Table of Contents

- Freequently Asked Questions

- What type of blade should I use to cut aluminum extrusions with a miter saw?

- What safety precautions should I take when cutting aluminum extrusions with a miter saw?

- What is the best way to measure and mark aluminum extrusions for cutting with a miter saw?

- What is the best way to secure the aluminum extrusion to the miter saw for cutting?

- What is the best way to clean the aluminum extrusion after cutting it with a miter saw?

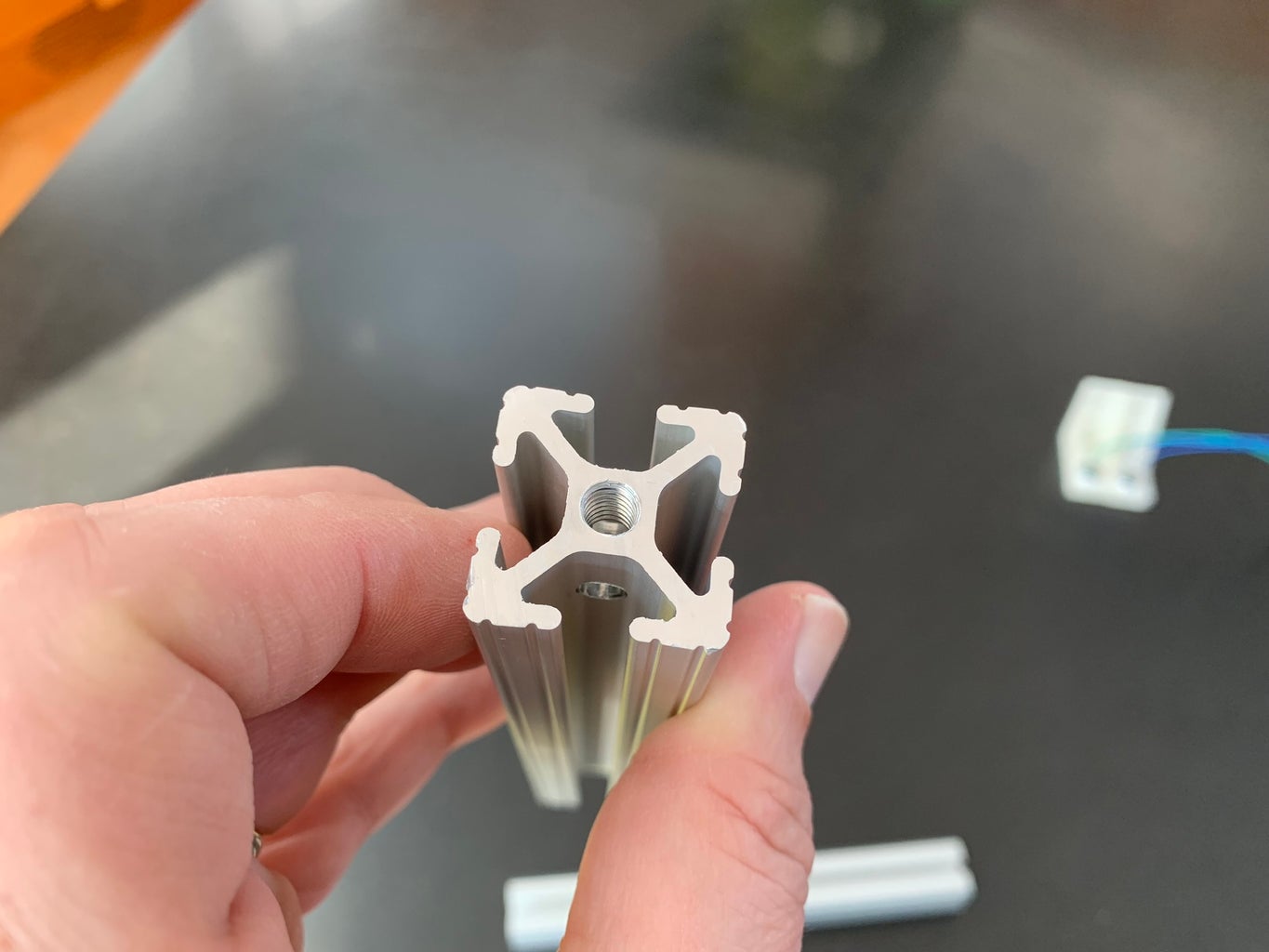

Are you looking to cut aluminum extrusions with a miter saw? If so, you’ve come to the right place. Cutting aluminum can be a bit tricky, but with the right tools and techniques, it can be done easily and efficiently.

