Table of Contents

- Increasing Productivity in Injection Molding

- 1. Optimize the Mold Design

- 2. Use High-Quality Materials

- 3. Maintain Proper Machine Settings

- 4. Implement Process Monitoring and Control

- 5. Use Automation and Robotics

- 6. Implement Lean Manufacturing Principles

- 7. Train and Educate Employees

- 8. Regular Maintenance and Cleaning

- 9. Use Statistical Process Control

- 10. Continuously Improve the Process

- Frequently Asked Questions

- What are some ways to reduce cycle time in injection molding?

- How can I improve the quality of my injection molded parts?

- What role does automation play in increasing productivity in injection molding?

- What are some common challenges in injection molding and how can they be addressed?

- How can I optimize my injection molding process to increase productivity?

As the demand for high-quality products increases, the pressure on manufacturers to produce more efficiently is greater than ever before. This is particularly true in injection molding, where even the slightest inefficiency can lead to significant delays and losses. Fortunately, there are several proven strategies that can help increase productivity and streamline processes in the injection molding industry.

From optimizing machine settings and improving material flow to implementing automated systems and leveraging data analytics, there are various ways to boost productivity in injection molding. In this article, we will explore some of the most effective methods that manufacturers can use to enhance their operations and stay competitive in today’s fast-paced market.

How to Increase Productivity in Injection Molding?

1. Optimize your mold design to reduce cycle time.

2. Use high-quality materials to reduce scrap rates.

3. Implement automation to reduce downtime.

4. Regularly maintain and service machinery to prevent breakdowns.

5. Train employees on proper operating procedures and safety protocols.

Increasing Productivity in Injection Molding

Injection molding is a popular manufacturing process used to produce a wide range of products. While the process can be efficient, there are always ways to improve productivity. In this article, we will discuss 10 ways to increase productivity in injection molding.

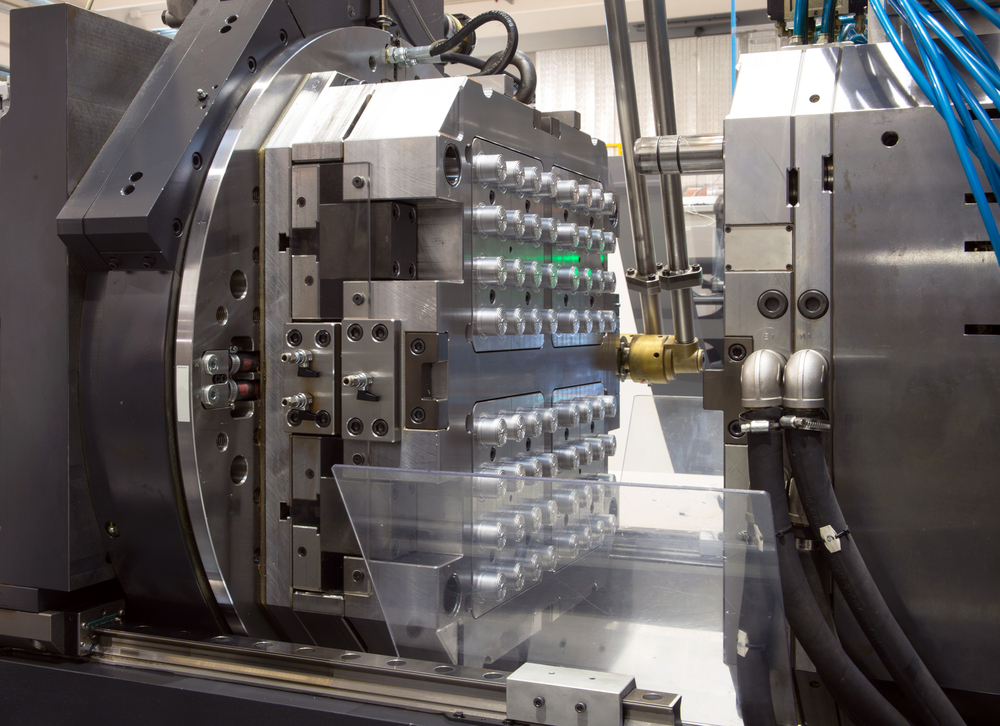

1. Optimize the Mold Design

The design of the mold is one of the most critical factors that determine the success of injection molding. A poorly designed mold can result in slower production times, higher material waste, and more frequent downtime due to mold defects. To optimize the mold design, it’s essential to consider the following factors:

– Part geometry

– Material selection

– Cooling system

– Runner system

– Ejector system

By optimizing the mold design, you can improve the efficiency and quality of the injection molding process.

2. Use High-Quality Materials

The quality of the material used in injection molding has a significant impact on the final product’s quality and the production efficiency. High-quality materials can reduce the risk of material waste and mold defects, resulting in less downtime and higher production rates.

3. Maintain Proper Machine Settings

The machine settings for injection molding can significantly affect productivity. To ensure the machine settings are optimal, it’s crucial to:

– Check the melt temperature regularly

– Monitor the cooling system

– Adjust the injection pressure and speed as needed

– Maintain the correct screw speed and backpressure

By keeping the machine settings in check, you can reduce the risk of mold defects and improve production efficiency.

