Table of Contents

- Can Extruded Aluminum Be a Heatsink?

- Frequently Asked Questions

- 1. Can extruded aluminum be an effective heatsink material?

- 2. What are the advantages of using extruded aluminum as a heatsink material?

- 3. What are the limitations of using extruded aluminum as a heatsink material?

- 4. How can the cooling performance of extruded aluminum heatsinks be improved?

- 5. What are some factors to consider when designing an extruded aluminum heatsink?

Extruded aluminum is a popular material for heatsinks due to its excellent thermal conductivity and cost-effectiveness. However, many people still wonder if it is a viable option for their specific application. In this article, we will explore the benefits and limitations of using extruded aluminum as a heatsink and provide some insights on how to make the most of this material.

Heat dissipation is crucial in many industries, from electronics to automotive, and extruded aluminum has become a go-to choice for many engineers and designers. But what makes it so special? And is it suitable for all types of heatsinks? Let’s dive into the world of extruded aluminum and find out if it can be the right choice for your thermal management needs.

Can Extruded Aluminum Be a Heatsink?

When it comes to thermal management, heatsinks are an essential component of many electronic devices. They help to dissipate heat generated by electronic components, preventing overheating and potentially damaging the device. One type of heatsink that has gained popularity in recent years is extruded aluminum heatsinks. But can extruded aluminum be a heatsink? In this article, we will delve into the details and explore the benefits and drawbacks of using extruded aluminum as a heatsink material.

What is Extruded Aluminum?

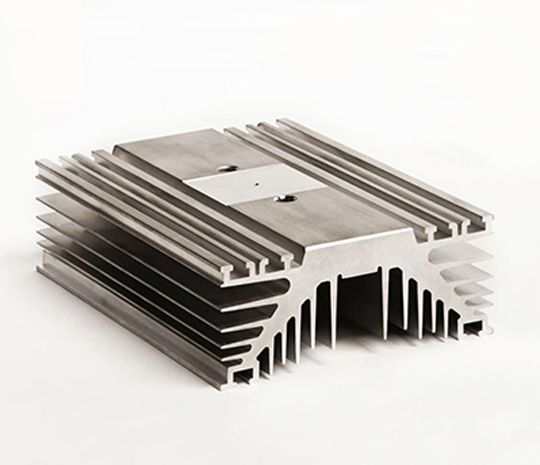

Extruded aluminum is a type of aluminum that has been transformed into a specific shape or profile through a process called extrusion. This process involves heating a cylindrical billet of aluminum to a temperature where it becomes malleable and can be pushed through a die to create a specific shape. The resulting extruded aluminum profile can be used in a variety of applications, including heatsinks.

Benefits of Using Extruded Aluminum as a Heatsink

There are several benefits of using extruded aluminum as a heatsink material. One of the most significant advantages is its excellent thermal conductivity. Aluminum is a good conductor of heat, and extruded aluminum heatsinks can efficiently dissipate heat generated by electronic components. Additionally, extruded aluminum heatsinks are lightweight and can be easily machined into complex shapes, making them ideal for a wide range of applications.

Another benefit of using extruded aluminum as a heatsink material is its corrosion resistance. Aluminum naturally forms a thin layer of oxide on its surface, which protects it from corrosion. This means that extruded aluminum heatsinks can be used in harsh environments without the risk of rust or other forms of corrosion.

Drawbacks of Using Extruded Aluminum as a Heatsink

While there are many benefits to using extruded aluminum as a heatsink material, there are also some drawbacks to consider. One of the most significant drawbacks is its low thermal capacity. Aluminum has a lower thermal capacity than other metals such as copper, which means that it can’t absorb and hold as much heat. This can limit the effectiveness of extruded aluminum heatsinks in applications where a high rate of heat dissipation is required.

Another potential drawback of using extruded aluminum as a heatsink material is its lower strength compared to other metals. While aluminum is a relatively strong metal, it may not be suitable for applications where high stress or impact loads are expected. In such cases, it may be necessary to use a different material for the heatsink.

Extruded Aluminum vs. Other Heatsink Materials

When it comes to heatsink materials, there are several options available, each with its own set of benefits and drawbacks. Here is a comparison of extruded aluminum heatsinks against some other commonly used heatsink materials.

Extruded Aluminum vs. Copper Heatsinks

Copper is a popular choice for heatsinks due to its excellent thermal conductivity. Copper heatsinks can efficiently dissipate heat generated by electronic components, making them ideal for high-performance applications. However, copper is also a heavy metal and can be expensive compared to aluminum. Additionally, copper heatsinks may not be suitable for applications where weight is a concern.

