Table of Contents

Centrifugal die casting is a manufacturing process that has gained popularity in recent years due to its ability to produce high-quality, complex shaped metal parts. This process involves pouring molten metal into a spinning mold, which results in a uniform and dense product.

Unlike traditional die casting methods, centrifugal die casting can produce parts with thinner walls, tighter tolerances, and fewer porosities. This makes it an ideal choice for industries such as aerospace, automotive, and medical, where precision and reliability are crucial. In this article, we will explore the basics of centrifugal die casting and its many advantages.

What is Centrifugal Die Casting?

Centrifugal die casting is a process of manufacturing metal parts by pouring molten metal into a spinning die. The centrifugal force caused by the spinning motion distributes the molten metal evenly throughout the die, resulting in a high-quality, dense, and defect-free part. This process is widely used in the production of cylindrical parts such as pipes, wheels, and gears that require high precision and strength.

The Process of Centrifugal Die Casting

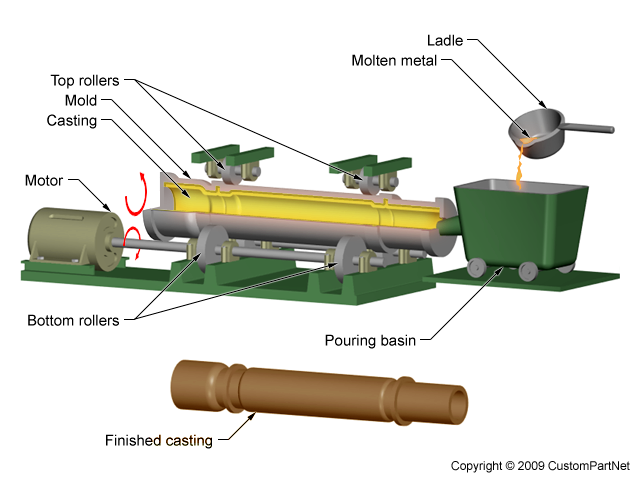

Centrifugal die casting involves several steps, including mold preparation, metal melting, pouring, solidification, and ejection.

In the mold preparation stage, a cylindrical die is placed on a spinning axis. The die can be made of steel, iron, or graphite, depending on the type of metal being cast. The die is then coated with a lubricant to prevent the molten metal from sticking to the surface.

In the metal melting stage, the raw material is melted using a furnace or an induction heater. The temperature and time of melting depend on the type of metal being cast. The molten metal is then poured into the die through a sprue.

As the molten metal is poured into the spinning die, the centrifugal force distributes it evenly throughout the mold. The molten metal solidifies quickly due to the high-speed spinning, resulting in a dense and defect-free part.

After the solidification stage, the ejection process begins. The die is removed from the spinning axis, and the part is ejected from the die using a hydraulic or mechanical press. The part is then trimmed and finished to meet the required specifications.

The Advantages of Centrifugal Die Casting

Centrifugal die casting offers several advantages over other casting methods, including:

1. High Precision: The centrifugal force distributes the molten metal evenly throughout the die, resulting in a high-precision part.

2. High Strength: The dense and defect-free structure of the part provides high strength and durability.

3. Cost-Effective: The process is highly automated, reducing labor costs and increasing productivity.

4. Versatility: The process can be used to cast a wide range of metals, including aluminum, copper, and stainless steel.

5. Reduced Waste: The process minimizes material waste by using only the required amount of metal.

Centrifugal Die Casting vs. Other Casting Methods

Centrifugal die casting offers several advantages over other casting methods, including:

1. Sand Casting: Centrifugal die casting produces parts with a much finer surface finish than sand casting.

2. Investment Casting: Centrifugal die casting is faster and more cost-effective than investment casting.

3. Permanent Mold Casting: Centrifugal die casting is more versatile than permanent mold casting and can produce larger parts.

4. Die Casting: Centrifugal die casting is more suitable for complex and large parts than die casting.

Conclusion

Centrifugal die casting is a highly precise and cost-effective manufacturing method that offers several advantages over other casting methods. The process involves pouring molten metal into a spinning die, resulting in a dense and defect-free part. This process is widely used in the production of cylindrical parts that require high precision and strength.

Frequently Asked Questions

In this section, we will answer some of the most common questions about centrifugal die casting.

What is centrifugal die casting?

Centrifugal die casting is a casting process that involves the use of centrifugal force to cast metal parts. The process involves pouring molten metal into a rotating die, and the centrifugal force pushes the molten metal towards the die walls, resulting in a uniform and dense casting. This process is used to produce complex and intricate parts that cannot be produced using other casting methods.

Centrifugal die casting is commonly used in the aerospace, automotive, and medical industries for the production of parts such as turbine blades, gears, and medical implants. It is a highly efficient and cost-effective method of producing high-quality metal parts with minimal waste.

What are the benefits of centrifugal die casting?

One of the main benefits of centrifugal die casting is its ability to produce high-quality, dense metal parts with minimal porosity. This method of casting also allows for the production of complex and intricate parts that cannot be produced using other casting methods.

Centrifugal die casting is also a highly efficient process, as it allows for the production of large quantities of parts in a short amount of time. Additionally, this process is highly customizable, as it allows for the use of different metals and alloys to produce parts with specific properties and characteristics.

What types of metals can be used in centrifugal die casting?

A wide range of metals and alloys can be used in centrifugal die casting, including aluminum, brass, bronze, copper, and stainless steel. The choice of metal will depend on the specific application and the desired properties of the finished part.

For example, aluminum is commonly used in the aerospace industry for the production of lightweight parts, while brass and bronze are often used in the manufacturing of musical instruments and decorative items.

What are some common applications of centrifugal die casting?

Centrifugal die casting is used in a wide range of industries for the production of various parts and components. Some common applications of this casting method include the production of turbine blades and other aerospace components, automotive parts such as gears and engine components, and medical implants such as hip replacements and dental implants.

This method of casting is also commonly used in the production of decorative items such as jewelry, statues, and sculptures, as well as in the manufacturing of musical instruments such as cymbals and bells.

What are the limitations of centrifugal die casting?

While centrifugal die casting offers many benefits, it also has some limitations. One of the main limitations is the size of the parts that can be produced using this method. Parts larger than a certain size may not be able to be cast using this method, as the centrifugal force required to cast the part may be too great.

Additionally, the complexity of the parts that can be produced using centrifugal die casting is limited by the design of the die. Parts with intricate shapes or features may require multiple dies or other casting methods to produce.

In conclusion, centrifugal die casting is a highly specialized technique used in the manufacturing industry to produce high-quality metal parts. With this technique, molten metal is poured into a spinning mold, allowing the centrifugal force to distribute the metal evenly, resulting in a finished product that is free of porosity and other defects.

Centrifugal die casting is often used in the production of aerospace components, automotive parts, and medical equipment. By using this technique, manufacturers can create complex shapes and achieve tight tolerances, ensuring that the finished product meets the strictest specifications.

Overall, centrifugal die casting is a valuable tool in the manufacturing industry, allowing businesses to produce high-quality metal parts efficiently and effectively. As technology continues to advance, we can expect to see even more innovative applications of this technique in the years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com