In this article, we’ll provide you with step-by-step instructions on how to cut aluminum extrusions with a miter saw. We’ll cover everything from selecting the right blade to ensuring the safety of yourself and others. So, if you’re ready to learn how to cut aluminum extrusions like a pro, let’s get started!

To cut aluminum extrusions with a miter saw, you will need a blade with carbide tipped teeth. Set the saw at a 90-degree angle, clamp the extrusion to the saw base, and turn on the saw. Slowly lower the blade onto the extrusion and cut through it in one motion. Always wear safety goggles and protective gloves when cutting aluminum extrusions.

How to Cut Aluminum Extrusions With a Miter Saw – A Comprehensive Guide

If you are planning to cut aluminum extrusions with a miter saw, you should know that it is not as simple as cutting wood. Aluminum extrusions need to be cut with precision, and the process requires a certain level of expertise. In this article, we will guide you through the process of cutting aluminum extrusions with a miter saw, step by step.

Step 1: Choose the Right Blade

Choosing the right blade is crucial when it comes to cutting aluminum extrusions with a miter saw. You need to use a blade that is specifically designed for cutting non-ferrous metals like aluminum. A blade with a high tooth count (around 80) and carbide tips is ideal for the job.

Once you have the right blade, you need to install it correctly on your miter saw. Make sure the blade is tightened securely and that it is aligned properly with the saw.

Step 2: Measure and Mark the Aluminum Extrusion

Before you start cutting, you need to measure and mark the aluminum extrusion accurately. Use a measuring tape to mark the length of the extrusion that needs to be cut, and a square to ensure that the cut is at a 90-degree angle.

It is also a good idea to mark the waste side of the cut, so you don’t accidentally cut the wrong section of the extrusion.

Step 3: Prepare the Miter Saw

Once you have measured and marked the aluminum extrusion, you need to prepare the miter saw. Adjust the blade angle to match the angle of the cut you need to make. Make sure the saw is unplugged before you make any adjustments.

You should also adjust the height of the blade so that it is just above the aluminum extrusion. This will help to prevent the blade from binding and causing damage to the saw.

Step 4: Secure the Aluminum Extrusion

Before you start cutting, you need to secure the aluminum extrusion to the miter saw. Use clamps or a vise to hold the extrusion securely in place. This will prevent it from moving or vibrating during the cutting process.

Make sure the extrusion is positioned correctly on the saw, and that it is aligned with the blade.

Step 5: Make the Cut

Now it’s time to make the cut. Turn on the miter saw and slowly lower the blade onto the aluminum extrusion. Use a steady, even pressure to make the cut, and make sure you are following the marked line accurately.

Do not force the blade through the aluminum extrusion, as this can cause the blade to bind and potentially damage the saw.

Step 6: Inspect the Cut

Once you have made the cut, inspect it carefully to ensure that it is straight and clean. If there are any rough edges or burrs, use a metal file or sandpaper to smooth them out.

Step 7: Repeat the Process

If you need to make multiple cuts, repeat the process for each cut. Make sure you adjust the blade angle and height for each cut, and that you are using the same level of pressure each time.

Step 8: Clean up the Work Area

Once you have finished cutting the aluminum extrusions, clean up the work area. Remove any debris or scrap pieces of aluminum, and wipe down the saw and work surface with a clean cloth.

Step 9: Store the Saw and Blade Safely

After you have finished using the saw, make sure you store it and the blade safely. Unplug the saw, and remove the blade carefully. Store the blade in a protective case, and keep the saw in a dry, secure location.

