Table of Contents

CNC (Computer Numerical Control) milling and turning are two of the most important techniques in the manufacturing industry. They are used to create precise and accurate parts and components that are used in a wide range of applications. CNC machines are becoming increasingly popular due to their ability to produce high-quality parts at a rapid pace.

CNC milling and turning are both subtractive manufacturing processes that involve removing material from a workpiece to create a finished part. CNC machines use computer-controlled movements to precisely remove material from a block of raw material, such as metal or plastic, to create the desired shape and size. These machines are used in a variety of industries, including automotive, aerospace, and medical device manufacturing.

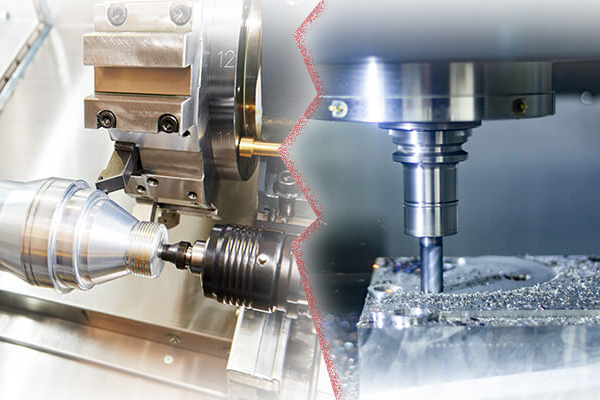

CNC milling and turning are two manufacturing processes that involve the use of computer numerical control (CNC) machines. CNC milling involves the use of a rotating cutting tool to remove material from a workpiece, while CNC turning involves the use of a stationary cutting tool to create a cylindrical shape. Both processes are widely used in the manufacturing industry to produce high-precision parts and components.

Understanding CNC Milling and Turning

CNC milling and turning are two of the most commonly used machining techniques in modern manufacturing. These processes are used to create complex parts and components, often with high precision and accuracy. In this article, we will explore the basics of CNC milling and turning, how they work, and their applications in various industries.

What is CNC Milling?

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece. The process involves a cutting tool that rotates at high speeds and removes material from the workpiece to create the desired shape. The machine is controlled by a computer program that specifies the tool path and the depth of the cut.

CNC milling machines can produce a wide range of shapes and sizes, from simple flat surfaces to complex three-dimensional shapes. The machines can also work with a variety of materials, including metals, plastics, and composites. CNC milling is used in a variety of industries, including aerospace, automotive, and medical.

The Benefits of CNC Milling

– Precision and accuracy: CNC milling machines can produce highly precise and accurate parts, with tolerances as small as a few microns.

– Versatility: CNC milling machines can work with a variety of materials and produce a wide range of shapes and sizes.

– Efficiency: CNC milling machines can produce parts quickly and efficiently, reducing production time and costs.

CNC Milling Vs. Traditional Milling

Traditional milling is a manual process that involves a cutting tool and a workpiece. The operator controls the movement of the tool and removes material from the workpiece. CNC milling, on the other hand, is a computer-controlled process that uses automated machines to produce parts. CNC milling is faster, more accurate, and more efficient than traditional milling.

What is CNC Turning?

CNC turning is a subtractive manufacturing process that uses computer-controlled machines to remove material from a cylindrical workpiece. The process involves a cutting tool that moves along the length of the workpiece and removes material to create the desired shape. The machine is controlled by a computer program that specifies the tool path and the depth of the cut.

CNC turning machines can produce a variety of shapes and sizes, including simple cylindrical shapes, threaded parts, and complex three-dimensional shapes. The machines can work with a variety of materials, including metals, plastics, and composites. CNC turning is used in a variety of industries, including aerospace, automotive, and medical.

The Benefits of CNC Turning

– Precision and accuracy: CNC turning machines can produce highly precise and accurate parts, with tolerances as small as a few microns.

– Versatility: CNC turning machines can work with a variety of materials and produce a wide range of shapes and sizes.

– Efficiency: CNC turning machines can produce parts quickly and efficiently, reducing production time and costs.

