Table of Contents

- How to Change Spindle Speeds in CNC Lathe?

- Step 1: Understand the Spindle Speed Range

- Step 2: Select the Tool and Material

- Step 3: Access the Spindle Speed Control

- Step 4: Check the Current Spindle Speed

- Step 5: Adjust the Spindle Speed

- Step 6: Test the Spindle Speed

- Step 7: Monitor the Spindle Speed

- Step 8: Maintain the Spindle Speed

- Step 9: Benefits of Changing Spindle Speeds

- Step 10: Conclusion – Spindle Speeds Vs Benefits

- Frequently Asked Questions

Paragraph 1:

If you’re just getting started with CNC lathe work, you might find yourself a little overwhelmed by all the different settings you need to master. One of the most important of these is spindle speed. The spindle speed of your lathe will determine how quickly the material spins, which in turn affects the quality of your cuts. Understanding how to adjust spindle speed is essential for getting the results you want from your CNC lathe.

Paragraph 2:

Fortunately, changing spindle speeds on a CNC lathe is not as difficult as it might seem. However, there are a few key steps you need to follow to ensure you’re doing it correctly. In this article, we’ll take you through the process step-by-step, so you can feel confident that you’re making the right adjustments to your lathe. Whether you’re a beginner or an experienced machinist, this guide will help you get the most out of your CNC lathe.

- Refer to the machine manual to locate the spindle speed control panel.

- Press the spindle speed button to activate the control panel.

- Select the desired spindle speed using the arrow buttons or numerical keypad.

- Press enter to confirm the selected speed.

- Wait for the spindle to reach the desired speed before starting the machining process.

How to Change Spindle Speeds in CNC Lathe?

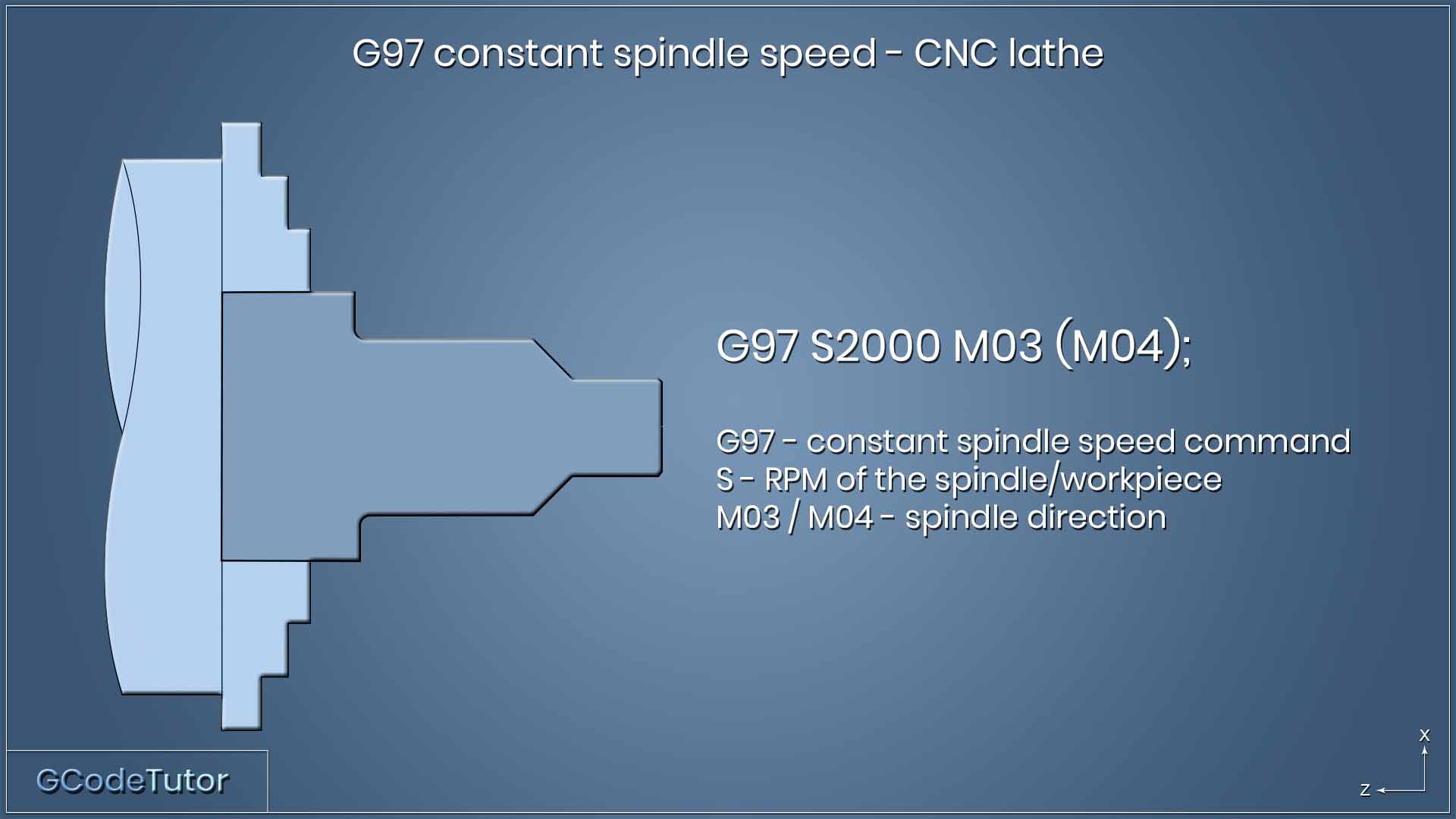

CNC lathes are popular in machining industries because of their ability to produce high-precision parts. One of the critical features of a CNC lathe is the spindle speed, which determines the cutting speed of the workpiece. In this article, we’ll discuss how to change spindle speeds in a CNC lathe, step by step.

