If you own a CNC machine, you know the importance of using the right router bits. But what if you have a collection of regular router bits lying around? Can you use them in your CNC machine? This is a common question among CNC enthusiasts, and the answer may surprise you. In this article, we’ll explore the differences between regular router bits and CNC router bits and determine if it’s possible to use regular router bits in a CNC machine. So, let’s get started!

Yes, you can use regular router bits in a CNC machine, but it’s not always recommended. CNC machines are designed to work with specialized bits that are optimized for speed, accuracy, and precision. Using regular router bits can result in poor quality cuts, broken bits, and damage to your machine. It’s best to use CNC-specific bits that are designed for your machine’s specifications to ensure optimal performance and longevity.

Can You Use Regular Router Bits in a CNC Machine?

Understanding CNC Machines and Router Bits

CNC machines are a popular choice for woodworkers, metalworkers, and other craftsmen who require precision and accuracy in their work. They use computer software to control the movement of the cutting tool, which makes it possible to produce intricate designs and shapes with ease.

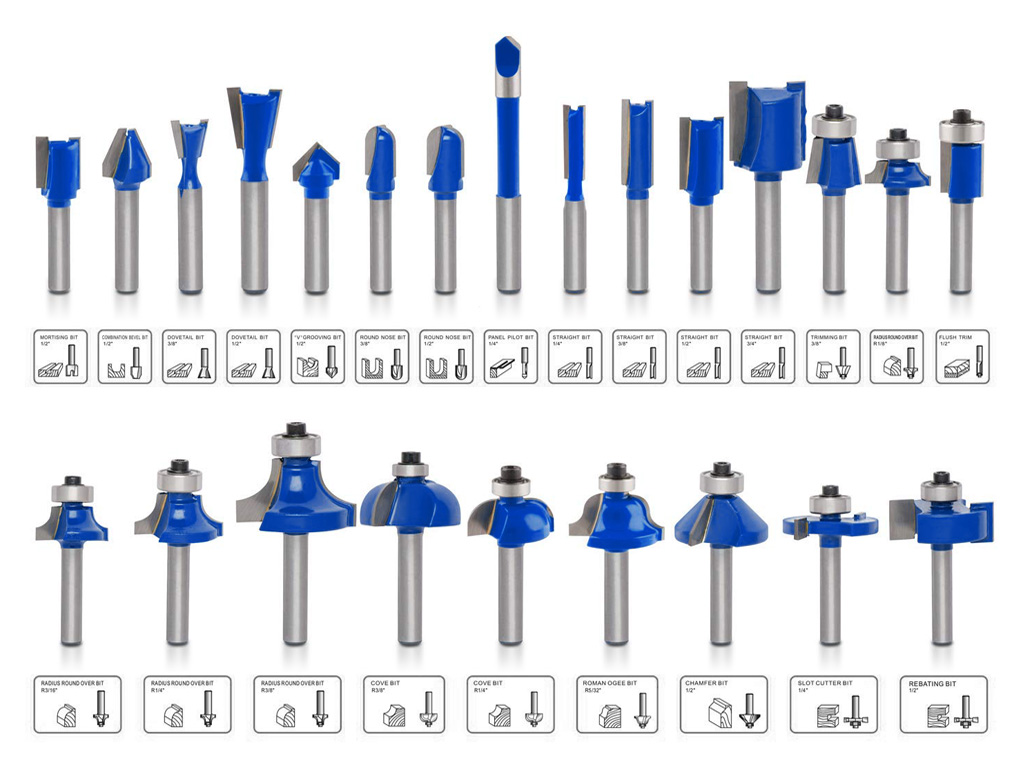

Router bits, on the other hand, are cutting tools that are designed to be used with a handheld or table-mounted router. They come in a variety of shapes and sizes, and are typically made from high-speed steel or carbide.

Compatibility of Router Bits with CNC Machines

Many woodworkers wonder if they can use regular router bits in their CNC machines. The short answer is yes, you can use regular router bits in a CNC machine, but there are some things you need to keep in mind.

First, you need to make sure that the router bit is compatible with the CNC machine’s collet size. Most CNC machines use 1/4-inch or 1/2-inch collets, so you should choose router bits that match these sizes.

Second, you need to consider the speed at which the CNC machine operates. CNC machines typically run at much higher speeds than handheld routers, so you need to choose router bits that are designed to handle these speeds.

