If you’ve ever worked with a CNC machine, you may have come across the term “homing switches” before. But what exactly are they? Homing switches are an essential component of any CNC machine and play a critical role in ensuring accuracy and precision during the machining process.

Put simply, homing switches are sensors that tell the CNC machine where its starting point is. Without homing switches, the machine would not know where to begin, and accuracy would suffer. In this article, we’ll explore the different types of homing switches, how they work, and why they are so crucial to the CNC machining process. So buckle up and get ready to learn all about homing switches!

Homing switches are sensors located at the end of each axis on a CNC machine. They enable the machine to locate its starting position accurately. When the machine initializes, it moves towards the switches until they are triggered. This signals the machine that it has reached its reference point, and it can then proceed with its programmed tasks. Homing switches are essential for precision and accuracy in CNC machining.

Understanding Homing Switches on a CNC Machine

What are Homing Switches?

Homing switches are an essential part of a CNC machine, which helps in determining the machine’s position accurately. They are a combination of sensors and switches that are placed on the machine’s axes, such as X, Y, and Z, and are responsible for measuring the machine’s movement in each direction. Homing switches help in establishing a reference point for the machine to start its operations from, and they also help in ensuring precise and accurate cuts.

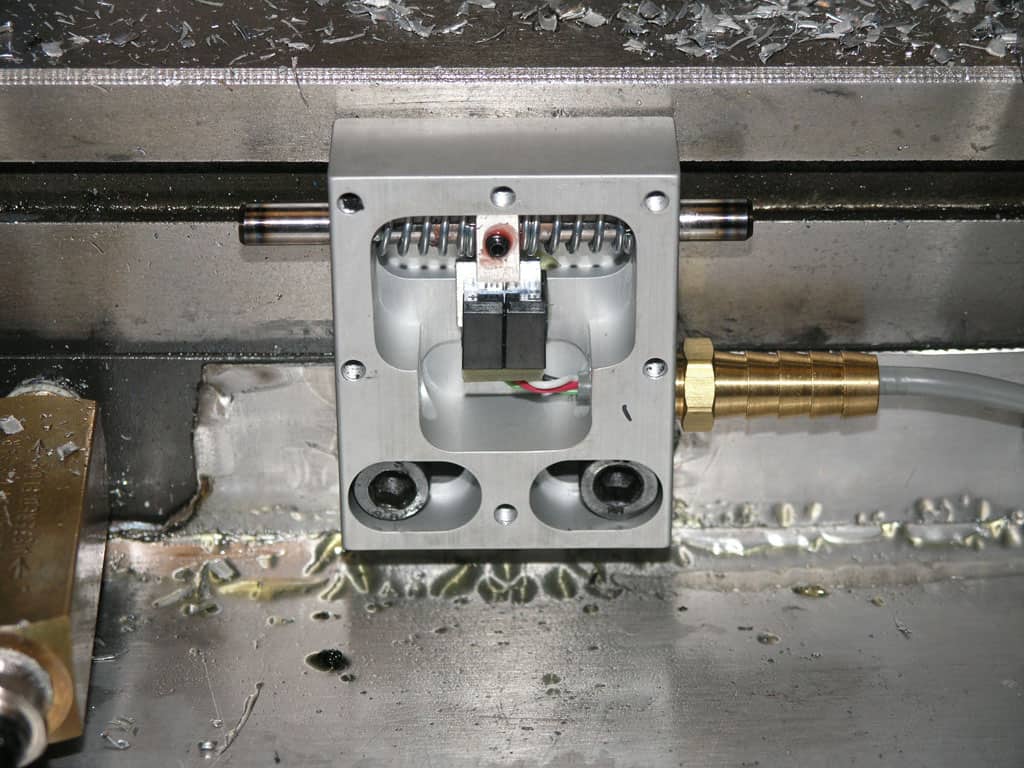

Homing switches typically comprise a sensor and a switch that are placed at specific locations on the machine’s axes. The sensor detects the machine’s position, and the switch sends a signal to the machine’s controller, indicating that the machine has reached its reference point.

How do Homing Switches Work?

When a CNC machine is powered on, the controller initializes the homing process. The machine moves along each of its axes until it reaches the homing switch. Once the switch is triggered, the machine stops, and the controller records the machine’s position at that point. The controller then knows the machine’s exact position and can use this information to execute precise and accurate movements.

Homing switches can also be used to detect if the machine has moved out of position during an operation. If the machine moves out of position, the homing switch can be used to bring the machine back to its reference point and start the operation again from there.

