Circular interpolation is a crucial function in CNC machining that enables the creation of complex shapes and intricate designs. This powerful technique involves a coordinated movement of the cutting tool in a circular path, allowing for the production of smooth curves and arcs with unparalleled precision and accuracy.

Whether you are a seasoned CNC operator or a beginner looking to expand your knowledge, understanding the principles of circular interpolation is essential for achieving the highest level of precision and efficiency in your machining operations. In this article, we will explore the basics of circular interpolation and discuss how it can be used to create complex geometries with ease.

Understanding Circular Interpolation in CNC

Circular interpolation is a critical function in CNC that enables the machine to produce circular or arc-shaped cuts, drills, and holes in a workpiece. It involves the movement of the tool along a circular path, with the radius and center point programmed into the CNC system.

How Does Circular Interpolation Work?

Circular interpolation involves the use of G02 and G03 codes in the CNC program. G02 is used for clockwise circular motion, while G03 is used for counterclockwise motion. The CNC machine moves the tool along the programmed circular path, with the tool’s position, speed, and direction precisely controlled by the CNC system.

The radius and center point of the circle are determined by the X, Y, and Z coordinates programmed into the CNC program. The CNC machine calculates the tool’s movement based on the programmed coordinates and the tool’s current position, ensuring accurate and precise circular cuts.

Types of Circular Interpolation

There are two types of circular interpolation in CNC: full-circle and partial-circle interpolation.

Full-Circle Interpolation: In full-circle interpolation, the tool moves along a complete circle or arc. This type of interpolation is used for producing circular cuts or holes in a workpiece.

Partial-Circle Interpolation: In partial-circle interpolation, the tool moves along a segment of a circle or arc. This type of interpolation is used for producing partial circular cuts, such as fillets or chamfers.

Benefits of Circular Interpolation

Circular interpolation offers several benefits in CNC machining, including:

Precision: Circular interpolation enables precise and accurate circular cuts, with the radius and center point programmed into the CNC system.

Efficiency: Circular interpolation allows for the production of circular cuts and holes in a single pass, reducing machining time and increasing efficiency.

Flexibility: Circular interpolation can produce circular cuts of various sizes and shapes, making it a versatile machining process.

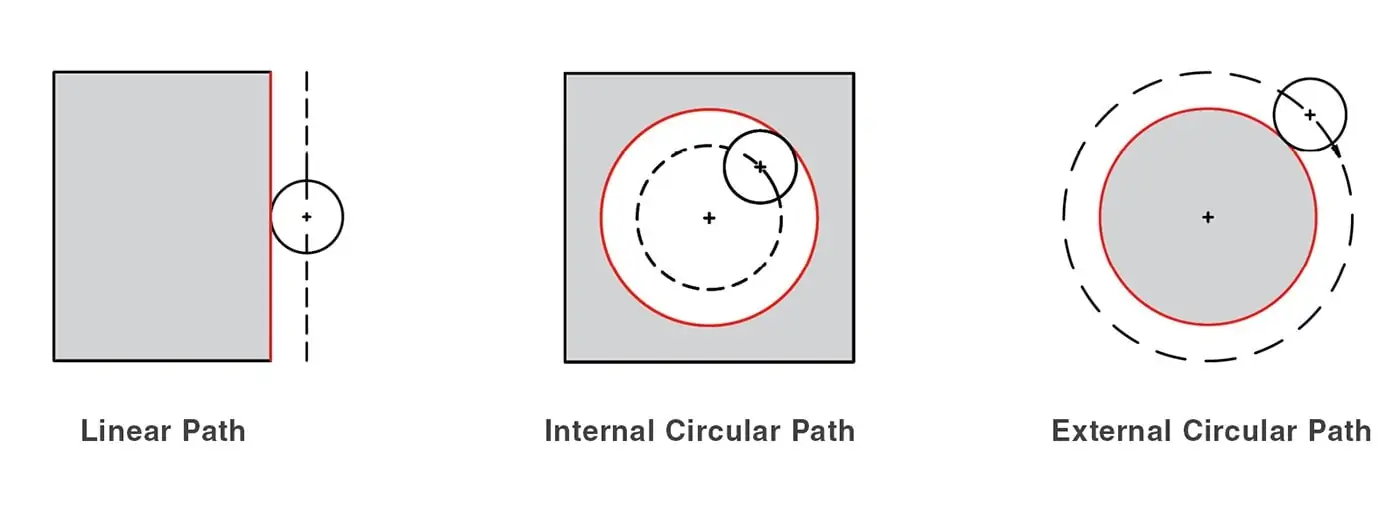

Circular Interpolation vs. Linear Interpolation

Linear interpolation involves the movement of the tool along a straight line, while circular interpolation involves the movement of the tool along a circular path. Linear interpolation is used for producing straight cuts or holes, while circular interpolation is used for producing circular or arc-shaped cuts or holes.

Circular interpolation offers more flexibility in terms of producing circular cuts of various sizes and shapes compared to linear interpolation. However, linear interpolation is faster and more efficient for producing straight cuts or holes.

Circular Interpolation Applications

Circular interpolation is commonly used in CNC machining for producing circular cuts, holes, and arcs in various workpieces, including:

Automotive Parts: Circular interpolation is used in the production of engine components, such as pistons and crankshafts.

