CNC programming is an essential aspect of modern manufacturing, and it has revolutionized the way that products are made. It involves using computer numerical control (CNC) machines to automate the production process, resulting in more precise and efficient manufacturing.

At its core, CNC programming involves writing instructions that tell CNC machines how to perform specific tasks. These machines can cut, drill, and shape materials with incredible accuracy, allowing for the creation of products that would be impossible to make by hand. If you’re interested in learning more about CNC programming and how it’s used in manufacturing, read on to discover the basics of this fascinating field.

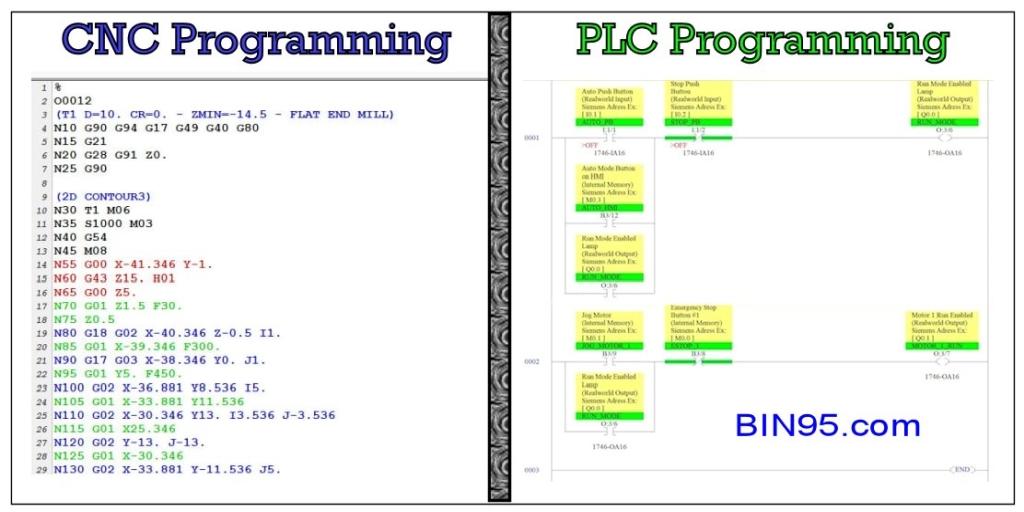

CNC programming is the process of creating a set of instructions that tell a computer-controlled machine how to make a part. CNC stands for Computer Numerical Control, and the programming language used to control these machines is called G-code. The G-code tells the machine where to move, how fast to move, and what actions to take, such as cutting or drilling. CNC programming is essential in modern manufacturing, allowing for high precision and efficiency in the production of parts.

Understanding CNC Programming: A Beginner’s Guide

CNC programming is an essential aspect of the manufacturing industry. It is a process that involves the use of computer software to control machines that cut and shape materials into specific shapes and sizes. CNC programming is critical in the production of various components, including automotive parts, aircraft components, medical devices, and many others. In this article, we will take a closer look at what CNC programming is and how it works.

What is CNC Programming?

CNC programming is the process of creating instructions that control the operation of CNC machines. These instructions are known as G-code, a standardized programming language used to tell the CNC machine what to do. CNC programming involves the use of computer-aided design (CAD) software to create a design or model of the component that needs to be produced. The software then generates the G-code that the CNC machine uses to cut and shape the material.

Creating CNC programs requires a deep understanding of the CNC machine, the material being used, and the cutting tools. The programmer must also have knowledge of the software used to create the design and generate the G-code. CNC programming is a highly specialized skill that requires years of training and experience to master.

The Components of CNC Programming

CNC programming consists of several components that work together to create the final product. These components include the machine, the cutting tools, the material, and the software. The CNC machine is the physical device that performs the cutting and shaping of the material. The cutting tools are the blades or bits that are used to remove material from the workpiece. The material being cut can vary depending on the application and can include metals, plastics, and composites.

The software used in CNC programming is critical in creating the G-code that controls the CNC machine. The software takes the design created in CAD software and generates the G-code that the CNC machine uses to cut and shape the material. The software also allows the programmer to simulate the cutting process to ensure that the final product meets the desired specifications.

The Benefits of CNC Programming

CNC programming offers several benefits over traditional manufacturing methods. One of the main benefits is increased accuracy and consistency. CNC machines can cut and shape materials with a level of precision that is impossible with manual methods. This results in components that are highly accurate and consistent, which is essential in industries such as aerospace and medical device manufacturing.