Benefits of Using Regular Router Bits in a CNC Machine

One of the main benefits of using regular router bits in a CNC machine is cost savings. CNC-specific router bits can be expensive, so using regular router bits can be a more affordable option.

Additionally, using regular router bits can give you more flexibility in your work. Because there are so many different types of router bits available, you can choose the one that is best suited for your specific project.

Drawbacks of Using Regular Router Bits in a CNC Machine

While using regular router bits in a CNC machine can be beneficial in some ways, there are also some drawbacks to consider. For one, regular router bits may not be as durable as CNC-specific bits, which can result in more frequent replacement.

Additionally, regular router bits may not be able to handle the high speeds and precision that CNC machines are capable of, which can result in less accurate cuts and a lower quality finished product.

Conclusion

In summary, it is possible to use regular router bits in a CNC machine, but you need to be careful when selecting the right bit. You should choose a router bit that is compatible with your machine’s collet size and can handle the high speeds of the CNC machine.

While there are some benefits to using regular router bits, such as cost savings and flexibility, there are also some drawbacks, such as decreased durability and precision. Ultimately, the choice of whether to use regular router bits or CNC-specific bits will depend on your individual needs and preferences.

Frequently Asked Questions

Here are some of the frequently asked questions about using regular router bits in a CNC machine:

Can You Use Regular Router Bits in a CNC Machine?

Yes, you can use regular router bits in a CNC machine, but it is not always recommended. CNC machines use a different technology than traditional routers, and the bits used in each machine are designed differently. The bits used in a CNC machine are usually carbide tipped to withstand the high speeds and forces of the machine.

Regular router bits are not always designed to withstand the high speeds and forces generated by a CNC machine, and they can wear out quickly or even break. If you want to use regular router bits in a CNC machine, make sure to use a lower cutting speed and take shallow cuts to reduce the stress on the bit.

What Are the Differences Between Regular Router Bits and CNC Router Bits?

The main difference between regular router bits and CNC router bits is the design. CNC router bits are designed to withstand the high speeds and forces generated by CNC machines, and they are usually made of carbide to ensure durability.

Regular router bits, on the other hand, are designed for use with traditional routers, which operate at lower speeds and forces. They are often made of high-speed steel or other materials that are not as durable as carbide.

What Happens if You Use Regular Router Bits in a CNC Machine?

If you use regular router bits in a CNC machine, they may wear out quickly or even break. This is because regular router bits are not designed to withstand the high speeds and forces generated by a CNC machine. Additionally, using regular router bits in a CNC machine can result in poor quality cuts and a shorter lifespan for your machine.

If you want to use regular router bits in a CNC machine, make sure to use a lower cutting speed and take shallow cuts to reduce the stress on the bit. However, it is always recommended to use CNC-specific router bits for best results.

Are CNC Router Bits More Expensive Than Regular Router Bits?

Generally, CNC router bits are more expensive than regular router bits. This is because they are designed to withstand the high speeds and forces generated by a CNC machine, and they are usually made of carbide to ensure durability.

Regular router bits, on the other hand, are designed for use with traditional routers, which operate at lower speeds and forces. They are often made of high-speed steel or other materials that are not as durable as carbide. However, the cost of CNC router bits can vary depending on the type and quality of the bit.

What Are the Advantages of Using CNC Router Bits?

The main advantage of using CNC router bits is their durability. CNC router bits are designed to withstand the high speeds and forces generated by CNC machines, and they are usually made of carbide to ensure long-lasting performance.

CNC router bits also offer greater precision and accuracy than regular router bits, thanks to the advanced technology of CNC machines. Additionally, using CNC router bits can result in faster cutting speeds and reduced waste, making them a more efficient option for woodworking and other applications.

In conclusion, it is possible to use regular router bits in a CNC machine, but it is not recommended. CNC machines require specific types of bits to achieve accurate and precise cuts, and regular router bits may not be able to deliver the same level of precision.

Using regular router bits can also lead to damage to both the machine and the bit itself, as they may not be designed to withstand the high-speed and force of a CNC machine. This can result in costly repairs or replacements.

Investing in CNC-specific bits may seem like an added expense, but it is a worthwhile investment in the long run. They offer better performance, longer lifespan, and ultimately, better results. So, while it may be tempting to use regular router bits in a CNC machine, it is best to stick to the recommended tools for optimal results.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com