Table of Contents

- Frequently Asked Questions

- What is a CNC drilling machine?

- What are the components of a CNC drilling machine?

- What materials can be drilled with a CNC drilling machine?

- How accurate is a CNC drilling machine?

- What are the advantages of using a CNC drilling machine?

- Tool Cutting manufacturing Drilling and Tapping CNC Machine. Tools Deep Drilling machining

Have you ever wondered how complex shapes and precision holes are made in metal or other hard materials? The answer is CNC drilling machines. These machines have revolutionized the manufacturing industry by allowing for more accurate and efficient drilling processes. In this article, we will take a closer look at the working principles of CNC drilling machines and how they have changed the manufacturing industry. So, let’s dive in and explore how these machines work!

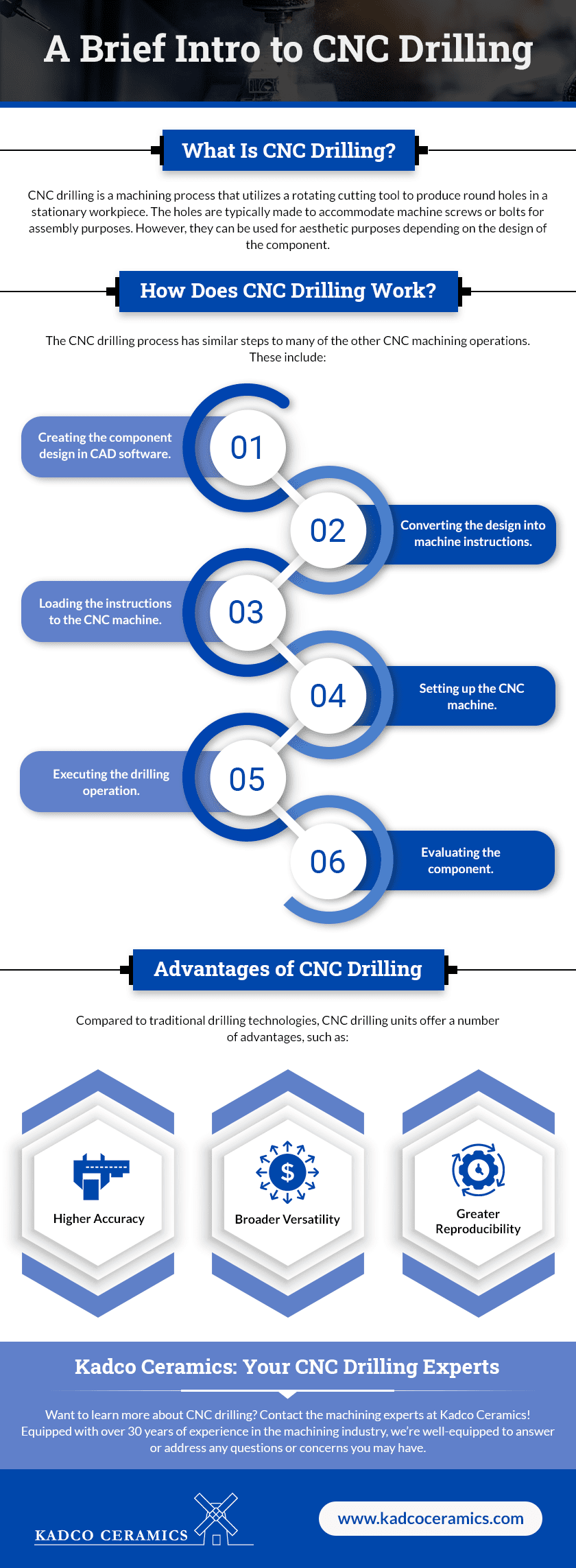

A CNC drilling machine operates by utilizing a computer program to control its movements. The machine is equipped with drill bits that are capable of drilling precise and accurate holes in a variety of materials. The program tells the machine where to drill, how deep to drill, and at what speed to drill. The machine then moves the drill bit to the desired location and starts drilling. CNC drilling machines are commonly used in manufacturing processes, where accuracy and precision are critical.

