Table of Contents

- Can I Use a CNC Bit in a Standard Router?

- Frequently Asked Questions

- Can I use a CNC bit in a standard router?

- What is the difference between a CNC bit and a standard router bit?

- Can I modify a standard router bit to work with a CNC machine?

- What are the advantages of using a CNC machine over a standard router?

- What should I consider when choosing between a CNC machine and a standard router?

If you’re a woodworking enthusiast, you’ve likely heard of Computer Numerical Control (CNC) machines. These powerful tools can create intricate designs with precision and speed. But what if you don’t have a CNC machine and want to achieve similar results? Can you use a CNC bit in a standard router?

The short answer is yes, you can use a CNC bit in a standard router. However, there are some important factors to consider before doing so. In this article, we’ll explore the differences between CNC bits and standard router bits, the compatibility of CNC bits with standard routers, and some tips for getting the best results.

It is not recommended to use a CNC bit in a standard router because they are designed for different purposes. A CNC bit is specifically designed for use with a computer numerical control (CNC) machine and has a shank size that may not fit into a standard router’s collet. Additionally, standard routers do not have the necessary speed and power to properly handle CNC bits, which can result in poor performance and potential safety hazards. It is best to use the appropriate tool for the job.

Can I Use a CNC Bit in a Standard Router?

If you are a DIY enthusiast or a professional woodworker, you may have wondered if you could use a CNC bit in a standard router to cut, carve or shape wood. CNC (Computer Numerical Control) bits are designed to work with CNC machines, which are computer-controlled tools that automate the cutting process. In this article, we will explore whether you can use a CNC bit in a standard router and what are the benefits and drawbacks of doing so.

What is a CNC Bit?

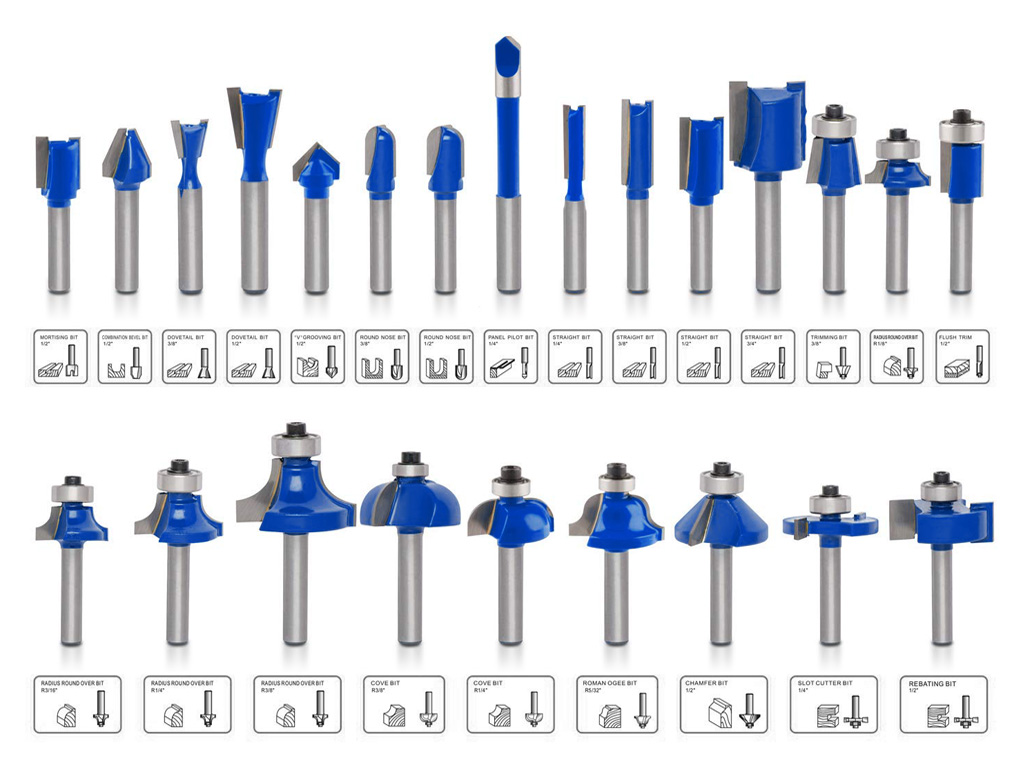

A CNC bit is a specialized cutting tool that is designed to be used with a CNC machine. It is usually made of high-speed steel, carbide or diamond, and comes in different shapes and sizes, depending on the type of cutting operation it is meant for. CNC bits are designed to cut materials with high precision and accuracy, and they are optimized for the high speeds and feeds of CNC machines. They are often used for industrial applications, such as cutting metal, plastic, and wood.

However, it is possible to use a CNC bit in a standard router, although there are some limitations and considerations to keep in mind.

Benefits of Using a CNC Bit in a Standard Router

One of the main benefits of using a CNC bit in a standard router is that it can increase the precision and accuracy of the cutting operation. CNC bits are designed to cut with high precision, which can be useful for intricate or complex cuts, such as carving or engraving. They can also produce smoother cuts and cleaner edges than standard router bits.

Another benefit is that CNC bits are often made of high-quality materials, such as carbide, which can increase their durability and lifespan. This can be especially useful if you plan to use your router frequently or for heavy-duty projects.

Drawbacks of Using a CNC Bit in a Standard Router

One of the main drawbacks of using a CNC bit in a standard router is that it may not be compatible with the router’s collet. CNC bits are often designed to fit into specialized collets that are used with CNC machines, which may not be compatible with standard router collets. This can make it difficult or impossible to use a CNC bit with a standard router, depending on the type and size of the bit.

