Table of Contents

- Can You Cut Wood in a Fadal CNC Router?

- Frequently Asked Questions

- Can you cut wood in a Fadal CNC router?

- What type of wood can you cut in a Fadal CNC router?

- What router bit should you use to cut wood in a Fadal CNC router?

- What feed rate and cutting speed should you use to cut wood in a Fadal CNC router?

- What safety precautions should you take when cutting wood in a Fadal CNC router?

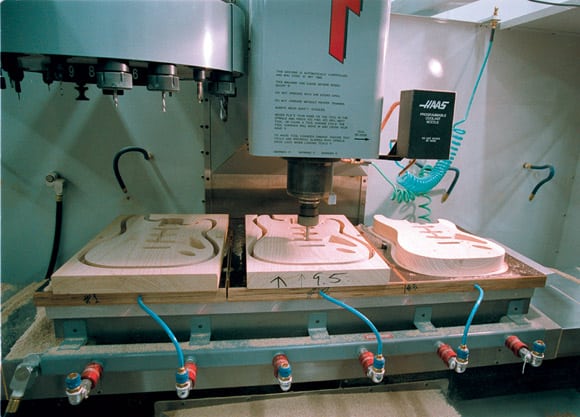

Are you wondering if it’s possible to cut wood in a Fadal CNC router? The answer is a resounding yes! Fadal CNC routers are versatile machines that can cut a variety of materials, including wood, plastic, and metal. With their precision and accuracy, Fadal CNC routers are an excellent choice for woodworkers who need to create intricate designs and shapes.

Whether you’re a hobbyist or a professional woodworker, a Fadal CNC router can help you take your woodworking projects to the next level. With its advanced technology and user-friendly interface, you can easily program the router to cut wood in any shape or size you need. So, if you’re looking to add a new dimension to your woodworking projects, consider investing in a Fadal CNC router and see the difference it can make!

Can You Cut Wood in a Fadal CNC Router?

When it comes to cutting wood, CNC routers are one of the most popular options in the market. But, can you cut wood in a Fadal CNC router? The short answer is yes, you can. In fact, Fadal CNC routers are known for their precision and accuracy, making them an excellent choice for woodworking projects of all sizes. However, there are a few things you should consider before you start cutting wood on your Fadal CNC router.

Understanding Fadal CNC Routers

Fadal CNC routers are designed to cut a variety of materials, including wood, plastic, and metal. These routers use computer numerical control (CNC) technology to control the cutting process, ensuring accuracy and precision with every cut. Fadal CNC routers are known for their reliability, and they are often used in industrial settings where precision and speed are critical.

When it comes to cutting wood on a Fadal CNC router, there are a few things to keep in mind. First, you will need to choose the right bit for your project. Woodworking bits come in a variety of shapes and sizes, and the bit you choose will depend on the type of wood you are cutting and the design of your project.

It is also essential to understand the limitations of your Fadal CNC router. While these routers are known for their precision and accuracy, they are not designed to cut through thick pieces of wood. If you need to cut thicker pieces of wood, you may need to use a different tool or consider outsourcing the cutting process to a professional woodworker.

The Benefits of Cutting Wood on a Fadal CNC Router

There are several benefits to cutting wood on a Fadal CNC router. First, these routers are incredibly precise, which means you can create intricate designs and patterns with ease. Second, Fadal CNC routers are incredibly efficient, which means you can complete projects quickly and with minimal waste. Third, these routers are easy to use, which means you don’t need to be an expert woodworker to get started.

Another benefit of using a Fadal CNC router for woodworking projects is that it allows you to automate your cutting process. This can save you a lot of time and money in the long run, as you won’t need to spend hours cutting wood by hand. Additionally, Fadal CNC routers are incredibly versatile, which means you can use them for a variety of woodworking projects, from simple home decor items to complex furniture pieces.

The Drawbacks of Cutting Wood on a Fadal CNC Router

While there are several benefits to cutting wood on a Fadal CNC router, there are also some drawbacks to keep in mind. First, these routers can be expensive, which means they may not be the best option for hobbyist woodworkers or those on a tight budget. Additionally, Fadal CNC routers require regular maintenance to ensure they are functioning correctly, which can add to the overall cost of owning one.

Another drawback of using a Fadal CNC router for woodworking projects is that it can be difficult to learn how to use the machine properly. If you are new to woodworking or CNC technology, it may take some time to get the hang of using a Fadal CNC router. Finally, as mentioned earlier, Fadal CNC routers are not designed to cut through thick pieces of wood, which can limit the scope of your woodworking projects.

Cutting Wood on a Fadal CNC Router vs. Other Tools

When it comes to cutting wood, there are several tools you can use, including circular saws, jigsaws, and band saws. So, how does cutting wood on a Fadal CNC router compare to using these other tools?

