Table of Contents

If you’re looking to improve the accuracy of your CNC router, you may have heard of T-slots. These specialized tracks allow for the easy and secure attachment of workpiece clamps, and can make a big difference in the precision of your cuts. But are T-slots really a good idea for your CNC router?

In this article, we’ll take a closer look at T-slots and their benefits and drawbacks. We’ll explore the different types of T-slots available, and weigh the pros and cons of incorporating them into your CNC router setup. By the end of this article, you’ll have a better understanding of whether T-slots are a smart investment for your specific needs.

Are T Slots a Good Idea for CNC Router?

When it comes to CNC routers, the right accessories can make all the difference in the world. One accessory that has been gaining popularity over the years is the T slot. But, are T slots a good idea for CNC router? Let’s find out.

What are T Slots?

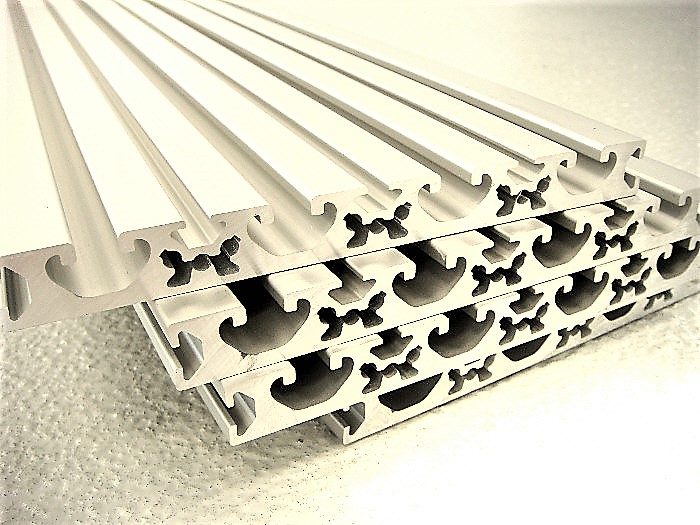

T slots are a type of slot that is used to hold workpieces in place during machining. They are typically found on milling machines and are cut into the table or bed of the machine. T slots are named after the T-shaped groove that is cut into the table. This groove is designed to hold a T-nut, which can then be used to hold a workpiece securely in place.

T slots are now being incorporated into CNC routers as well. This allows for greater flexibility when it comes to holding workpieces in place during machining.

Benefits of T Slots for CNC Routers

There are several benefits to using T slots on a CNC router.

Firstly, T slots provide a more flexible and customizable way to hold workpieces in place. The T-nuts can be moved along the slot to accommodate different sized workpieces. This means that you can hold a wider variety of workpieces securely in place, without having to worry about them moving during machining.

Secondly, T slots provide a more secure hold for the workpiece. Unlike traditional clamps, T slots allow for a more even distribution of force across the workpiece. This means that there is less chance of the workpiece moving or shifting during machining, resulting in a more accurate and precise finished product.

Finally, T slots can save time and increase efficiency. Once the T-nuts are in place, you can quickly and easily change out workpieces without having to spend time readjusting clamps or fixtures.

T Slots vs Traditional Clamps

While T slots offer many benefits, they are not always the best option for every situation. Traditional clamps can still be a viable option for holding workpieces in place, depending on the size and shape of the workpiece.

One advantage of traditional clamps is that they can be used to hold irregularly shaped workpieces. In contrast, T slots are best suited for holding workpieces with flat surfaces.

Traditional clamps can also be more cost-effective than T slots, depending on the number of workpieces that need to be held in place. T slots require an initial investment in the T-nuts and other accessories, which may not be practical for smaller-scale operations.

Conclusion

In conclusion, T slots can be a great addition to a CNC router. They offer a flexible and secure way to hold workpieces in place, while also saving time and increasing efficiency. However, it’s important to remember that T slots are not the best option for every situation. Traditional clamps may still be a viable option, depending on the size and shape of the workpiece. Ultimately, the decision to use T slots or traditional clamps will depend on the specific needs of your operation.

Frequently Asked Questions

Are you considering T-slots for your CNC router? Here are some common questions and answers to help you make an informed decision.

What are T-slots, and how do they work?

T-slots are a type of groove or channel that runs along the surface of a material. They are used to hold other components or parts in place. T-slots are common in CNC routers because they allow for easy and quick clamping of workpieces. The T-slot design allows for a variety of clamping options, including bolts, clamps, and specialized fixtures.

T-slots are typically made of aluminum or steel and come in a variety of sizes and configurations. They are a popular choice for CNC router beds because they allow for maximum flexibility when it comes to holding workpieces in place.

What are the benefits of using T-slots on a CNC router bed?

One of the primary benefits of using T-slots on a CNC router bed is that they provide a flexible and versatile clamping system. This allows for quick and easy set-up and changeover times, as well as the ability to hold a wide range of workpiece sizes and shapes. T-slots also provide a strong and secure hold, which is essential for precision cutting and milling operations.

T-slots are also easy to modify, allowing you to add or remove clamping options as needed. This makes them a cost-effective solution that can be customized to fit your specific needs.

What are the drawbacks of using T-slots on a CNC router bed?

One potential drawback of using T-slots on a CNC router bed is that they can be more difficult to clean and maintain compared to a smooth surface. The grooves can collect debris and dust, which can affect the accuracy of your cuts and require more frequent cleaning.

Another consideration is that T-slots may not be necessary for all applications. If you primarily work with smaller workpieces or have a dedicated holding system in place, T-slots may not provide any additional benefits.

Can T-slots be added to an existing CNC router bed?

Yes, T-slots can be added to an existing CNC router bed. However, this may require modifications to the current bed design and may not be possible on all machines. It’s important to consult with a professional or the manufacturer before making any modifications to your CNC router.

Additionally, adding T-slots may add weight or reduce the rigidity of your machine, which can affect its overall performance. It’s important to carefully consider the pros and cons before making any modifications to your CNC router bed.

Are there alternatives to T-slots for holding workpieces on a CNC router bed?

Yes, there are several alternatives to T-slots for holding workpieces on a CNC router bed. These include vacuum hold-down systems, clamps, and specialized fixtures. The choice of holding system will depend on factors such as the size and shape of your workpieces, the material you are working with, and the precision required for your operations.

It’s important to evaluate your specific needs and requirements before choosing a holding system for your CNC router bed.

In conclusion, T slots are a great addition to any CNC router. They provide versatility and flexibility in holding down materials and fixturing. This feature allows the operator to securely hold down materials and prevents movement during the cutting process, resulting in more accurate cuts and increased productivity.

T slots also provide the ability to easily change out fixtures and accessories, making it easier to adapt to different jobs and projects. This feature saves time and money by reducing the need for custom fixtures and tooling, which can be expensive and time-consuming to create.

Overall, T slots are a valuable feature to have on a CNC router. They enhance the capabilities of the machine and improve the quality and efficiency of the cutting process. If you are looking to upgrade your CNC router or invest in a new one, be sure to consider the benefits of T slots.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com