Benefits of Homing Switches

The use of homing switches offers several benefits to CNC machine operators. Here are some of the benefits of using homing switches on a CNC machine:

- Ensures accurate and precise cuts

- Helps in detecting if the machine has moved out of position during an operation

- Reduces the risk of crashes and collisions

- Increases the machine’s overall efficiency and productivity

- Helps in reducing the setup time for the machine

Homing Switches vs. Limit Switches

Homing switches are often confused with limit switches, but they serve different purposes. While homing switches are used to establish a reference point for the machine, limit switches are used to prevent the machine from moving beyond its physical limits.

Limit switches are usually placed at the end of each axis and are used to prevent the machine from overrunning its limits, which could result in damage to the machine or the workpiece being machined. Homing switches, on the other hand, are used to establish the machine’s starting position and are not used for preventing overruns.

Conclusion

Homing switches are a crucial component of a CNC machine, and they play a significant role in ensuring the machine’s accuracy and precision. They help in establishing a reference point for the machine, reducing the risk of crashes and collisions, and increasing the machine’s overall efficiency and productivity. It is essential to understand the difference between homing switches and limit switches to use them effectively on a CNC machine.

Frequently Asked Questions

Here are some of the most common questions people ask about homing switches on a CNC machine.

What are homing switches on a CNC machine?

Homing switches are sensors that tell the CNC machine where the origin or zero point is in each axis. When the machine is turned on, it moves each axis until it hits the homing switch, which then tells the machine that it has reached the zero point. This is important because it allows the machine to know where it is in space, and to accurately move to the correct position for each cut or operation.

Homing switches are usually located at the end of each axis, and are activated when the machine makes contact with them. They are usually made of metal and have a small button or lever that is pushed when the machine hits it. Some machines may have additional homing switches to provide redundancy, or to allow the machine to check its position during a job.

Why are homing switches important on a CNC machine?

Homing switches are important because they allow the machine to accurately locate the zero point for each axis. This is critical for ensuring that each cut or operation is performed correctly, and that the machine doesn’t accidentally move out of position. Without homing switches, the machine would have to rely on manual measurements to determine its position, which would be time-consuming and prone to error.

In addition to providing accurate positioning, homing switches also provide a safety feature. If the machine loses power or is otherwise interrupted during a job, it can use the homing switches to return to its zero point and avoid crashing into the material or damaging the machine.

How do I set up homing switches on a CNC machine?

The process for setting up homing switches will vary depending on the specific machine and controller that you are using. However, in general, you will need to connect the homing switches to the controller board, and then configure the controller to recognize them. This may involve setting up the switch type (normally open or normally closed), the location of the switches, and the direction of movement for each axis.

Once the switches are connected and configured, you will need to physically position the machine so that each axis is aligned with the corresponding homing switch. This is often done manually, by moving the machine into position and then triggering the switch. Once all of the switches have been triggered, the machine will be homed and ready for use.

Can I use limit switches instead of homing switches on a CNC machine?

While limit switches can serve a similar purpose to homing switches, they are not interchangeable. Limit switches are designed to stop the machine if it moves too far in a particular direction, whereas homing switches are used to locate the zero point for each axis.

In some cases, a machine may have both limit switches and homing switches. The limit switches provide a safety feature by preventing the machine from moving too far, while the homing switches allow the machine to accurately locate its position.

What happens if a homing switch fails on a CNC machine?

If a homing switch fails, the machine may not be able to accurately locate its zero point for that axis. This can cause errors in the positioning of cuts or operations, and may result in the machine crashing into the material or otherwise malfunctioning.

To prevent this, it is important to regularly check the homing switches for proper operation, and to replace them if they are damaged or not functioning correctly. Some machines may have redundant homing switches to provide a backup in case of a failure, but it is still important to keep them in good working order to ensure accurate and safe operation of the machine.

In conclusion, homing switches are an essential component of a CNC machine. They serve as a reference point for the machine’s position and help ensure accuracy and precision in the manufacturing process. Without homing switches, the machine would not be able to determine its exact location, leading to potential errors and mistakes in the final product.

Furthermore, homing switches also aid in the safety of the operator and the machine itself. By providing a home position, the machine can avoid collisions and prevent damage or injury. It is crucial to ensure that the homing switches are properly installed and calibrated to ensure maximum efficiency and safety.

In summary, homing switches are a vital part of a CNC machine that enables accurate positioning, precision, and safety. It is essential to understand the importance of homing switches and ensure they are functioning correctly to produce high-quality products efficiently.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com