Compared to circular saws and jigsaws, Fadal CNC routers are much more precise and can create intricate designs and patterns with ease. Additionally, Fadal CNC routers are much more efficient than circular saws and jigsaws, which means you can complete projects more quickly and with less waste.

Compared to band saws, Fadal CNC routers are not as good at cutting through thick pieces of wood. However, Fadal CNC routers are much more precise and efficient than band saws, which can make them a better option for smaller woodworking projects.

Conclusion

In conclusion, cutting wood on a Fadal CNC router is an excellent option for woodworking projects of all sizes. These routers are incredibly precise, efficient, and versatile, making them a popular choice in the woodworking industry. While there are some drawbacks to using a Fadal CNC router for woodworking projects, the benefits outweigh the costs for many woodworkers. If you are looking for a reliable and efficient tool for your woodworking projects, a Fadal CNC router may be the perfect option for you.

Frequently Asked Questions

Here are the answers to some of the most common questions about cutting wood in a Fadal CNC router.

Can you cut wood in a Fadal CNC router?

Yes, you can definitely cut wood in a Fadal CNC router. In fact, Fadal routers are known for their versatility and can be used to cut a wide range of materials, including wood, plastic, and metal. However, it’s important to note that the type of wood you’re cutting and the specific router bit you’re using will affect the quality of the cut and the overall performance of the router.

When cutting wood with a Fadal router, it’s important to use the appropriate router bit for the job. For example, a spiral upcut bit is great for cutting through thicker pieces of wood, while a straight bit is better for more detailed cuts. Additionally, you’ll want to make sure that your router is properly calibrated and that you’re using the correct feed rate and cutting speed for the type of wood you’re working with.

What type of wood can you cut in a Fadal CNC router?

You can cut a wide range of wood types in a Fadal CNC router, including hardwoods, softwoods, and engineered wood products. However, the type of wood you’re cutting will affect the quality of the cut and the overall performance of the router. For example, hardwoods like oak and maple are generally more difficult to cut than softer woods like pine or cedar.

When choosing a wood type to cut in your Fadal router, it’s important to consider the thickness and density of the wood, as well as the specific application you’ll be using it for. For example, if you’re cutting wood for furniture or cabinetry, you’ll likely want to use a hardwood like oak or maple. On the other hand, if you’re cutting wood for a decorative sign or other craft project, a softer wood like pine or cedar may be more appropriate.

What router bit should you use to cut wood in a Fadal CNC router?

The type of router bit you should use to cut wood in a Fadal CNC router will depend on the specific application you’re working on. However, some common router bits for cutting wood include spiral upcut bits, straight bits, and V-groove bits.

A spiral upcut bit is great for cutting through thicker pieces of wood, as it helps to remove material more efficiently and reduces the risk of burning or chipping. Straight bits, on the other hand, are better for more detailed cuts, as they allow for greater precision and control. V-groove bits are ideal for creating decorative grooves or channels in wood, and can be used to add texture and depth to your projects.

What feed rate and cutting speed should you use to cut wood in a Fadal CNC router?

The feed rate and cutting speed you should use to cut wood in a Fadal CNC router will depend on the specific type of wood you’re cutting and the router bit you’re using. Generally speaking, you’ll want to use a slower feed rate and cutting speed when working with harder, denser woods, and a faster feed rate and cutting speed when working with softer woods or thinner materials.

It’s important to note that using the wrong feed rate or cutting speed can result in poor quality cuts, burning or chipping of the wood, and damage to your router bit or machine. Make sure to consult the manufacturer’s recommendations and adjust your settings accordingly to ensure the best possible results.

What safety precautions should you take when cutting wood in a Fadal CNC router?

When cutting wood in a Fadal CNC router, it’s important to take a number of safety precautions to protect yourself and your machine. First and foremost, always wear appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and a dust mask.

You should also make sure that your router is properly calibrated and that you’re using the correct router bit, feed rate, and cutting speed for the specific type of wood you’re working with. Additionally, be sure to properly secure your workpiece to the router table and use adequate clamping pressure to prevent movement or shifting during cutting.

In conclusion, while it is technically possible to cut wood on a Fadal CNC router, there are certain limitations and considerations to keep in mind.

Firstly, the type and quality of wood being used can greatly impact the results of the cut. Softer woods like pine or cedar may be easier to work with, while harder woods like oak or maple may require more specialized equipment or techniques.

Additionally, it is important to ensure that the router is properly set up and configured for wood cutting, with the appropriate tooling and cutting speeds selected. With the right approach and attention to detail, however, a Fadal CNC router can be a versatile and effective tool for woodworking projects.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com