Table of Contents

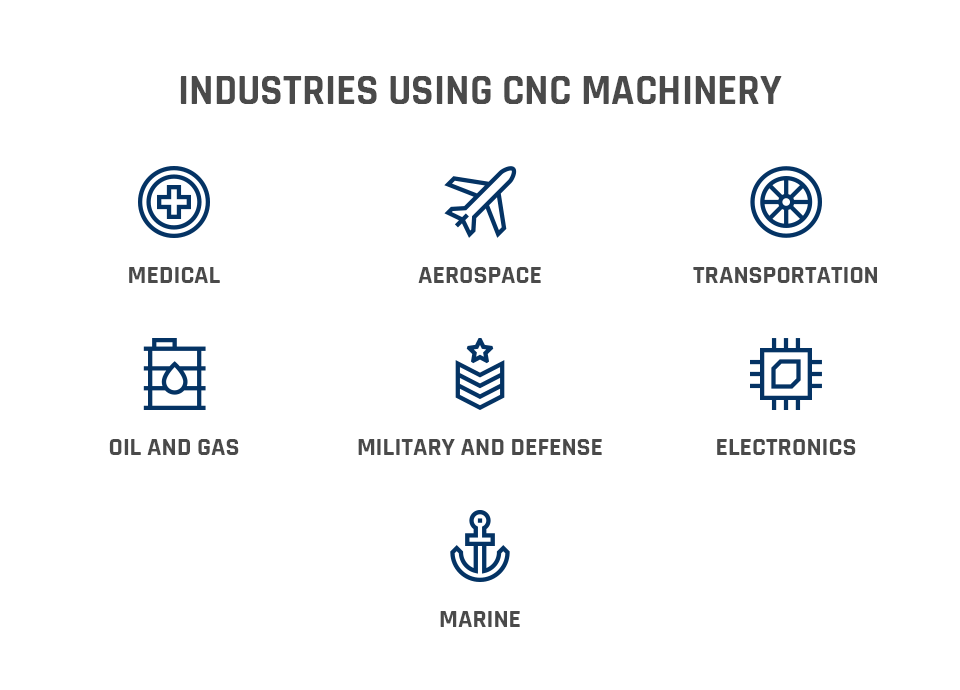

Computer Numerical Control (CNC) machines are becoming increasingly popular in various industries. These machines are used to automate manufacturing processes and have revolutionized the way products are made. From automobiles to aerospace, CNC machines are utilized in a wide range of industries to produce high-quality components with precision and accuracy.

In today’s fast-paced world, the use of CNC machines has become essential for industries that rely on high-volume production. The manufacturing industry, in particular, has seen a significant increase in the use of CNC machines due to their ability to produce complex parts with ease. In this article, we will explore some of the industries that use CNC machines and how they are changing the manufacturing landscape.

What Industries Use CNC Machines?

CNC (Computer Numerical Control) machines are a vital part of the modern manufacturing industry, revolutionizing the way products are made. CNC machines utilize computer software to operate and control machining tools, making the manufacturing process faster, more precise, and more efficient. In this article, we’ll take a closer look at the industries that use CNC machines and how they benefit from this technology.

Automotive Industry

The automotive industry was one of the earliest adopters of CNC technology, and it remains one of the largest users of CNC machines today. CNC machines are used to manufacture various components of a vehicle, such as engine parts, suspension components, and body panels. The precision and accuracy of CNC machines ensure that these parts are manufactured to exact specifications, leading to better performance and reliability.

In addition, CNC machines are capable of producing complex shapes that are difficult or impossible to make with traditional manufacturing methods. This capability has allowed designers to create innovative and aerodynamic body designs that were not possible before.

Aerospace Industry

The aerospace industry relies heavily on CNC machines to manufacture aircraft parts and components. CNC machines are used to produce various parts of an aircraft, such as turbine blades, engine mounts, and landing gear components. The aerospace industry demands high levels of precision and accuracy, and CNC machines meet these requirements.

CNC machines also allow for the creation of lightweight and complex parts that are essential in the aerospace industry. With CNC machines, designers can create parts that are optimized for weight and strength, leading to more fuel-efficient and cost-effective aircraft.

Medical Industry

The medical industry uses CNC machines to manufacture medical devices and implants. CNC machines are used to create various components of medical devices, such as surgical instruments, dental implants, and prosthetic limbs. The precision and accuracy of CNC machines ensure that these devices are safe and effective for patients.

CNC machines also allow for the creation of customized medical devices that are tailored to individual patients. With CNC machines, medical professionals can create implants and prosthetics that fit a patient’s unique anatomy, leading to better results and faster recovery times.

Electronics Industry

The electronics industry relies on CNC machines to manufacture various components of electronic devices, such as circuit boards, computer chips, and connectors. CNC machines are essential in the production of these components, as they require high levels of precision and accuracy.

CNC machines also allow for the creation of complex and miniaturized electronic components that are essential in the electronics industry. With CNC machines, manufacturers can create components that are smaller, faster, and more powerful than ever before.

Woodworking Industry

The woodworking industry uses CNC machines to manufacture various products, such as furniture, cabinetry, and decorative items. CNC machines are used to create precise cuts and shapes in wood, leading to better quality and consistency in the finished product.

CNC machines also allow for the creation of complex and intricate designs that were not possible before. With CNC machines, designers can create unique and intricate patterns that add value and beauty to their products.