Aerospace Parts: Circular interpolation is used in the production of aircraft components, such as turbine blades and engine casings.

Medical Devices: Circular interpolation is used in the production of medical implants, such as hip and knee replacements.

Circular Interpolation Challenges

Circular interpolation can pose some challenges in CNC machining, including:

Tool Deflection: Circular interpolation can cause the tool to deflect, resulting in inaccurate cuts or holes.

Material Hardness: Circular interpolation can cause excessive tool wear or breakage when machining hard materials.

Programming Errors: Incorrect programming of the CNC system can result in inaccurate cuts or holes, leading to scrap parts and increased machining time.

Circular Interpolation Best Practices

To overcome the challenges of circular interpolation in CNC machining, it is essential to follow best practices, including:

Tool Selection: Selecting the right tool for the job, including the correct tool geometry and material, can reduce tool deflection and wear.

Material Selection: Choosing the right material for the workpiece can reduce tool wear and breakage.

Programming: Ensuring accurate and precise programming of the CNC system can reduce errors and scrap parts.

Conclusion

Circular interpolation is a critical function in CNC machining that enables the production of circular cuts, holes, and arcs in various workpieces. Understanding the types, benefits, challenges, and best practices of circular interpolation can help ensure accurate and efficient CNC machining operations.

Frequently Asked Questions

Circular interpolation is a commonly used technique in CNC machining to create circular paths for cutting or drilling materials. This process involves the use of specialized software to program the machine to move in a circular motion, typically using a combination of X, Y, and Z-axis movements. Here are some frequently asked questions about circular interpolation in CNC:

What is circular interpolation in CNC?

Circular interpolation is a method of controlling the movement of a CNC machine to create circular paths for cutting or drilling materials. This process involves the use of specialized software to program the machine to move in a circular motion, typically using a combination of X, Y, and Z-axis movements. The software calculates the necessary movements and coordinates to achieve the desired circular path.

Circular interpolation is commonly used in CNC machining for creating curved surfaces or patterns in materials. It allows for precise control over the shape and size of the circles or curves being created, making it an essential technique for many applications.

What are the benefits of circular interpolation in CNC?

Circular interpolation in CNC machining offers several benefits. Firstly, it allows for precise control over the shape and size of the circles or curves being created, resulting in accurate and consistent cuts or drills. It also enables the production of complex curved shapes that would be difficult or impossible to create using other methods. Additionally, it can lead to faster production times and reduced waste, as the machine can cut or drill more efficiently and accurately.

Another benefit of circular interpolation is that it can be used with a variety of materials, including metals, plastics, and composites. This versatility makes it a useful technique for a wide range of industries, from aerospace and automotive to medical and electronics.

How is circular interpolation programmed in CNC?

Circular interpolation is programmed in CNC using specialized software that allows the user to specify the size and shape of the circular path. The software calculates the necessary movements and coordinates to achieve the desired circular path, using a combination of X, Y, and Z-axis movements. The user can adjust various parameters, such as the radius of the circle, the feed rate, and the number of revolutions, to achieve the desired result.

Once the program is complete, it is uploaded to the CNC machine, which executes the movements and cuts or drills the material according to the programmed circular path. The process can be repeated multiple times to create complex curved shapes or patterns.

What are some common applications of circular interpolation in CNC?

Circular interpolation is used in a wide range of applications in CNC machining. It is commonly used for creating curved surfaces or patterns in materials, such as in the production of automotive parts, aerospace components, and medical devices. It is also used for drilling holes in circular patterns, such as in printed circuit boards or gears. Additionally, circular interpolation can be used to create decorative patterns or designs on materials, such as in the production of jewelry or artwork.

Overall, circular interpolation is a versatile and essential technique in CNC machining, offering precise control over circular paths and enabling the production of complex curved shapes and patterns.

What are some potential challenges with circular interpolation in CNC?

While circular interpolation in CNC machining offers many benefits, there are potential challenges to consider. One challenge is the need for precise programming and calibration, as even small errors in the programming or machine calibration can result in inaccuracies or defects in the finished product. Additionally, circular interpolation can be time-consuming and may require multiple passes to achieve the desired result, which can increase production times and costs. Finally, circular interpolation may not be suitable for all materials or applications, as it can result in excess material removal or other issues in certain circumstances.

Despite these challenges, circular interpolation remains a valuable and widely used technique in CNC machining, offering precise control over circular paths and enabling the creation of complex curved shapes and patterns.

In conclusion, circular interpolation is a critical component of computer numerical control (CNC) machining. It enables the creation of intricate and precise circular paths that are essential for the production of complex parts and components. By programming the CNC machine to execute circular interpolation, manufacturers can achieve greater accuracy and efficiency in their operations.

Moreover, circular interpolation has numerous applications in various industries such as aerospace, automotive, and medical devices. CNC machines equipped with circular interpolation capabilities are highly sought after by manufacturers and offer a competitive edge in the market. The ability to produce parts with smooth curves and contours translates to better aesthetics and functionality of the final product.

In summary, circular interpolation is a powerful tool that has revolutionized the manufacturing industry. Its ability to execute complex circular paths with precision and accuracy has made it an essential component of CNC machining. As technology continues to advance, we can expect circular interpolation to be further refined, enabling manufacturers to produce even more complex and intricate parts.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com