Table of Contents

CNC routers are a versatile tool used in many industries, including woodworking, metalworking, and plastic fabrication. They are capable of creating precise cuts, intricate designs, and complex shapes with ease. However, to get the most out of a CNC router, it’s important to understand what file types it can use.

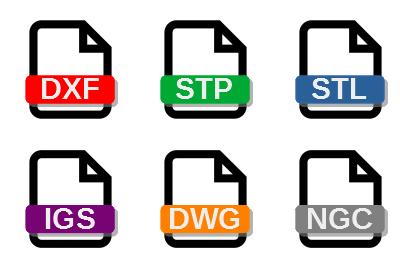

The most common file types used by CNC routers are G-code and DXF files. G-code is a programming language used to control the movements of the machine, while DXF files contain 2D and 3D designs. Understanding these file types can help you create and manipulate designs for your CNC router, unlocking its full potential.

What File Type Do CNC Routers Use?

CNC routers are computer-controlled machines that can cut and shape a variety of materials with precision and accuracy. They are widely used in manufacturing, woodworking, and other industries where precise cutting is required. However, to operate a CNC router, you need to provide it with the right type of file. In this article, we will explore the file types that CNC routers use.

1. G-code

G-code is the most commonly used file type for CNC routers. It is a programming language that tells the machine how to move and cut the material. G-code files are created using a CAM (Computer-Aided Manufacturing) software, which converts a 3D model into instructions that the machine can understand. G-code files can be edited manually or automatically, depending on the complexity of the design.

There are many benefits of using G-code files for CNC routers. First, they are easy to edit and modify, which allows you to make changes to the design without having to start from scratch. Second, G-code files are compatible with most CNC routers, which means you can use the same file for different machines. Finally, G-code files are highly accurate and precise, which ensures that your designs are cut exactly as you intended.

2. DXF

DXF (Drawing Exchange Format) is another file type that CNC routers can use. It is a vector-based file format that is widely used in the CAD (Computer-Aided Design) industry. DXF files are created using a CAD software, which allows you to create 2D and 3D designs that can be exported to a CNC router.

The main advantage of using DXF files for CNC routers is that they are highly customizable. You can create complex shapes and designs using a CAD software, and then export them to a DXF file for the CNC router to cut. DXF files are also compatible with most CNC routers, which means you can use the same file for different machines.

3. DWG

DWG (Drawing) is a file format that is used by AutoCAD, a popular CAD software. DWG files are similar to DXF files, but they are more complex and can contain more information. DWG files can be exported to a CNC router, but they require a special plugin or converter to do so.

The main advantage of using DWG files for CNC routers is that they are highly customizable and can contain a lot of information. However, they are not as widely used as G-code or DXF files and require additional software to convert them to a format that the CNC router can understand.

4. SVG

SVG (Scalable Vector Graphics) is a file format that is used for 2D graphics and animations. SVG files are created using a vector graphics editor, such as Adobe Illustrator or Inkscape. SVG files can be exported to a CNC router, but they require a special plugin or converter to do so.

The main advantage of using SVG files for CNC routers is that they are highly customizable and can contain a lot of information. However, they are not as widely used as G-code or DXF files and require additional software to convert them to a format that the CNC router can understand.

5. STL

STL (Standard Tessellation Language) is a file format that is used for 3D printing and CNC routing. STL files are created using a 3D modeling software, such as SketchUp or Blender. STL files can be exported to a CNC router, but they require a special plugin or converter to do so.

The main advantage of using STL files for CNC routers is that they can create complex 3D designs that other file types cannot. However, they are not as widely used as G-code or DXF files and require additional software to convert them to a format that the CNC router can understand.

6. BMP

BMP (Bitmap) is a file format that is used for digital images. BMP files can be imported into a CNC router software and used as a template for cutting. However, BMP files do not contain any cutting information, which means you will need to manually program the CNC router to cut the material.

The main advantage of using BMP files for CNC routers is that they are easy to create and can be used as a template for cutting. However, they are not as precise as other file types and require manual programming to cut the material.