Step 10: Benefits of Cutting Aluminum Extrusions with a Miter Saw

Cutting aluminum extrusions with a miter saw has several benefits. It allows for precise cuts, which is important when working with metals. It also saves time and effort compared to cutting by hand. Plus, it produces clean, straight cuts that require minimal finishing.

Vs.

When compared to other methods of cutting aluminum extrusions, such as a hacksaw or a bandsaw, a miter saw is faster and more efficient. It also produces fewer burrs and rough edges, which reduces the need for additional finishing work.

In conclusion, cutting aluminum extrusions with a miter saw requires the right blade, precise measurements, and careful attention to safety. However, with the right tools and techniques, it is a fast and efficient way to produce precise, clean cuts.

Freequently Asked Questions

Aluminum extrusions are often used for a variety of projects and cutting them to the desired length is an important part of the process. Using a miter saw is a popular method for cutting aluminum extrusions. Here are some frequently asked questions about how to cut aluminum extrusions with a miter saw.

What type of blade should I use to cut aluminum extrusions with a miter saw?

When cutting aluminum extrusions with a miter saw, it is important to use a blade that is designed for cutting non-ferrous metals. These blades have a special coating that prevents the aluminum from sticking to the blade and causing kickback. It is recommended that you use a 60-tooth or 80-tooth blade for optimal results.

Make sure the blade is secured tightly on the miter saw and that the blade is sharp. Dull blades can cause the aluminum to warp, which can affect the accuracy of your cuts.

What safety precautions should I take when cutting aluminum extrusions with a miter saw?

When cutting aluminum extrusions with a miter saw, it is important to wear safety glasses to protect your eyes from flying debris. You should also wear ear protection to prevent hearing damage from the loud noise of the saw. Always keep your hands and fingers away from the blade and make sure to use a clamp to hold the aluminum securely in place.

It is also important to work in a well-ventilated area to avoid inhaling aluminum dust, which can be harmful to your health. Always follow the manufacturer’s safety guidelines when using a miter saw to cut aluminum extrusions.

What is the best way to measure and mark aluminum extrusions for cutting with a miter saw?

Before cutting aluminum extrusions with a miter saw, it is important to measure and mark where you want to make your cuts. Use a measuring tape to determine the length of the extrusion and use a square to mark where you want to make your cuts.

Make sure to double-check your measurements before making any cuts. It is also a good idea to make a test cut on a scrap piece of aluminum to ensure that your measurements are correct before making any final cuts on your project material.

What is the best way to secure the aluminum extrusion to the miter saw for cutting?

When cutting aluminum extrusions with a miter saw, it is important to secure the material to the saw to prevent it from moving during the cut. Use clamps to hold the aluminum extrusion securely in place on the miter saw’s table.

Make sure the extrusion is aligned properly with the blade before making your cut. This will ensure that your cuts are accurate and straight. If the aluminum extrusion is not secure, it can cause the blade to bind or kick back, which is dangerous and can damage your material or saw.

What is the best way to clean the aluminum extrusion after cutting it with a miter saw?

After cutting aluminum extrusions with a miter saw, it is important to clean the material to remove any debris or dust that may be left behind. Use a soft-bristled brush or a vacuum to remove any loose debris from the material.

You can also use a degreaser or rubbing alcohol to clean the aluminum extrusion. Apply the cleaner to a soft cloth and wipe down the material. This will help to remove any grease or oil that may be on the surface of the material and leave it looking clean and shiny.

In conclusion, cutting aluminum extrusions with a miter saw is not as complicated as it seems. By following the proper steps and using the right tools, you can achieve precise and accurate cuts every time. With a little practice, you’ll quickly become an expert in cutting aluminum extrusions with your miter saw.

Remember to always prioritize safety when working with power tools. Wear protective gear, and follow the safety instructions that come with your miter saw. With the right mindset and safety measures in place, you can confidently take on any cutting project with your miter saw.

Lastly, be sure to take your time and measure twice before making any cuts. Accuracy is key when working with aluminum extrusions, and even a small mistake can cause major issues. By taking your time and double-checking your measurements, you’ll save yourself time and frustration in the long run. So go ahead, get started with your aluminum extrusion cutting project, and enjoy the satisfaction of a job well done.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com