Extruded Aluminum vs. Steel Heatsinks

Steel is another commonly used material for heatsinks, particularly in industrial applications. Steel heatsinks are strong and durable, making them suitable for high-stress applications. However, steel has a lower thermal conductivity than aluminum, which means that it may not be as effective at dissipating heat.

Extruded Aluminum vs. Heat Pipe Heatsinks

Heat pipe heatsinks are a type of heatsink that uses a hollow tube filled with a coolant to transfer heat away from electronic components. Heat pipe heatsinks can be very effective at dissipating heat and are often used in high-performance applications. However, they can be expensive and may not be suitable for applications where weight is a concern.

Conclusion

In conclusion, extruded aluminum can be an effective material for heatsinks, particularly in applications where weight and cost are a concern. While it may not have the same thermal conductivity or capacity as other metals such as copper, it can still efficiently dissipate heat generated by electronic components. When choosing a heatsink material, it’s essential to consider the specific requirements of the application to determine which material will be the most effective.

Frequently Asked Questions

Extruded aluminum is commonly used in the manufacturing of heatsinks because of its excellent heat dissipation properties. Here are five frequently asked questions and answers regarding the use of extruded aluminum as a heatsink.

1. Can extruded aluminum be an effective heatsink material?

Yes, extruded aluminum is an excellent heatsink material because it has a high thermal conductivity, which means it can transfer heat quickly and efficiently away from the heat source. It is also lightweight, durable, and cost-effective compared to other materials like copper.

The extrusion process also allows for the creation of a wide range of shapes and sizes, making it a versatile option for different heatsink designs. The surface area of the heatsink can also be increased by adding fins, which further enhances its cooling performance.

2. What are the advantages of using extruded aluminum as a heatsink material?

The main advantage of using extruded aluminum as a heatsink material is its excellent heat dissipation properties. It has a high thermal conductivity, which means it can transfer heat quickly and efficiently away from the heat source.

Extruded aluminum is also lightweight, durable, and cost-effective compared to other materials like copper. It is also easy to work with, allowing for the creation of different heatsink shapes and sizes. Additionally, the surface area of the heatsink can be increased by adding fins, which further enhances its cooling performance.

3. What are the limitations of using extruded aluminum as a heatsink material?

While extruded aluminum is an excellent heatsink material, it does have some limitations. One limitation is its thermal conductivity, which is lower than other materials like copper. This means that it may not be as effective in dissipating heat in high-power applications.

Another limitation is its mechanical strength, which may not be suitable for some applications that require high-stress resistance. The surface of the heatsink may also be prone to oxidation and corrosion, which can affect its cooling performance over time.

4. How can the cooling performance of extruded aluminum heatsinks be improved?

The cooling performance of extruded aluminum heatsinks can be improved by increasing the surface area of the heatsink. This can be done by adding fins or other features that increase the surface area exposed to the air.

Another way to improve cooling performance is by using thermal interface materials like thermal paste or pads. These materials help to improve the thermal contact between the heat source and the heatsink, which can improve heat transfer.

5. What are some factors to consider when designing an extruded aluminum heatsink?

When designing an extruded aluminum heatsink, there are several factors to consider. These include the thermal requirements of the application, the size and shape of the heatsink, the airflow and cooling requirements, and the mechanical strength needed for the application.

Other factors to consider include the materials used, the manufacturing process, and the cost of production. Designers should also consider the aesthetics and overall design of the heatsink, as it can affect the performance and functionality of the final product.

In conclusion, extruded aluminum can be an excellent heatsink material. Its high thermal conductivity and ability to dissipate heat make it a popular choice in various industries, including electronics and automotive. However, the design and manufacturing process of the aluminum heatsink must be carefully considered to ensure optimal performance.

When designing an extruded aluminum heatsink, it’s crucial to take into account its size, shape, and surface area. A larger surface area will increase the heatsink’s ability to dissipate heat, while a well-designed shape can enhance its thermal performance. Additionally, the surface finish of the heatsink can affect its ability to transfer heat efficiently.

Overall, extruded aluminum has proven to be a reliable and efficient heatsink material. Its versatility and cost-effectiveness make it a popular choice for many applications. However, it’s essential to work with experienced manufacturers and designers to ensure that the heatsink is appropriately designed and manufactured for optimal performance.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com