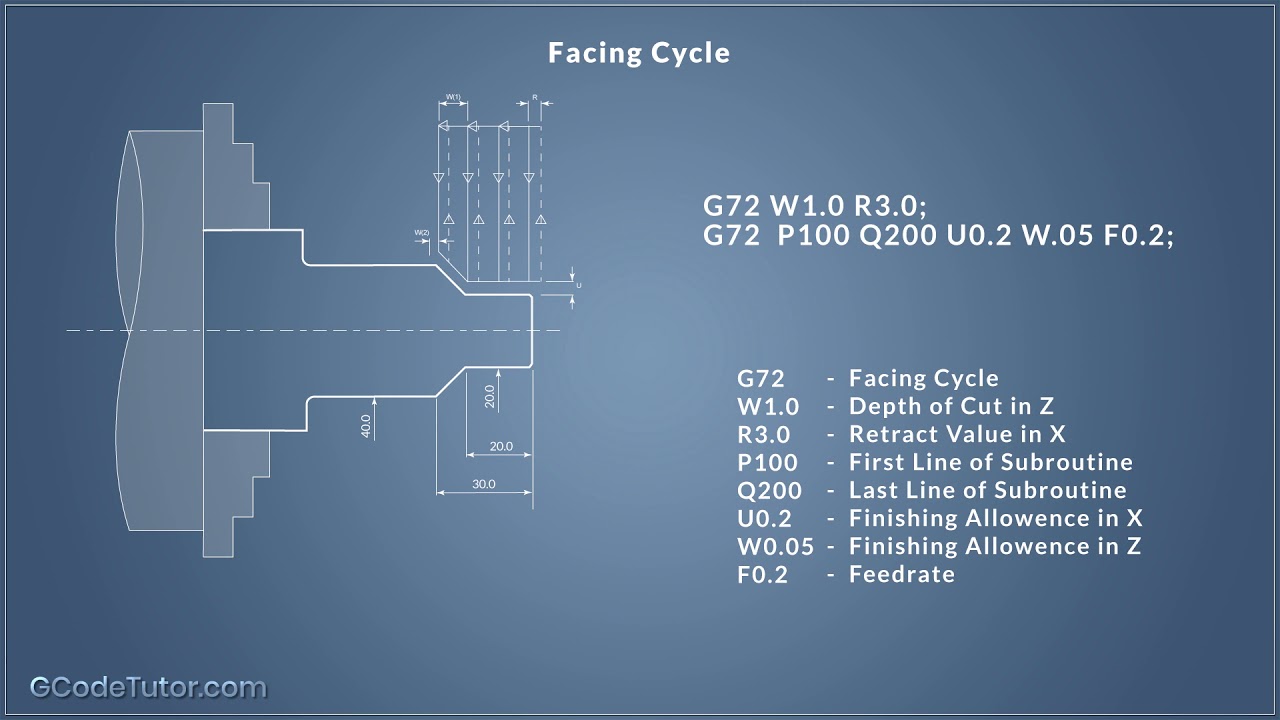

What are the Common Commands Used in G Code for CNC Lathe?

There are many commands used in G code for CNC Lathe, but some of the most common include G00 (rapid positioning), G01 (linear interpolation), G02/G03 (circular interpolation), G04 (dwell), G20/G21 (inch/metric units), G28/G29 (machine home), M03/M04/M05 (spindle control), M06 (tool change), and M08/M09 (coolant control).

Depending on the specific machine and cutting process being used, there may be additional commands required. It is important to consult the machine manual and other resources to ensure that the correct commands are used for the job.

What are Some Tips for Writing G Code for CNC Lathe?

When writing G code for CNC Lathe, it is important to start with a clear understanding of the cutting process and the materials being used. This includes factors such as the required tolerances, the cutting speed and feed rate, and the depth of cut.

It is also important to carefully plan the toolpath and to optimize it for efficiency and accuracy. This may involve using different tools for different operations, as well as making use of features such as tool compensation and spindle synchronization. Finally, it is important to test the program on a scrap piece of material before running it on the actual workpiece, in order to ensure that the program is correct and that the machine is set up correctly.

What are Some Common Mistakes to Avoid When Writing G Code for CNC Lathe?

One common mistake when writing G code for CNC Lathe is to use incorrect commands or parameters, which can result in damage to the machine or the workpiece. Another mistake is to use incorrect toolpaths or to fail to optimize the program for efficiency and accuracy.

It is also important to avoid errors such as forgetting to set the correct units or failing to properly program the tool changes and coolant control. Finally, it is important to carefully check the program for errors and to test it on a scrap piece of material before running it on the actual workpiece.

In conclusion, writing G code for CNC lathe can seem like a daunting task, but it is a skill that can be learned with practice and patience. By following the steps mentioned above, you can create efficient and effective G code programs that can produce precise and accurate parts on your CNC lathe.

It’s essential to keep in mind that G code programming requires attention to detail and a deep understanding of the machine’s capabilities. It’s recommended to test your programs thoroughly before running them on your CNC lathe to avoid any errors or issues.

Lastly, always stay up-to-date with the latest advancements in CNC technology and programming techniques. This way, you can continue to improve your skills and stay ahead in the ever-growing CNC industry.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com