Table of Contents

- How to Set Up a CNC Milling Machine: A Step-by-Step Guide

- Step 1: Install the Software and Drivers

- Step 2: Connect the Machine to Your Computer

- Step 3: Load the Material and Tools

- Step 4: Set the Work Origin

- Step 5: Set the Cutting Parameters

- Step 6: Test the Machine

- Step 7: Start Milling

- Step 8: Clean Up

- Step 9: Maintenance

- Step 10: Benefits of CNC Milling Machines

- Freequently Asked Questions

- What are the steps to set up a CNC Milling Machine?

- What kind of software is needed to operate a CNC Milling Machine?

- What are some common problems that can occur when setting up a CNC Milling Machine?

- What are some tips for optimizing the performance of a CNC Milling Machine?

- What are some safety considerations when setting up and using a CNC Milling Machine?

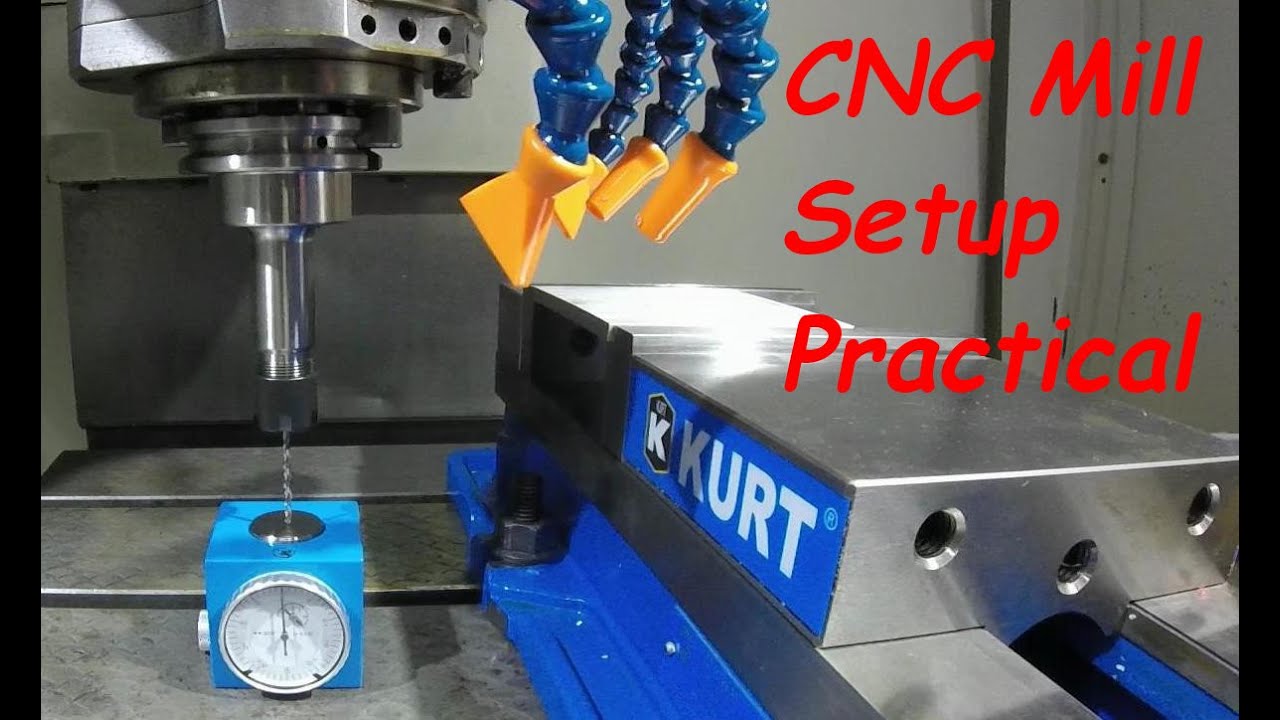

CNC milling is a popular manufacturing process that involves the use of computer-controlled machines to shape and cut materials. One of the most important steps in this process is the setup of the CNC milling machine. Proper setup ensures that the machine operates smoothly and produces high-quality finished products. In this article, we’ll provide a step-by-step guide on how to set up a CNC milling machine, covering everything from safety precautions to tool selection and machine calibration. Whether you’re a seasoned machinist or a beginner, this guide will help you get started with CNC milling and achieve precise, consistent results.

