Table of Contents

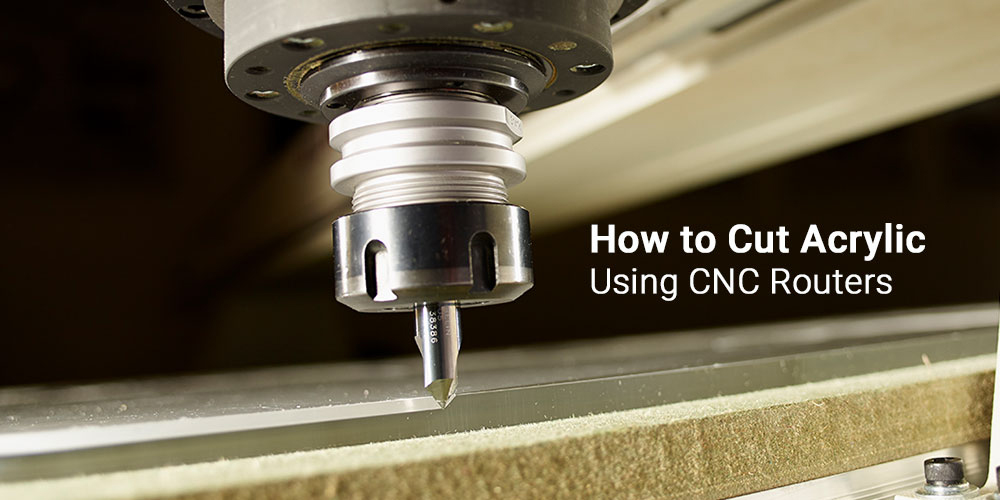

CNC machines are widely used in the manufacturing industry to cut, carve, and shape different materials with precision and accuracy. One question that often arises is whether these machines can cut acrylic, a popular material used in various applications.

The short answer is yes, CNC machines can cut acrylic. However, there are certain factors that need to be considered, such as the type of acrylic, the thickness of the material, and the cutting speed and depth. In this article, we will explore these factors in detail to help you understand how CNC machines can effectively cut acrylic.

Can a CNC Machine Cut Acrylic?

Acrylic, also known as plexiglass or PMMA, is a popular material in the manufacturing industry due to its durability, transparency, and versatility. However, cutting acrylic can be a challenging task. Many types of equipment are available for cutting acrylic, but can a CNC machine cut acrylic? In this article, we will explore the capabilities of CNC machines in cutting acrylic.

Understanding CNC Machines

CNC machines are computer-controlled machines that can perform various tasks, including cutting, drilling, milling, and shaping materials. These machines use computer-aided design (CAD) software to create a design, which is then translated into a set of instructions that the CNC machine follows to perform the desired task.

The Benefits of CNC Machines

One of the main advantages of using a CNC machine is its accuracy and precision. These machines can produce highly complex designs with consistent results. CNC machines are also efficient and can complete tasks quickly, reducing labor costs and increasing productivity.

CNC Machine Vs Traditional Methods

Compared to traditional methods of cutting acrylic, such as using a saw or laser cutting, CNC machines offer several advantages. CNC machines can cut acrylic with greater precision, resulting in a cleaner and more polished finish. They can also cut thicker sheets of acrylic, up to several inches thick, unlike laser cutting, which has a limited thickness capacity.

The Capabilities of CNC Machines in Cutting Acrylic

CNC machines are capable of cutting acrylic sheets into various shapes and sizes with precision and accuracy. They can also create intricate designs, patterns, and even 3D shapes. CNC machines can cut acrylic into various forms, including:

- Straight cuts

- Curved cuts

- Bevel cuts

- Chamfer cuts

- Engraving and etching

Benefits of CNC Machines for Acrylic Cutting

CNC machines offer several benefits when cutting acrylic. They can produce consistent results, regardless of the complexity of the design. CNC machines can also reduce waste by optimizing the cutting process, minimizing scrap material. Additionally, CNC machines can cut acrylic sheets with a smooth and polished finish, reducing the need for additional finishing processes.