Step 1: Understand the Spindle Speed Range

Before changing the spindle speed, it’s important to understand the range of speeds that your CNC lathe can handle. Most CNC lathes have a spindle speed range of 50 RPM to 5000 RPM. This range varies depending on the type and model of the lathe. You can find the spindle speed range in the machine manual or on the manufacturer’s website.

Once you know the spindle speed range, you can determine the optimal speed for the material you’re working with. For example, if you’re cutting aluminum, you might need a faster spindle speed than if you’re cutting steel.

Step 2: Select the Tool and Material

The next step is to select the tool and material you’ll be working with. Different materials require different cutting speeds, and the tool you use will also affect the spindle speed. For example, a smaller tool might require a higher spindle speed than a larger tool.

Once you’ve selected the tool and material, you can consult the cutting speed chart to determine the optimal spindle speed. The cutting speed chart is typically included in the machine manual or can be found online.

Step 3: Access the Spindle Speed Control

To change the spindle speed, you’ll need to access the spindle speed control on your CNC lathe. This is typically located on the control panel or on the machine itself.

Once you’ve located the spindle speed control, you can use the arrow keys to adjust the speed. Some CNC lathes also have a dial that you can turn to adjust the speed.

Step 4: Check the Current Spindle Speed

Before changing the spindle speed, it’s important to check the current speed to ensure that you’re making the correct adjustment. You can check the current spindle speed on the machine display or on the control panel.

If the current speed is outside of the recommended range for the material you’re working with, you’ll need to adjust the speed accordingly.

Step 5: Adjust the Spindle Speed

Using the spindle speed control, adjust the speed to the recommended setting for the material and tool you’re working with. It’s important to make small adjustments and test the speed before making any large changes.

Once you’ve made the adjustment, you can check the spindle speed again to ensure that it’s within the recommended range.

Step 6: Test the Spindle Speed

Before starting the machining process, it’s important to test the spindle speed to ensure that it’s working correctly. You can do this by running a test cut and measuring the surface finish.

If the surface finish is not satisfactory, you may need to adjust the spindle speed further.

Step 7: Monitor the Spindle Speed

During the machining process, it’s important to monitor the spindle speed to ensure that it remains within the recommended range. If the spindle speed is too high or too low, it can result in poor surface finish or even damage to the tool or material.

Step 8: Maintain the Spindle Speed

To ensure that the spindle speed remains consistent, it’s important to maintain the machine properly. This includes regular cleaning and lubrication of the spindle, as well as checking for any signs of wear or damage.

If you notice any issues with the spindle, such as vibrations or unusual noises, it’s important to address them immediately to prevent further damage.

Step 9: Benefits of Changing Spindle Speeds

Changing the spindle speed can have several benefits, including:

– Improved surface finish

– Longer tool life

– Reduced machining time

– Lower energy consumption

By adjusting the spindle speed to the optimal setting for the material and tool, you can achieve better results and save time and energy.

Step 10: Conclusion – Spindle Speeds Vs Benefits

In conclusion, changing spindle speeds in a CNC lathe is a critical part of the machining process. By understanding the spindle speed range, selecting the tool and material, and making small adjustments, you can achieve better results and save time and energy.

The benefits of changing spindle speeds include improved surface finish, longer tool life, reduced machining time, and lower energy consumption. By maintaining the machine properly and monitoring the spindle speed during the machining process, you can ensure consistent performance and avoid any issues that may arise.

Frequently Asked Questions

What is a CNC Lathe?

A CNC Lathe is a type of computer-controlled machine tool used in manufacturing. It is used to cut, drill, and shape materials such as metal, wood, and plastic. The CNC Lathe is operated by a computer program that controls the movement and position of the cutting tool.

Why is it important to change spindle speeds in a CNC Lathe?

The spindle speed is the rotational speed of the cutting tool. Changing the spindle speed is important because it affects the quality of the finished product. Different materials require different spindle speeds to achieve the best results. For example, a high spindle speed is needed to cut through steel, while a lower spindle speed is required for softer materials like wood.

How do you change spindle speeds in a CNC Lathe?

To change spindle speeds in a CNC Lathe, you need to adjust the settings on the machine. First, you need to select the appropriate cutting tool for the job. Then, you need to adjust the spindle speed to the appropriate setting for the material being cut. This can be done through the machine’s control panel or through the computer program that is controlling the machine.

What are the benefits of changing spindle speeds in a CNC Lathe?

Changing spindle speeds in a CNC Lathe has several benefits. First, it allows for more precise cutting and shaping of materials. Different materials require different speeds to achieve optimal results, and adjusting the spindle speed ensures that the finished product is of high quality. Additionally, changing spindle speeds can help extend the life of the cutting tool by reducing wear and tear.

What are some common mistakes to avoid when changing spindle speeds in a CNC Lathe?

One common mistake to avoid when changing spindle speeds in a CNC Lathe is using the wrong cutting tool for the job. Another mistake is not adjusting the spindle speed to the appropriate setting for the material being cut. It is also important to make sure that the cutting tool is properly secured in the machine and that the machine is properly calibrated before making any adjustments to the spindle speed.

In conclusion, changing spindle speeds in a CNC lathe is a crucial skill that every operator must possess. Whether you’re a seasoned professional or a beginner, understanding how to adjust spindle speeds is essential for producing high-quality workpieces.

By following the steps outlined above, you can easily change spindle speeds on your CNC lathe. Remember to always refer to your machine’s manual for specific instructions and to take proper safety precautions when operating the machine.

In the end, mastering the art of spindle speed adjustments in a CNC lathe takes practice, patience, and a willingness to learn. But with the right tools, knowledge, and experience, you can become a skilled operator and produce exceptional results.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com