How to Set Up a CNC Milling Machine?

- Prepare the machine and workspace by cleaning and securing all necessary components.

- Install the cutting tools in the machine’s spindle and load the program into the computer.

- Set the workpiece in the machine’s vise or clamps and adjust the tool’s position using the computer’s controls.

- Run a test program to ensure proper tool paths and make any necessary adjustments.

- Begin milling the workpiece and monitor the process for any issues or errors.

- Once the milling is complete, remove the workpiece and clean the machine and workspace.

How to Set Up a CNC Milling Machine: A Step-by-Step Guide

If you’re new to milling, setting up a CNC milling machine can be a daunting task. However, with the right tools and guidance, you can easily get your milling machine up and running in no time. In this article, we’ll provide a step-by-step guide on how to set up your CNC milling machine and ensure it’s ready for action.

Step 1: Install the Software and Drivers

Before you can start using your CNC milling machine, you need to install the necessary software and drivers. This includes the software that controls the machine and the drivers that allow your computer to communicate with it. Most CNC milling machines come with installation CDs or downloadable software from the manufacturer’s website. Once you have the software and drivers, follow the instructions to install them on your computer.

After installation, you’ll need to configure the software to communicate with your milling machine. This typically involves setting up the serial port, baud rate, and other communication settings. Refer to your machine’s user manual for specific instructions on how to configure the software.

Step 2: Connect the Machine to Your Computer

Once you have the software and drivers installed, you need to connect your CNC milling machine to your computer. This is typically done using a serial cable or USB cable. Make sure the cable is securely plugged into both the machine and your computer.

After connecting the cable, turn on your CNC milling machine and make sure it’s powered up and ready to go. Some machines require you to manually calibrate the machine before using it, so refer to your user manual for specific calibration instructions.

Step 3: Load the Material and Tools

Now that your machine is connected and calibrated, it’s time to load the material and tools you’ll be using for your milling project. Make sure you have all the necessary materials and tools before you begin. This may include raw materials, cutting tools, and clamping devices.

Once you have everything you need, carefully load the material onto the milling machine’s worktable. Make sure it’s securely clamped down and won’t move during the milling process.

Step 4: Set the Work Origin

The work origin is the point on the material where the milling process will begin. This needs to be set before you can start milling. To set the work origin, you’ll need to use the machine’s software to move the cutting tool to the desired starting point on the material. Once you’ve positioned the tool, set the work origin in the software.

Step 5: Set the Cutting Parameters

Before you start milling, you need to set the cutting parameters in the machine’s software. This includes the speed, feed rate, and depth of cut. Refer to the material you’re milling and the cutting tool you’re using to determine the appropriate cutting parameters. Setting the correct cutting parameters will ensure a clean and accurate cut.

Step 6: Test the Machine

Now that everything is set up, it’s time to test the machine before you start your actual milling project. This involves running a test cut on a small piece of material to make sure everything is working properly. If there are any issues, you can make adjustments before starting your actual project.

Step 7: Start Milling

With everything tested and ready to go, it’s time to start milling. Follow the cutting parameters you set earlier and let the machine do its work. Keep an eye on the milling process to ensure everything is going smoothly.

Step 8: Clean Up

Once you’ve finished milling, it’s important to clean up the work area and the milling machine itself. Remove any leftover material and tools from the worktable, and use a brush or vacuum to remove any debris. Wipe down the machine with a clean cloth to remove any dust or debris.

Step 9: Maintenance

Regular maintenance is important to keep your CNC milling machine in good working condition. This includes cleaning the machine regularly, lubricating moving parts, and checking for any signs of wear or damage. Refer to your machine’s user manual for specific maintenance instructions.

Step 10: Benefits of CNC Milling Machines

CNC milling machines offer a number of benefits over traditional milling machines. They provide greater accuracy, faster milling times, and the ability to create more complex shapes and designs. They’re also more efficient, requiring less manual labor and reducing the risk of errors.

