Table of Contents

Injection molding is a highly efficient and cost-effective manufacturing process that has revolutionized the production of plastic parts. However, one of the biggest challenges faced by injection molders is the formation of silver streaks. These streaks are an unsightly defect that can compromise the quality and functionality of the finished product.

Fortunately, there are several strategies that can be employed to prevent silver streaks from forming in injection molding. By understanding the causes of this defect and implementing best practices, molders can ensure that their products are of the highest quality and meet the expectations of their customers. In this article, we will explore some of the most effective ways to avoid silver streaks in injection molding and achieve flawless, high-quality parts.

To avoid silver streaks in injection molding, follow these steps:

- Clean the mold surface to remove all contaminants

- Adjust the temperature and pressure according to the resin being used

- Increase the injection speed to reduce residence time

- Use a mold release agent to prevent sticking

- Ensure proper venting to release trapped air

- Use a high-quality resin with consistent melt flow

- Avoid overheating the resin to prevent degradation

By following these steps, you can prevent silver streaks from appearing in your injection-molded parts.

How to Avoid Silver Streaks in Injection Molding?

Silver streaks in injection molding can be frustrating and time-consuming to deal with. They can result in defective parts and delays in production. However, with the right techniques and precautions, they can be avoided altogether. Here are ten tips to help you avoid silver streaks in injection molding.

1. Clean and Maintain the Molding Machine

To avoid silver streaks, it is important to keep the molding machine clean and well-maintained. Regular cleaning and maintenance will prevent any buildup of residue or contaminants that may cause silver streaks. Make sure to follow the manufacturer’s instructions for cleaning and maintenance.

It is also important to keep the mold clean and free of any debris or contaminants. Any residue left on the mold can transfer onto the part and cause silver streaks. Clean the mold after every use and inspect it for any signs of wear or damage.

2. Use High-Quality Resins

Using high-quality resins is crucial in preventing silver streaks. Cheap or low-quality resins may contain impurities or contaminants that can cause silver streaks. Make sure to use resins from a reputable supplier and follow their recommendations for processing.

3. Ensure Proper Drying of Resins

Moisture in the resin can cause silver streaks during injection molding. Make sure to dry the resin properly before processing. Follow the resin manufacturer’s recommendations for drying time and temperature.

4. Check and Adjust Injection Speed and Pressure

The injection speed and pressure can also affect the occurrence of silver streaks. Too high of a speed or pressure can cause the resin to shear and create silver streaks. Make sure to check and adjust the injection speed and pressure to the recommended levels for the resin being used.

5. Optimize the Cooling System

The cooling system can also affect the occurrence of silver streaks. If the cooling time is too short or the temperature is too high, it can cause the part to warp or create silver streaks. Make sure to optimize the cooling system for the resin being used.

6. Use Proper Injection Molding Parameters

Proper injection molding parameters can also help prevent silver streaks. Make sure to use the recommended parameters for the resin being used. This includes the temperature, pressure, and speed settings.

7. Avoid Overpacking the Mold

Overpacking the mold can also cause silver streaks. This is when too much resin is injected into the mold, causing the part to warp or create silver streaks. Make sure to follow the recommended resin weight and pack pressure for the mold being used.

8. Use Release Agents Properly

Release agents are used to prevent the part from sticking to the mold. However, if too much release agent is used or it is not applied properly, it can cause silver streaks. Make sure to follow the manufacturer’s instructions for applying release agents.

9. Inspect Parts Regularly

Regular inspection of parts can help catch any silver streaks early on. Make sure to inspect the parts for any defects or imperfections. If silver streaks are found, make sure to adjust the injection molding parameters accordingly.

10. Train Operators on Best Practices

Proper training of operators is crucial in preventing silver streaks. Make sure to train operators on the best practices for injection molding, including proper cleaning and maintenance, resin drying, injection molding parameters, and inspection techniques.

In conclusion, silver streaks in injection molding can be avoided with the right techniques and precautions. By following these ten tips, you can ensure that your parts are free of silver streaks and meet the highest quality standards.