Metalworking Industry

The metalworking industry uses CNC machines to manufacture various products, such as machine parts, tools, and industrial equipment. CNC machines are used to create precise cuts and shapes in metal, leading to better quality and consistency in the finished product.

CNC machines also allow for the creation of complex and intricate designs that were not possible before. With CNC machines, designers can create metal products that are both functional and aesthetically pleasing.

Plastics Industry

The plastics industry uses CNC machines to manufacture various products, such as packaging, toys, and automotive parts. CNC machines are used to create precise cuts and shapes in plastic, leading to better quality and consistency in the finished product.

CNC machines also allow for the creation of complex and intricate designs that were not possible before. With CNC machines, designers can create plastic products that are both functional and visually appealing.

Construction Industry

The construction industry uses CNC machines to manufacture various products, such as pre-fabricated building components, molds, and forms. CNC machines are used to create precise cuts and shapes in these components, leading to better quality and efficiency in the construction process.

CNC machines also allow for the creation of customized building components that are tailored to specific building designs. With CNC machines, designers can create unique and innovative building designs that were not possible before.

Jewelry Industry

The jewelry industry uses CNC machines to manufacture various products, such as rings, necklaces, and earrings. CNC machines are used to create precise cuts and shapes in precious metals, leading to better quality and consistency in the finished product.

CNC machines also allow for the creation of intricate and detailed designs that were not possible before. With CNC machines, designers can create unique and one-of-a-kind jewelry pieces that are both beautiful and valuable.

Food Industry

The food industry uses CNC machines to manufacture various products, such as molds and cutting tools. CNC machines are used to create precise cuts and shapes in food products, leading to better quality and consistency in the finished product.

CNC machines also allow for the creation of customized food products that are tailored to specific designs. With CNC machines, chefs and food manufacturers can create unique and innovative food designs that are both visually appealing and delicious.

In conclusion, CNC machines have revolutionized the way products are manufactured in various industries. With their precision and accuracy, CNC machines have made it possible to create complex and innovative designs that were not possible before. As technology continues to advance, the use of CNC machines will only become more widespread, leading to more efficient and cost-effective manufacturing processes.

Frequently Asked Questions

What is a CNC machine?

A CNC (Computer Numerical Control) machine is a type of manufacturing equipment that automates the production process. It uses computer software to control the movement and operation of machine tools, such as lathes, routers, mills, and grinders. CNC machines are capable of producing complex parts with high precision and accuracy.

CNC machines are widely used in industries such as aerospace, automotive, medical, and electronics. They are also used in small-scale manufacturing, such as prototyping and hobbyist projects.

What industries use CNC machines?

CNC machines are used in a wide range of industries, including aerospace, automotive, medical, electronics, and woodworking. In aerospace, CNC machines are used to manufacture complex parts for aircraft engines, wings, and fuselages. In the automotive industry, CNC machines are used to produce engine components, car bodies, and interior parts.

In the medical industry, CNC machines are used to manufacture surgical tools, implants, and prosthetics. In electronics, CNC machines are used to produce circuit boards and other electronic components. In woodworking, CNC machines are used to carve intricate designs and shapes into wood.

What are the benefits of using CNC machines?

CNC machines offer several benefits over traditional manufacturing methods. They are capable of producing parts with high precision and accuracy, which reduces the need for manual labor and improves product quality. CNC machines also allow for faster production times and increased efficiency, which can lead to cost savings and increased profitability.

CNC machines also offer greater flexibility and versatility, as they can be programmed to produce a wide range of parts and products. They also allow for greater consistency and repeatability, which is important in industries that require high-quality and reliable products.

What types of materials can be used with CNC machines?

CNC machines can be used with a wide range of materials, including metals, plastics, ceramics, and composites. In the aerospace industry, CNC machines are used to work with high-strength materials such as titanium and magnesium. In the automotive industry, CNC machines are used to work with steel and aluminum.

In the medical industry, CNC machines are used to work with biocompatible materials such as titanium and stainless steel. In electronics, CNC machines are used to work with plastics and composites. In woodworking, CNC machines are used to work with a variety of woods and other materials.

What skills are required to operate CNC machines?

Operating a CNC machine requires a combination of technical, mechanical, and programming skills. Operators must be able to read technical drawings and blueprints, as well as understand the programming language used to control the machine.

They must also be skilled in the operation of machine tools, such as lathes, mills, and grinders. In addition, they must be able to troubleshoot and diagnose problems with the machine, as well as perform routine maintenance and repairs. Training and certification programs are available to help individuals develop the necessary skills to operate CNC machines.

In conclusion, CNC machines have revolutionized the manufacturing industry by providing a more efficient and precise way of producing goods. From automotive to aerospace, the list of industries utilizing CNC machines is endless. The use of CNC machines has not only improved the quality of products but has also increased production rates, leading to cost-saving benefits.

The medical industry has also embraced the use of CNC machines for the manufacturing of medical equipment and implants. With the use of CNC machines, the medical industry can ensure precision and accuracy in the production of these critical components, leading to better patient outcomes.

In addition, the use of CNC machines in the jewelry industry has allowed for intricate and unique designs to be produced with ease. By using CAD software and CNC machines, jewelers can create complex designs that were previously impossible to make by hand. The use of CNC machines has not only improved the speed of production but has also opened up a world of possibilities in terms of design.

Overall, the versatility of CNC machines has made them a crucial asset to various industries. Their ability to produce high-quality products with precision and accuracy has made them an essential tool for modern-day manufacturing. As technology continues to advance, the use of CNC machines will only continue to grow and expand into new industries.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com