How CNC Drilling Machine Works?

CNC drilling machines are a type of computer-controlled machine tool that is used to precisely drill holes in various materials such as metal, plastic, and wood. These machines are highly versatile and can be used for a wide range of applications, from creating precise holes for electronic components to drilling holes for bolts and screws. In this article, we will take a closer look at how CNC drilling machines work.

1. CNC Drilling Machine Basics

CNC drilling machines use a computer-controlled drill bit to create holes in a workpiece. The machine tool is programmed to move the drill bit in a precise pattern to create the desired hole size and shape. The drill bit is typically made of high-speed steel or carbide and can be changed out to accommodate different hole sizes and materials.

One of the key features of a CNC drilling machine is its ability to precisely control the depth and diameter of the hole. This is achieved by using sensors and software to monitor the drilling process and make adjustments in real-time. The result is a highly accurate and repeatable drilling process that can be used for mass production.

2. Types of CNC Drilling Machines

There are several types of CNC drilling machines, including vertical, horizontal, and multi-axis machines. Vertical drilling machines are typically used for drilling holes in flat surfaces, while horizontal drilling machines are used for drilling holes in cylindrical or spherical surfaces.

Multi-axis drilling machines can move the drill bit in multiple directions, allowing for more complex hole shapes and patterns. These machines are often used for drilling holes in advanced aerospace components, where precision and accuracy are critical.

3. Benefits of CNC Drilling Machines

CNC drilling machines offer several benefits over traditional drilling methods. One of the main advantages is their ability to produce highly accurate and repeatable holes. This is especially important for industries such as aerospace and electronics, where precision is critical.

Another benefit of CNC drilling machines is their ability to automate the drilling process, which can save time and reduce labor costs. Additionally, these machines can be programmed to drill holes in a variety of materials, including metals, plastics, and composites.

4. Vs Traditional Drilling Methods

Compared to traditional drilling methods, CNC drilling machines offer several advantages. Traditional drilling methods typically require a skilled operator to manually drill each hole, which can be time-consuming and prone to errors. CNC drilling machines, on the other hand, can be programmed to drill multiple holes simultaneously, which saves time and reduces the risk of errors.

In addition, CNC drilling machines can drill holes in a wider range of materials than traditional drilling methods. This is because they use specialized drill bits that are designed to handle different materials, such as carbide-tipped bits for drilling hard metals.

5. Applications of CNC Drilling Machines

CNC drilling machines are used in a wide range of industries, including aerospace, automotive, electronics, and construction. They are often used for drilling holes in complex components such as engine blocks, circuit boards, and aircraft parts.

In the aerospace industry, CNC drilling machines are used to create precision holes in aircraft components such as wings, fuselages, and engine parts. These holes must be drilled to exact specifications to ensure that the aircraft is safe and reliable.

6. Maintenance of CNC Drilling Machines

To ensure that CNC drilling machines continue to operate at peak performance, regular maintenance is required. This includes regular cleaning and lubrication of the machine, as well as checking and replacing worn or damaged parts.

Additionally, CNC drilling machines should be calibrated on a regular basis to ensure that they are drilling holes to the correct depth and diameter. This is typically done using specialized software and sensors that monitor the drilling process and make adjustments as needed.

7. Safety Considerations

CNC drilling machines can be dangerous if not used properly. Operators should always follow safety guidelines and wear appropriate personal protective equipment such as goggles and gloves.

Additionally, the workpiece should be properly secured to prevent it from moving during the drilling process. This can be done using clamps or other specialized holding devices.

8. Choosing a CNC Drilling Machine

When choosing a CNC drilling machine, there are several factors to consider. These include the size and type of workpiece, the required hole size and shape, and the material being drilled.

