Table of Contents

Rubber is an incredibly versatile material that is used in a wide range of products, from car tires to shoe soles. But can rubber be injection molded? This is a question that many people have been asking, and the answer is yes! Injection molding is one of the most common methods used to manufacture rubber products, and it offers a number of benefits over other methods.

Injection molding allows for the production of complex shapes and designs with high precision and consistency. This makes it an ideal method for producing rubber products that require a high level of accuracy and consistency, such as seals, gaskets, and O-rings. In this article, we will explore the process of injection molding rubber, the benefits of this method, and some of the challenges that can arise when working with this material.

Yes, rubber can be injection molded. Injection molding is a popular method used to create rubber parts with high precision and consistency. The process involves heating the rubber until it becomes molten and then injecting it into a mold cavity. Once the rubber has cooled and solidified, the mold is opened to release the finished part. Injection molding is commonly used in the automotive, medical, and electronics industries to produce various rubber components.

Can Rubber Be Injection Molded?

Injection molding is a popular manufacturing process that involves injecting molten material into a mold to create a wide range of products. However, when it comes to rubber, many people wonder if it can be injection molded. In this article, we’ll explore the answer to that question and provide some insights into the injection molding process for rubber.

What is Injection Molding?

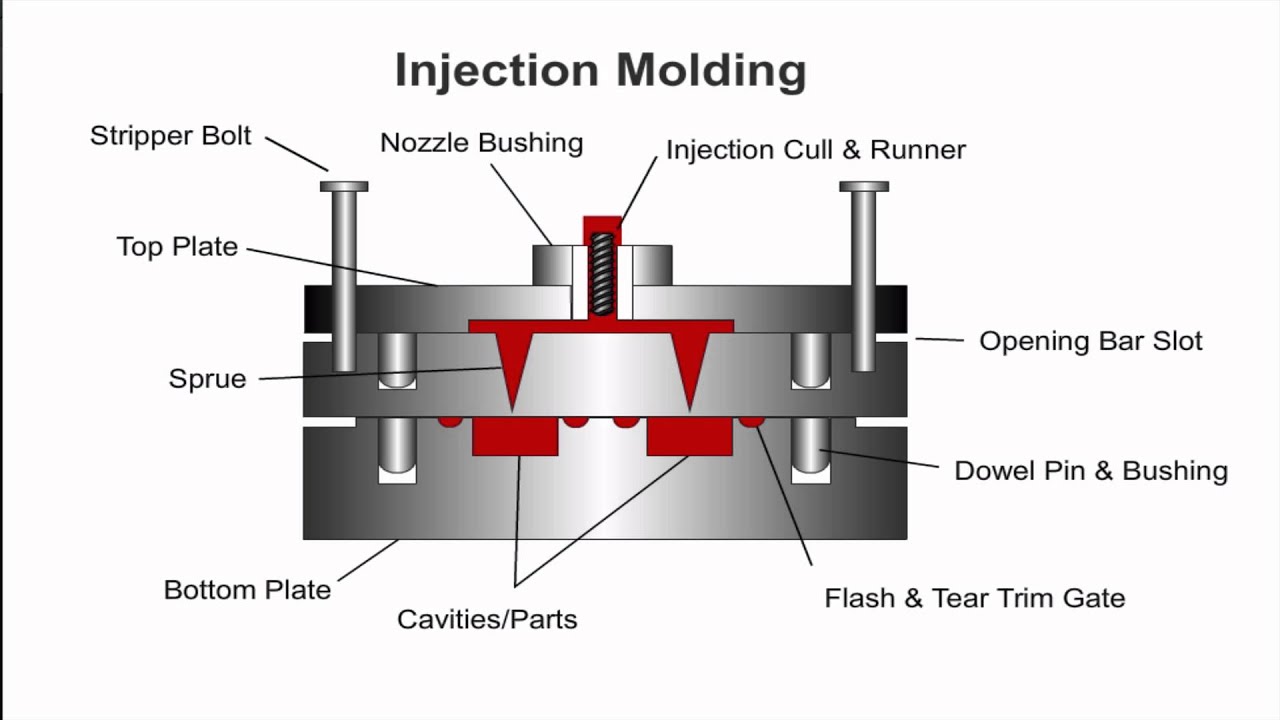

Injection molding is a manufacturing process that involves injecting molten material into a mold to create a product. The process is widely used for producing plastic products, but it can also be used for other materials such as rubber. The process involves several steps:

- Melting the material

- Injecting the material into a mold

- Cooling the mold to solidify the material

- Removing the product from the mold

The process is highly efficient and produces high-quality products with great accuracy and consistency.

Can Rubber Be Injection Molded?

The answer is yes, rubber can be injection molded. However, the process is slightly different from plastic injection molding. Rubber injection molding involves melting rubber pellets or raw rubber and injecting the molten rubber into a mold. The mold is then cooled to solidify the rubber, and the product is removed from the mold.