CNC programming also offers increased efficiency and productivity. Once the CNC program is created, the machine can run continuously without the need for human intervention. This allows for faster production times and increased output. CNC programming also allows for complex shapes and designs to be produced quickly and accurately, which would be impossible with manual methods.

CNC Programming vs. Traditional Manufacturing

CNC programming offers several advantages over traditional manufacturing methods. Traditional manufacturing methods typically involve manual labor and require skilled workers to perform the cutting and shaping of materials. This can be time-consuming and costly. CNC programming, on the other hand, allows for automation of the cutting process, which reduces the need for manual labor and increases efficiency.

CNC programming also offers increased accuracy and consistency compared to traditional manufacturing methods. Traditional methods rely on the skill and experience of the worker to produce accurate components. CNC programming eliminates this variability, resulting in components that are highly accurate and consistent.

Conclusion

CNC programming is an essential aspect of modern manufacturing. It allows for the automation of the cutting process, resulting in increased efficiency and productivity. CNC programming also offers increased accuracy and consistency, which is critical in industries such as aerospace and medical device manufacturing. While CNC programming requires specialized skills and training, its benefits make it a valuable tool in the manufacturing industry.

Frequently Asked Questions

What is CNC Programming?

CNC Programming is the process of creating sets of instructions that control the movement and operation of CNC machines. CNC, or Computer Numerical Control, machines are automated tools that are programmed to perform specific tasks. CNC programming involves creating a set of instructions, or code, that tells the machine what actions to perform, such as moving the cutting tool, adjusting the cutting depth, or turning on and off various components of the machine.

CNC programming is a vital part of the manufacturing process, as it allows for precise and accurate control of CNC machines. With CNC programming, manufacturers can create complex parts and components with a high level of accuracy, consistency, and efficiency.

What are the benefits of CNC Programming?

CNC programming offers a number of benefits for manufacturers and businesses. First and foremost, CNC programming allows for precise and accurate control of machines, which can lead to higher quality parts and components. CNC machines can also operate at faster speeds than manual machines, which can increase productivity and efficiency.

In addition, CNC programming can help reduce the risk of errors and mistakes, as the machines are programmed to perform specific tasks with a high level of accuracy. This can lead to a reduction in waste, as well as lower costs for materials and labor.

What are the different types of CNC Programming?

There are several different types of CNC programming, each of which is designed for specific types of machines and applications. Some of the most common types of CNC programming include turning, milling, drilling, and routing.

Turning CNC programming is used for lathes and other machines that rotate a workpiece. Milling CNC programming is used for machines that move a cutting tool across a workpiece. Drilling CNC programming is used for machines that drill holes in a workpiece. Routing CNC programming is used for machines that cut and shape materials using a rotating cutting tool.

What skills are required for CNC Programming?

CNC programming requires a number of skills and knowledge, including a strong understanding of mathematics and geometry, as well as knowledge of computer programming languages like G-code and M-code. In addition, CNC programmers must have the ability to read and interpret technical drawings and blueprints, as well as an understanding of materials and manufacturing processes.

Other important skills for CNC programming include attention to detail, problem-solving skills, and the ability to work well under pressure. CNC programmers must also have good communication skills, as they often work closely with engineers, machinists, and other professionals.

How can I learn CNC Programming?

There are several ways to learn CNC programming, including attending vocational schools or technical colleges, taking online courses or tutorials, or learning on the job through an apprenticeship or internship. Some manufacturers also offer training programs for CNC programming.

To become a skilled CNC programmer, it is important to have a strong foundation in mathematics and computer programming, as well as practical experience with CNC machines and manufacturing processes. It is also important to stay up-to-date with the latest technologies and advancements in the field.

In conclusion, CNC programming is an essential process used in modern manufacturing. It involves the use of computer software to control machines that produce high-precision parts and components. With CNC programming, companies can produce parts in large quantities with little to no errors, which ultimately saves time and money.

Moreover, CNC programming is becoming increasingly popular, and it is projected to continue growing in the coming years. As the demand for more complex parts and components increases, so does the need for highly skilled CNC programmers. This presents an excellent opportunity for those interested in a career in manufacturing.

In summary, CNC programming is a critical technology that has revolutionized the manufacturing industry. Its precision, speed, and efficiency make it an invaluable tool for producing high-quality parts and components. As technology continues to advance, CNC programming will undoubtedly become even more critical in shaping the future of manufacturing.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com