Another drawback is that CNC bits are often optimized for high-speed cutting operations, which may not be suitable for use with a standard router. Standard routers typically operate at lower speeds than CNC machines, which can cause the bit to overheat or wear out faster than usual.

Can You Use a CNC Bit in a Standard Router?

The answer to this question depends on several factors, such as the type and size of the CNC bit, the type of router you have, and the type of material you are cutting. In general, it is possible to use a CNC bit in a standard router, but it may require some modifications or adjustments.

Modifications You May Need to Make

If you want to use a CNC bit in a standard router, you may need to make some modifications or adjustments to the router or the bit. Here are some things to consider:

- Collet size: Make sure the collet on your router is compatible with the shank size of the CNC bit. If not, you may need to buy a specialized collet or adapter.

- Speed: Make sure you are using the correct speed for the type of material you are cutting and the size of the bit. CNC bits are designed to operate at high speeds, so you may need to adjust the speed settings on your router accordingly.

- Depth of cut: Make sure you are not cutting too deeply with the bit, as this can cause it to overheat or break. Use a depth gauge to measure the depth of the cut, and adjust as necessary.

When to Use a CNC Bit in a Standard Router

Using a CNC bit in a standard router can be useful in certain situations, such as when you need to make precise or intricate cuts, or when you want to achieve a smoother finish than standard router bits can provide. It can also be useful if you already have a CNC bit on hand and don’t want to buy a separate router bit for a specific project.

However, it is important to keep in mind the limitations and drawbacks of using a CNC bit in a standard router, such as the potential compatibility issues with collets and the need to adjust the speed and depth of cut settings.

When Not to Use a CNC Bit in a Standard Router

There are also situations where it may not be advisable to use a CNC bit in a standard router, such as when you are cutting harder or thicker materials that require more power and torque than a standard router can provide. In these cases, it may be better to use a specialized router bit that is designed specifically for the type of material you are cutting.

Conclusion

In conclusion, it is possible to use a CNC bit in a standard router, but it may require some modifications or adjustments. It can be useful in certain situations, such as when you need to make precise or intricate cuts or when you want to achieve a smoother finish. However, it is important to keep in mind the limitations and drawbacks of using a CNC bit in a standard router, and to use it only when it is appropriate and safe to do so.

Frequently Asked Questions

If you’re into woodworking, you might be wondering whether you can use a CNC bit in a standard router. Here are some questions and answers that will help you understand the differences between the two and whether it’s possible to use one in the other.

Can I use a CNC bit in a standard router?

While CNC bits and standard router bits may look similar, they are not interchangeable. CNC bits are specifically designed for use with computer numerical control (CNC) machines, while standard router bits are designed for handheld use in a router. CNC bits have a longer shank and a different type of cutting edge than standard router bits, which allows them to be used in CNC machines.

Trying to use a CNC bit in a standard router could result in damage to both the bit and the router. It’s best to use the appropriate type of bit for your machine to ensure optimal performance and safety.

What is the difference between a CNC bit and a standard router bit?

As mentioned earlier, CNC bits are designed for use with CNC machines, which are computer-controlled and highly precise. CNC bits have a longer shank and a different type of cutting edge than standard router bits, which allows them to be used in CNC machines. Standard router bits, on the other hand, are designed for handheld use in routers and have a shorter shank and a different type of cutting edge that allows for more maneuverability.

Overall, CNC bits are more expensive than standard router bits, but they offer greater precision and efficiency when used with a CNC machine.

Can I modify a standard router bit to work with a CNC machine?

It’s not recommended to modify a standard router bit to work with a CNC machine. CNC bits are specifically designed for use with CNC machines and have a longer shank and a different type of cutting edge than standard router bits. Modifying a standard router bit could result in damage to both the bit and the machine, and it could also compromise the safety of the user.

If you’re looking to use a CNC machine, it’s best to invest in the appropriate type of bit for your machine to ensure optimal performance and safety.

What are the advantages of using a CNC machine over a standard router?

CNC machines offer greater precision and efficiency than standard routers. Because they are computer-controlled, CNC machines can perform highly precise cuts and designs that would be difficult or impossible to achieve with a standard router. CNC machines also allow for greater repeatability and consistency, which can be important for large-scale manufacturing or production.

However, CNC machines are typically more expensive than standard routers and require more specialized knowledge and training to operate. For hobbyists or occasional woodworkers, a standard router may be a more practical and cost-effective option.

What should I consider when choosing between a CNC machine and a standard router?

When choosing between a CNC machine and a standard router, it’s important to consider your budget, the types of projects you’ll be working on, and your level of experience and expertise. CNC machines are typically more expensive than standard routers, but they offer greater precision and efficiency for those who require it. Standard routers are more affordable and user-friendly, making them a good option for hobbyists or those who only work on projects occasionally.

Ultimately, the decision between a CNC machine and a standard router will depend on your individual needs and preferences. It’s important to do your research and choose the option that will best suit your woodworking needs.

In conclusion, it is possible to use a CNC bit in a standard router with some adjustments. However, it is important to note that not all CNC bits are compatible with standard routers, and vice versa.

If you are planning to use a CNC bit in a standard router, make sure to check the specifications of both tools and ensure that they are compatible. Additionally, you may need to make adjustments to the router’s speed settings and depth of cut to ensure a smooth and accurate cut.

Overall, using a CNC bit in a standard router can expand your capabilities and provide more versatility in your woodworking projects. Just remember to take the necessary precautions and make the proper adjustments to ensure a successful outcome.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com