In summary, setting up a CNC milling machine involves installing the necessary software and drivers, connecting the machine to your computer, loading the material and tools, setting the work origin and cutting parameters, testing the machine, starting the milling process, cleaning up, and performing regular maintenance. With these steps in mind, you can easily set up and use your CNC milling machine to create precision parts and components.

Freequently Asked Questions

In this section, we have answered some of the most common questions related to setting up a CNC Milling Machine. Read on to find out more.

What are the steps to set up a CNC Milling Machine?

Setting up a CNC Milling Machine involves several steps. Firstly, you need to ensure that the machine is properly grounded and that all the components are securely in place. Next, you need to install and calibrate the cutting tools, and make sure that the workpiece is secured in the correct position. Then, you need to input the code for the program to be run, and verify that the machine is operating correctly. Finally, you need to monitor the machine during operation to ensure that everything is running smoothly, and make adjustments as necessary.

It’s important to follow the manufacturer’s instructions carefully when setting up a CNC Milling Machine, and to take the time to ensure that everything is done correctly. This will help to ensure that the machine operates safely and efficiently, and that you achieve the best possible results from your work.

What kind of software is needed to operate a CNC Milling Machine?

To operate a CNC Milling Machine, you will need specialized software that is designed to work with the machine. This software is typically provided by the manufacturer of the machine, and is customized to work with the specific machine that you are using. The software is used to create and edit the program that controls the machine, and to manage the various settings and parameters that are used during operation.

There are many different types of CNC software available, ranging from basic programs for simple machines to more advanced software for complex machines. When choosing software for your CNC Milling Machine, it’s important to consider your specific needs and requirements, as well as the capabilities of the machine itself.

What are some common problems that can occur when setting up a CNC Milling Machine?

Setting up a CNC Milling Machine can be a complex process, and there are several common problems that can occur. One of the most common problems is misalignment of the workpiece, which can cause the machine to cut incorrectly or even damage the workpiece. Another common problem is incorrect tool selection, which can result in poor-quality cuts or even damage to the cutting tools.

Other common problems that can occur when setting up a CNC Milling Machine include incorrect machine calibration, programming errors, and issues with the machine’s electrical or mechanical components. To avoid these problems, it’s important to carefully follow the manufacturer’s instructions and to take the time to properly calibrate and test the machine before use.

What are some tips for optimizing the performance of a CNC Milling Machine?

Optimizing the performance of a CNC Milling Machine involves several factors. Firstly, it’s important to ensure that the machine is properly calibrated and that all the components are working correctly. This will help to ensure that the machine operates efficiently and produces high-quality cuts. Additionally, it’s important to use the correct cutting tools and to keep them properly maintained.

Another key factor in optimizing the performance of a CNC Milling Machine is to use the correct feed and speed rates for the material being cut. This will help to ensure that the machine operates at the optimal speed and produces the best possible results. Finally, it’s important to monitor the machine during operation and to make adjustments as necessary to optimize performance and prevent problems from occurring.

What are some safety considerations when setting up and using a CNC Milling Machine?

When setting up and using a CNC Milling Machine, there are several important safety considerations to keep in mind. Firstly, it’s important to ensure that the machine is properly grounded and that all the components are securely in place. Additionally, it’s important to wear appropriate personal protective equipment, such as safety glasses and gloves, to protect against flying debris and other hazards.

Other important safety considerations when using a CNC Milling Machine include ensuring that the machine is properly ventilated to prevent the buildup of hazardous fumes or dust, and ensuring that the workpiece is properly secured to prevent it from moving during operation. It’s also important to follow all manufacturer’s instructions carefully, and to never operate the machine unless you have been properly trained and certified to do so.

In conclusion, setting up a CNC milling machine requires a combination of technical skills and attention to detail. By following the steps outlined in this guide and ensuring that all necessary precautions are taken, you can successfully set up your machine and begin producing high-quality parts with ease.

Remember to always consult the manufacturer’s instructions and seek professional assistance if needed. With proper maintenance and care, your CNC milling machine will continue to serve you well for years to come.

So, whether you are a seasoned professional or a beginner, take the time to learn the basics of setting up a CNC milling machine. With a little bit of practice and patience, you’ll soon be able to create complex parts and designs with precision and accuracy.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com