Frequently Asked Questions

In injection molding, silver streaks are a common problem that can occur during the process. These streaks are unsightly and can affect the quality of the final product. Here are some frequently asked questions on how to avoid silver streaks in injection molding.

What are silver streaks in injection molding?

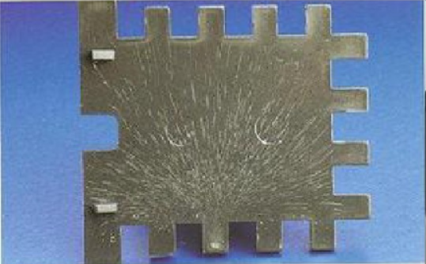

Silver streaks are marks or streaks that appear on the surface of a molded part, typically silver or gray in color. They are caused by the presence of unmixed or improperly mixed resin in the material being injected into the mold. The streaks can be caused by a variety of factors, including temperature, pressure, and mold design.

To avoid silver streaks, it is important to ensure that the resin is properly mixed and that the injection molding process is carefully controlled. This may involve adjusting the temperature and pressure of the machine, as well as making changes to the mold design or material used.

What causes silver streaks in injection molding?

Silver streaks can be caused by a number of factors, including the presence of unmixed or improperly mixed resin in the material being injected into the mold. This can be caused by a variety of factors, including temperature, pressure, and mold design. Other factors that can contribute to silver streaks include inadequate cooling time, inadequate venting, and poor mold release.

To avoid silver streaks, it is important to carefully monitor and control the injection molding process. This may involve making adjustments to the temperature and pressure of the machine, as well as making changes to the mold design or material used. It may also be necessary to adjust the cooling time or provide better venting to allow for proper release of gases during the molding process.

How can silver streaks be detected in injection molding?

Silver streaks can be detected by visually inspecting the surface of the molded part. These streaks will be silver or gray in color and may be present in a variety of patterns or shapes. In some cases, the streaks may be visible only under certain lighting conditions or at certain angles.

To avoid silver streaks, it is important to carefully monitor and control the injection molding process. This may involve making adjustments to the temperature and pressure of the machine, as well as making changes to the mold design or material used. It may also be necessary to adjust the cooling time or provide better venting to allow for proper release of gases during the molding process.

What are the consequences of silver streaks in injection molding?

Silver streaks can have a number of negative consequences in injection molding. These streaks can affect the appearance of the final product, making it look unsightly or unprofessional. In addition, silver streaks can weaken the molded part, reducing its strength or durability. This can lead to the part failing or breaking under stress, which can be dangerous in some applications.

To avoid silver streaks, it is important to carefully monitor and control the injection molding process. This may involve making adjustments to the temperature and pressure of the machine, as well as making changes to the mold design or material used. It may also be necessary to adjust the cooling time or provide better venting to allow for proper release of gases during the molding process.

What steps can be taken to prevent silver streaks in injection molding?

To prevent silver streaks in injection molding, it is important to carefully monitor and control the injection molding process. This may involve making adjustments to the temperature and pressure of the machine, as well as making changes to the mold design or material used. It may also be necessary to adjust the cooling time or provide better venting to allow for proper release of gases during the molding process.

Other steps that can be taken to prevent silver streaks include thoroughly mixing the resin before injection, using high-quality materials, and ensuring that the mold is clean and free of debris. It is also important to properly maintain and clean the injection molding machine to prevent contamination and ensure consistent performance.

In conclusion, avoiding silver streaks in injection molding can be achieved through proper machine maintenance and material selection. Regular cleaning and inspection of the machine’s nozzle and barrel can prevent buildup and contamination that may cause silver streaks. Additionally, selecting the right materials with appropriate additives and processing parameters can improve the flow and reduce the risk of silver streaking.

Moreover, implementing a comprehensive quality control process can also help identify and address silver streak issues early on. This includes monitoring the injection molding process, conducting visual inspections, and performing tests to ensure the final product meets the required specifications.

Ultimately, by following these tips and best practices, manufacturers can minimize the occurrence of silver streaks, improve product quality, and increase customer satisfaction. So, take the necessary steps to avoid silver streaks and produce high-quality injection-molded products.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com