4. Implement Process Monitoring and Control

Process monitoring and control systems can help identify and correct issues in real-time, reducing the risk of production downtime and defects. These systems can provide valuable data on the injection molding process, including temperature, pressure, and flow rate.

5. Use Automation and Robotics

Automation and robotics have become increasingly popular in injection molding. These systems can improve productivity by reducing downtime and increasing the accuracy of the molding process. They can also handle repetitive tasks, freeing up human resources for more complex tasks.

6. Implement Lean Manufacturing Principles

Lean manufacturing principles can help reduce waste and increase efficiency in the injection molding process. By implementing methods such as just-in-time manufacturing, continuous improvement, and value stream mapping, you can improve productivity and reduce costs.

7. Train and Educate Employees

Well-trained employees can make a significant difference in the injection molding process’s productivity. By providing regular training and education, you can ensure that your employees are up-to-date on the latest techniques, equipment, and safety practices.

8. Regular Maintenance and Cleaning

Regular maintenance and cleaning can help reduce downtime and prevent mold defects. By keeping the injection molding machine and mold clean and well-maintained, you can improve the quality of the final product and the efficiency of the process.

9. Use Statistical Process Control

Statistical process control is a method used to monitor and control the injection molding process’s quality. By using data and statistical analysis, you can identify trends, detect defects, and make adjustments to the process in real-time.

10. Continuously Improve the Process

Continuous improvement is a vital component of increasing productivity in injection molding. By regularly reviewing the process, identifying areas for improvement, and implementing changes, you can improve the efficiency and quality of the injection molding process over time.

In conclusion, increasing productivity in injection molding requires careful attention to the mold design, material selection, machine settings, process monitoring and control, automation and robotics, lean manufacturing, employee training, maintenance and cleaning, statistical process control, and continuous improvement. By implementing these strategies, you can improve the efficiency and quality of your injection molding process and stay competitive in today’s market.

Frequently Asked Questions

Injection molding is a complex process that requires attention to detail, efficiency, and productivity. Here are some frequently asked questions about how to increase productivity in injection molding.

What are some ways to reduce cycle time in injection molding?

Reducing cycle time in injection molding is a critical step in increasing productivity. One way to reduce cycle time is to optimize the injection molding process, including the injection speed, packing pressure, and cooling time. Another way is to use high-speed injection molding machines and advanced robotics to reduce the time it takes to remove parts from the mold.

Additionally, using hot runners and multi-cavity molds can also help reduce cycle time. Hot runners eliminate the need for runners and gates, while multi-cavity molds produce multiple parts in a single cycle, reducing the overall cycle time.

How can I improve the quality of my injection molded parts?

To improve the quality of injection molded parts, it is essential to have a thorough understanding of the injection molding process. This includes optimizing the injection molding parameters, such as temperature, pressure, and speed, to achieve the desired quality standards.

Additionally, using high-quality materials, maintaining the injection molding machine, and properly designing the mold can all improve the quality of injection molded parts. Regular inspections and quality control measures can also help identify and address any quality issues before they become major problems.

What role does automation play in increasing productivity in injection molding?

Automation plays a critical role in increasing productivity in injection molding. Automated systems, such as robots and conveyors, can help streamline the manufacturing process and improve efficiency. For example, robots can be used to remove parts from the mold, transport them to the next stage of production, and even perform quality control checks.

Additionally, automated systems can help reduce the risk of human error and improve consistency, leading to higher quality parts and increased productivity. Investing in automation can also help reduce labor costs and free up employees to focus on more skilled tasks.

What are some common challenges in injection molding and how can they be addressed?

Some common challenges in injection molding include defects in the finished parts, mold damage, and machine downtime. These challenges can be addressed through regular maintenance of the injection molding machine and mold, as well as implementing quality control measures and identifying and addressing any issues early on.

Additionally, using advanced technologies, such as real-time monitoring and predictive maintenance, can help identify potential issues before they cause significant problems, improving efficiency and productivity.

How can I optimize my injection molding process to increase productivity?

There are several ways to optimize the injection molding process to increase productivity. One way is to use simulation software to test different injection molding parameters and identify the optimal settings for your specific application. Additionally, regularly monitoring and analyzing production data can help identify areas for improvement and optimize the process accordingly.

Investing in advanced technologies, such as real-time monitoring and predictive maintenance, can also help improve efficiency and productivity by identifying and addressing issues early on. Finally, regularly training employees on the latest technologies and best practices can help ensure that your injection molding process is always operating at peak efficiency.

In conclusion, increasing productivity in injection molding requires a multifaceted approach. First, optimizing process parameters such as temperature, pressure, and cycle time can significantly improve efficiency. Second, implementing automation and robotics can reduce human error and increase throughput. Finally, investing in employee training and development can improve overall knowledge and skill levels, leading to more efficient and effective production.

By taking these steps, injection molding companies can improve their bottom line while also producing higher quality products. While there may be initial costs associated with implementing these changes, the long-term benefits will far outweigh any initial expenses.

In today’s competitive market, it is more important than ever to prioritize productivity and efficiency. By following these guidelines, injection molding companies can stay ahead of the curve and remain competitive in the industry. With the right tools, technology, and training, the possibilities are endless.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com