Rubber injection molding is widely used for producing a wide range of rubber products such as seals, gaskets, O-rings, and more. The process offers several benefits such as high accuracy, consistency, and cost-effectiveness.

The Benefits of Rubber Injection Molding

There are several benefits to using rubber injection molding for producing rubber products. Some of these benefits include:

- High accuracy and consistency

- Cost-effectiveness

- Fast production times

- Ability to produce complex shapes and designs

- Reduced waste and scrap material

The process is also highly customizable, allowing manufacturers to produce products in a wide range of shapes, sizes, and colors. Additionally, rubber injection molding can be used for producing both small and large quantities of products.

Rubber Injection Molding vs. Other Rubber Manufacturing Processes

There are several other manufacturing processes for producing rubber products. Some of the most common processes include compression molding, transfer molding, and injection transfer molding. While each of these processes has its own advantages and disadvantages, rubber injection molding offers several benefits over the other processes.

For example, rubber injection molding offers higher accuracy and consistency compared to compression molding. Additionally, the process offers faster production times compared to transfer molding. Injection transfer molding, on the other hand, requires a pre-form to be made, making it less cost-effective compared to rubber injection molding.

Conclusion

Rubber injection molding is a highly efficient and cost-effective manufacturing process for producing a wide range of rubber products. The process offers several benefits such as high accuracy and consistency, fast production times, and the ability to produce complex shapes and designs. While there are several other manufacturing processes for producing rubber products, rubber injection molding offers several advantages over the other processes. If you’re considering rubber injection molding for your manufacturing needs, be sure to choose a reputable manufacturer with experience in the process.

Frequently Asked Questions

Can rubber be injection molded?

Yes, rubber can be injection molded. Injection molding is a process used to manufacture parts by injecting molten material into a mold. Rubber injection molding is a process used to produce rubber parts, such as seals, gaskets, and O-rings. The process involves heating rubber material, injecting it into a mold, and allowing it to cool and solidify.

Rubber injection molding is a cost-effective and efficient way to produce high-quality rubber parts. It allows for precise control over the shape, size, and properties of the finished product. The process can also be used to produce parts with complex shapes or intricate details that would be difficult or impossible to produce using other methods.

What are the advantages of rubber injection molding?

Rubber injection molding offers several advantages over other methods of rubber part production. One of the main advantages is the ability to produce high-quality parts with consistent properties. The process allows for precise control over the material properties, which results in parts that are more durable and reliable.

Another advantage of rubber injection molding is the ability to produce parts with complex shapes or intricate details. The process can be used to produce parts with thin walls, undercuts, and other features that would be difficult or impossible to produce using other methods.

What types of rubber can be used for injection molding?

A wide range of rubber materials can be used for injection molding, including natural rubber, synthetic rubber, and silicone rubber. The choice of material will depend on the specific application and performance requirements of the part.

Natural rubber is a popular choice for injection molding because it offers excellent elasticity and resilience. Synthetic rubbers, such as Nitrile, EPDM, and Viton, offer improved resistance to heat, chemicals, and other environmental factors. Silicone rubber is also commonly used for injection molding because it offers excellent heat resistance and flexibility.

What is the process for rubber injection molding?

The process for rubber injection molding involves several steps. First, the rubber material is heated to a molten state and then injected into a mold under high pressure. The mold is then cooled, and the part is removed from the mold.

The process requires specialized equipment, including an injection molding machine and a mold. The mold is typically made from steel or aluminum and is designed to produce the desired part shape. The injection molding machine uses a screw or plunger to inject the molten rubber into the mold under high pressure.

What are some common applications for rubber injection molded parts?

Rubber injection molded parts are used in a wide range of applications, including automotive, aerospace, medical, and industrial applications. Some common applications include seals, gaskets, O-rings, diaphragms, and vibration dampers.

Rubber injection molded parts are often used in applications where a high degree of precision and reliability are required. They are also commonly used in applications where resistance to heat, chemicals, and other environmental factors is important. Overall, rubber injection molding is a versatile and cost-effective way to produce high-quality rubber parts for a wide range of applications.

In conclusion, rubber can indeed be injection molded, making it a versatile material that can be used in a variety of applications. The injection molding process involves heating the rubber to a molten state and injecting it into a mold, where it cools and solidifies to the desired shape.

One of the benefits of injection molding rubber is its ability to create complex shapes and precise details. This makes it ideal for manufacturing products such as seals, gaskets, and other components that require a high level of accuracy.

Additionally, injection molding rubber allows for increased efficiency and cost-effectiveness in the manufacturing process. By using automated machinery and standardized molds, large quantities of products can be produced quickly and with minimal waste.

Overall, the injection molding of rubber offers numerous advantages over other manufacturing methods, making it a popular choice for a wide range of industries.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com