Precautions When Cutting Acrylic with a CNC Machine

Although CNC machines are highly efficient and accurate, precautions must be taken when cutting acrylic. First, it is essential to select the appropriate cutting tool, such as a carbide or diamond-tipped router bit. Second, the cutting speed and feed rate must be optimized to prevent overheating and melting of the acrylic material. Finally, proper ventilation and eye protection must be used to prevent inhalation of acrylic dust and eye damage.

Conclusion

In conclusion, CNC machines are highly capable of cutting acrylic sheets into various shapes and sizes with precision and accuracy. Compared to traditional cutting methods, CNC machines offer several advantages, including greater precision, efficiency, and the ability to cut thicker sheets of acrylic. However, precautions must be taken when cutting acrylic with a CNC machine to optimize results and ensure safety.

Frequently Asked Questions

Acrylic is a popular material used in various industries due to its durability and transparency. With the advancement in technology, CNC machines have become more accessible to businesses and individuals. If you are interested in cutting acrylic using a CNC machine, here are answers to some frequently asked questions.

Can a CNC Machine Cut Acrylic?

Yes, a CNC machine can cut acrylic. In fact, acrylic is one of the most commonly cut materials using a CNC machine. CNC machines are capable of cutting acrylic with precision and accuracy, making them an ideal choice for various applications.

However, it is important to note that not all CNC machines are created equal. Some machines may not be suitable for cutting acrylic, while others may require specific settings or tools to achieve the desired results. It is best to consult with the manufacturer or a CNC expert before attempting to cut acrylic with a CNC machine.

What Type of CNC Machine is Best for Cutting Acrylic?

There are various types of CNC machines available in the market, each with its own strengths and weaknesses. When it comes to cutting acrylic, a CNC router is the most suitable option. CNC routers are designed to cut materials with precision and speed, making them ideal for cutting acrylic sheets of different sizes and thicknesses.

It is important to choose a CNC router with a high-quality spindle and cutting bits specifically designed for cutting acrylic. Additionally, the machine should have a strong and rigid frame to ensure stability during the cutting process.

What Factors Affect the CNC Cutting of Acrylic?

Several factors can affect the CNC cutting of acrylic, including the speed, feed rate, cutting bit, and spindle. The speed and feed rate determine how fast the cutting bit moves through the acrylic, while the cutting bit and spindle affect the quality of the cut.

In addition, the thickness and size of the acrylic sheet can also affect the cutting process. Thicker sheets may require slower speeds and different cutting bits to ensure a clean and accurate cut. It is important to experiment with different settings and tools to achieve the best results.

What Precautions Should I Take When Cutting Acrylic with a CNC Machine?

Working with a CNC machine can be dangerous, and cutting acrylic can create sharp edges and debris. It is important to wear personal protective equipment, such as gloves and safety glasses, to prevent injury.

Additionally, the cutting area should be well-ventilated to prevent the buildup of acrylic dust and fumes. It is also important to secure the acrylic sheet properly to prevent it from moving or vibrating during the cutting process.

What Applications Can CNC-Cut Acrylic be Used For?

CNC-cut acrylic sheets are versatile and can be used for various applications, including signage, displays, lighting fixtures, and furniture. Acrylic is also commonly used in the automotive and aerospace industries due to its durability and transparency.

CNC machines can create intricate designs and shapes with ease, making acrylic an ideal material for custom projects and prototypes. With the right tools and settings, CNC-cut acrylic can achieve a professional and polished look that is sure to impress.

In conclusion, a CNC machine can definitely cut acrylic. With its precision and accuracy, CNC machines can easily cut through acrylic sheeting without causing any cracks or damages. It is the perfect tool for creating intricate designs and shapes with high-quality finishes.

Moreover, CNC machines offer a faster and more efficient way of cutting acrylic compared to traditional methods. With its computerized programming, CNC machines can produce multiple pieces with consistent quality, which saves time and reduces waste.

Finally, CNC machines can also cut acrylic with various thicknesses and sizes, making it ideal for different projects and applications. Whether it’s for signage, jewelry, or home decor, a CNC machine can cut acrylic with ease and excellence, providing endless possibilities for creativity and innovation.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com