CNC Turning Vs. Traditional Turning

Traditional turning is a manual process that involves a cutting tool and a cylindrical workpiece. The operator controls the movement of the tool and removes material from the workpiece. CNC turning, on the other hand, is a computer-controlled process that uses automated machines to produce parts. CNC turning is faster, more accurate, and more efficient than traditional turning.

Conclusion

CNC milling and turning are two essential processes in modern manufacturing. These processes have revolutionized the way we produce parts and components, allowing us to create complex shapes with high precision and accuracy. CNC milling and turning offer a range of benefits, including precision, versatility, and efficiency, making them ideal for a wide range of applications in various industries.

Frequently Asked Questions

Here are some frequently asked questions about CNC Milling and Turning:

What is CNC Milling?

CNC milling is a manufacturing process that involves using computer software to control the movement of a cutting tool. The tool is used to remove material from a workpiece, which is typically made of metal or plastic. CNC milling is often used to create complex shapes and parts that would be difficult or impossible to make with traditional machining methods.

The CNC milling process involves programming the cutting tool’s movements using computer-aided design (CAD) software. The software generates instructions that tell the machine how to move the cutting tool to create the desired shape. The machine then uses these instructions to move the cutting tool along the workpiece, removing material as it goes.

What is CNC Turning?

CNC turning is a manufacturing process that involves using computer software to control the movement of a cutting tool. The tool is used to remove material from a workpiece, which is typically made of metal or plastic. CNC turning is often used to create cylindrical parts, such as shafts, bolts, and nuts.

The CNC turning process involves programming the cutting tool’s movements using computer-aided design (CAD) software. The software generates instructions that tell the machine how to move the cutting tool to create the desired shape. The machine then uses these instructions to rotate the workpiece while the cutting tool removes material, creating a cylindrical shape.

What are the advantages of CNC Milling and Turning?

CNC milling and turning offer several advantages over traditional machining methods. One of the main advantages is precision. Because the cutting tool is controlled by a computer program, it can move with a high degree of accuracy, allowing for very precise cuts and shapes. CNC milling and turning also offer increased efficiency and productivity, as the machines can work continuously without the need for manual intervention.

Another advantage of CNC milling and turning is flexibility. The machines can be easily reprogrammed to create different parts and shapes, making them ideal for small-scale production runs and prototyping. CNC milling and turning also offer improved safety, as the machines can be operated without putting workers at risk of injury.

What materials can be used for CNC Milling and Turning?

CNC milling and turning can be used to work with a wide range of materials, including metals, plastics, and composites. Some common metals used in CNC milling and turning include aluminum, steel, and titanium. Plastics such as ABS, polycarbonate, and nylon are also commonly used. Composites, such as carbon fiber and fiberglass, can also be machined using CNC milling and turning.

The specific material used will depend on the requirements of the part being produced. Factors such as strength, durability, and weight will all need to be taken into account when selecting the material for a particular part.

What industries use CNC Milling and Turning?

CNC milling and turning are used in a wide range of industries, including aerospace, automotive, medical, and electronics. In the aerospace industry, CNC milling and turning are used to create complex parts for aircraft engines and other components. In the automotive industry, CNC milling and turning are used to create parts for engines, transmissions, and suspension systems.

In the medical industry, CNC milling and turning are used to create surgical tools, implants, and prosthetics. In the electronics industry, CNC milling and turning are used to create parts for computers, smartphones, and other electronic devices. CNC milling and turning are also used in the prototyping and manufacturing of consumer goods, such as toys and household appliances.

In conclusion, CNC milling and turning are two of the most important processes in modern manufacturing. These processes have revolutionized the way that products are made, allowing for greater precision, efficiency, and customization. With CNC technology, manufacturers can produce complex parts and components with ease, while maintaining high levels of quality and consistency.

Whether you are looking to create a prototype, a small batch of parts, or a large production run, CNC milling and turning offer a range of benefits that make them a popular choice for manufacturers around the world. From aerospace and automotive to medical and consumer goods, CNC technology is used in a wide range of industries and applications.

So, whether you are a seasoned professional or just starting out in the world of manufacturing, it’s clear that CNC milling and turning are here to stay. With their ability to deliver high-quality, precision parts in a wide range of materials, these processes are sure to continue shaping the future of manufacturing for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com