7. NC

NC (Numerical Control) is a file format that is used for CNC machines. NC files contain a list of instructions that the CNC router can understand. NC files can be created using a text editor or a specialized CAM software.

The main advantage of using NC files for CNC routers is that they are highly customizable and can contain a lot of information. However, they are not as widely used as G-code or DXF files and require additional software to convert them to a format that the CNC router can understand.

8. HPGL

HPGL (Hewlett-Packard Graphics Language) is a file format that is used for technical drawings and diagrams. HPGL files can be imported into a CNC router software and used as a template for cutting. However, HPGL files do not contain any cutting information, which means you will need to manually program the CNC router to cut the material.

The main advantage of using HPGL files for CNC routers is that they are widely used in the technical industry and can be used as a template for cutting. However, they are not as precise as other file types and require manual programming to cut the material.

9. EPS

EPS (Encapsulated PostScript) is a file format that is used for vector graphics. EPS files can be imported into a CNC router software and used as a template for cutting. However, EPS files do not contain any cutting information, which means you will need to manually program the CNC router to cut the material.

The main advantage of using EPS files for CNC routers is that they are highly customizable and can contain a lot of information. However, they are not as precise as other file types and require manual programming to cut the material.

10. AI

AI (Adobe Illustrator) is a file format that is used for vector graphics. AI files can be imported into a CNC router software and used as a template for cutting. However, AI files do not contain any cutting information, which means you will need to manually program the CNC router to cut the material.

The main advantage of using AI files for CNC routers is that they are highly customizable and can contain a lot of information. However, they are not as precise as other file types and require manual programming to cut the material.

Conclusion

In conclusion, CNC routers can use a variety of file types, including G-code, DXF, DWG, SVG, STL, BMP, NC, HPGL, EPS, and AI. Each file type has its own advantages and disadvantages, and the choice depends on the complexity of the design and the CNC router software being used. By understanding the different file types, you can choose the one that best suits your needs and create precise and accurate designs with your CNC router.

Frequently Asked Questions

What file type do CNC routers use?

CNC routers use a specific file type that is compatible with their software. The most common file types used by CNC routers are G-code and DXF. G-code is a language used to control the CNC machine and tells it how to move, while DXF is a file format used to transfer 2D and 3D designs between software programs. Both file types can be created using CAD software and then converted into a format that is compatible with the CNC router’s software.

It is important to note that not all CNC routers use the same file type, so it is important to check with the manufacturer or software provider to determine the correct file type for your specific machine. Additionally, some CNC routers may also be able to use other file types such as STEP or STL, which are commonly used in 3D printing.

How do I convert my design into a file type compatible with a CNC router?

To convert a design into a file type compatible with a CNC router, you will need to use CAD software. This software allows you to create a 2D or 3D design and then export it into a file format that is compatible with the CNC router’s software.

The specific steps for exporting your design will vary depending on the CAD software you are using, but most programs will have an option to export your design as a G-code or DXF file. Once you have exported your design, you can then transfer it to the CNC router and begin the manufacturing process.

It is important to ensure that your design is properly formatted and optimized for the CNC router before exporting it. This will help to ensure that the machine can accurately and efficiently produce your design without errors or complications.

In conclusion, CNC routers have revolutionized the manufacturing industry by providing a high level of precision and accuracy in cutting. When it comes to file types, CNC routers support various formats such as G-code, DXF, and DWG. These file types are essential in providing precise instructions for the machine to follow during the cutting process.

It’s important to note that different CNC routers support different file types, and it’s crucial to ensure that the chosen file format is compatible with the specific machine. Using the right file type can significantly reduce the chances of errors and ensure that the finished product meets the required specifications.

In conclusion, with the right file type, CNC routers can create complex shapes and designs with ease, making them an essential tool in the manufacturing industry. Understanding the various file types and their compatibility with different CNC routers can help ensure a seamless and efficient cutting process.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com