Additionally, it is important to consider the machine’s accuracy and repeatability, as well as its speed and efficiency. The cost of the machine and its maintenance requirements should also be taken into account.

9. Conclusion

CNC drilling machines are a highly versatile and precise tool that is used in a wide range of industries. They offer several advantages over traditional drilling methods, including increased accuracy, automation, and the ability to drill a wider range of materials.

When choosing a CNC drilling machine, it is important to consider the specific needs of your application, as well as the machine’s accuracy, speed, and reliability. With proper maintenance and safety precautions, CNC drilling machines can provide many years of reliable service.

10. References

– “CNC Drilling Machine.” Wikipedia, The Free Encyclopedia. Wikimedia Foundation, Inc. Web. 22 Nov. 2021.

– “CNC Drilling Machines.” Thomasnet. Thomas. Web. 22 Nov. 2021.

– “What is CNC Drilling?” Woodworking Network. CCI Media, LLC. Web. 22 Nov. 2021.

Frequently Asked Questions

Here are some of the most frequently asked questions about how CNC drilling machine works.

What is a CNC drilling machine?

A CNC drilling machine is a computer-controlled machine tool used to drill holes in various materials. It is a highly precise and efficient tool that allows for faster and more accurate hole drilling and other operations.

The machine works by using a computer program to control the movement of the drill bit, which is mounted on a spindle that rotates at high speed. The program tells the machine where to drill, how deep to drill, and at what speed and feed rate.

What are the components of a CNC drilling machine?

A CNC drilling machine consists of several main components, including the spindle, the table, the drill bit, the control panel, and the computer system. The spindle is the part that rotates the drill bit, while the table holds the workpiece in place.

The drill bit is attached to the spindle and is used to create the hole. The control panel is used to input commands and control the movement of the machine, while the computer system stores and executes the program that controls the machine’s operations.

What materials can be drilled with a CNC drilling machine?

A CNC drilling machine can be used to drill holes in a wide range of materials, including metals, plastics, woods, and composites. The machine can be programmed to drill holes of different sizes and shapes, depending on the needs of the project.

The machine can also be used to perform other operations, such as tapping, reaming, and countersinking, which makes it a versatile tool for various applications.

How accurate is a CNC drilling machine?

A CNC drilling machine is highly accurate and precise, with tolerances up to a few microns. The machine can be programmed to drill holes with exact dimensions, ensuring that each hole is consistent and precise.

The accuracy of the machine depends on several factors, such as the quality of the machine, the programming, and the material being drilled. However, with proper maintenance and calibration, a CNC drilling machine can maintain its accuracy for many years.

What are the advantages of using a CNC drilling machine?

There are several advantages of using a CNC drilling machine, such as increased productivity, accuracy, and consistency. The machine can perform complex operations quickly and efficiently, which reduces the time and labor required for drilling holes.

The machine can also produce consistent and precise holes, which ensures that each part is identical and meets the required specifications. This reduces the risk of errors and defects, which can save time and money in the long run.

Tool Cutting manufacturing Drilling and Tapping CNC Machine. Tools Deep Drilling machining

In conclusion, CNC drilling machines have revolutionized the manufacturing industry by providing precise and efficient drilling solutions. These machines use computer numerical control to automate the drilling process, ensuring accuracy and speed. With the ability to drill a wide range of materials, CNC drilling machines are essential tools for various industries.

Moreover, the CNC drilling machine’s operation is simple and straightforward, making it easy for operators to use. The machines are equipped with various tools and attachments, making them adaptable to different drilling requirements. The CNC drilling machine’s ability to perform multiple drilling operations simultaneously is a significant advantage, reducing manufacturing time and increasing productivity.

Overall, the CNC drilling machine is a vital investment for any manufacturing company looking to improve their drilling process. With its precision, speed, and versatility, the CNC drilling machine is an essential tool for manufacturing high-quality products. As technology continues to advance, we can expect to see more innovative features integrated into these machines, making them even more efficient and reliable.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com