Table of Contents

EPDM, which stands for ethylene propylene diene monomer, is a highly durable rubber material that is often used in various industrial applications due to its excellent weather resistance and chemical stability. However, when it comes to manufacturing EPDM parts, many people wonder if injection molding is a viable option. In this article, we will explore the question of whether or not EPDM can be injection molded, and what factors may affect the process.

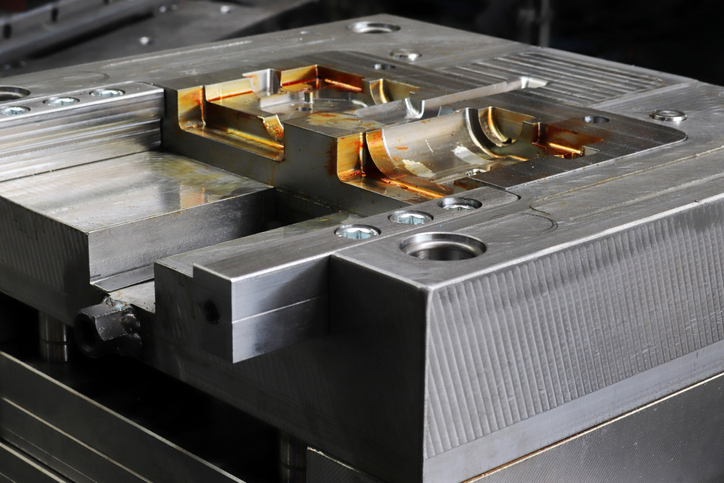

Injection molding is a widely used manufacturing process for producing high-quality, complex parts in large volumes. While EPDM can be injection molded, it requires specialized equipment and expertise to ensure a successful outcome. In this article, we will delve into the specifics of what makes EPDM a challenging material to work with and what measures can be taken to ensure successful injection molding.

Can You Injection Mold EPDM?

EPDM, or Ethylene Propylene Diene Monomer, is a synthetic rubber used in various industries due to its excellent resistance to heat, chemicals, and weathering. Injection molding is a popular manufacturing process, but can EPDM be injection molded? Let’s find out.

EPDM and Injection Molding

EPDM can be injection molded, but it requires special considerations due to its unique properties. First, it is important to choose the right injection molding machine and process. EPDM has a lower viscosity compared to other materials, so a machine with a higher injection pressure is necessary to achieve the desired flow rate.

Another important factor is the mold design. EPDM has a tendency to shrink more than other materials, so the mold must account for this by adding extra material to compensate for the shrinkage. In addition, the mold temperature must be carefully controlled to prevent warping and other defects.

The Benefits of Injection Molding EPDM

EPDM has several advantages when it comes to injection molding. One of the main benefits is its high thermal stability, which makes it ideal for applications that require resistance to heat and chemicals. It also has excellent weathering resistance, making it suitable for outdoor use.

Another benefit is its ability to be molded into complex shapes with high precision. Injection molding allows for intricate designs and tight tolerances, making it a cost-effective solution for high-volume production.

EPDM vs. Other Materials

EPDM has several advantages over other materials when it comes to injection molding. For example, EPDM has a higher resistance to heat and chemicals compared to other rubber materials such as natural rubber and SBR. It also has better weathering resistance compared to PVC and other plastics.

EPDM also has a longer lifespan compared to other materials, making it a more durable choice for applications that require long-term use. However, it is important to note that EPDM can be more expensive than other materials, so it is important to weigh the benefits against the cost.

Applications of Injection Molded EPDM

EPDM is used in a variety of applications, including automotive parts, electrical insulation, roofing membranes, and seals. Injection molding allows for the production of complex shapes and tight tolerances, making it ideal for applications that require high precision and durability.

EPDM seals are particularly popular due to their excellent weathering resistance and ability to maintain their elasticity over time. Injection molding also allows for the production of large quantities of seals at a low cost, making it a cost-effective solution for manufacturers.

Conclusion

In conclusion, EPDM can be injection molded, but it requires special considerations due to its unique properties. Choosing the right injection molding machine and mold design is crucial to achieve the desired flow rate and prevent defects. However, the benefits of EPDM, such as its high thermal stability and ability to be molded into complex shapes, make it a popular choice for various applications.

Frequently Asked Questions

Here are some common questions related to injection molding of EPDM:

Can EPDM be injection molded?

Yes, EPDM (ethylene propylene diene monomer) can be injection molded. It is a thermoset material that can be molded into various shapes and sizes. The injection molding process involves heating the EPDM material to a molten state and then injecting it into a mold cavity under high pressure.

EPDM is known for its excellent resistance to heat, weather, and ozone, making it a popular choice for automotive and construction applications. Injection molding is a cost-effective way to produce large quantities of EPDM parts with consistent quality and accuracy.

What are the benefits of injection molding EPDM?

Injection molding offers several benefits when it comes to molding EPDM:

- High production speed and efficiency

- Consistent part quality and accuracy

- Ability to mold complex shapes and geometries

- Low material waste and scrap

- Cost-effective for high-volume production runs

EPDM is a versatile material that can be used in a variety of industries, and injection molding is a popular method for producing EPDM parts due to its many advantages.

What are some common injection molding issues with EPDM?

Although EPDM is a highly durable material, it can still present some challenges when it comes to injection molding. Some common issues include:

- Sink marks or warping due to uneven cooling

- Flash or burrs on the parts

- Inconsistent part quality or color

- Difficulty in achieving tight tolerances

However, these issues can often be resolved by adjusting the molding process parameters, such as temperature, pressure, and cycle time, or by using specialized molding techniques, such as gas-assisted injection molding or two-shot molding.

What are some applications of EPDM injection molded parts?

EPDM injection molded parts are used in a variety of industries and applications, including:

- Automotive seals, gaskets, and weatherstripping

- Construction seals, roofing, and flashing

- Electronics and electrical connectors

- Appliances and household goods

- Medical and healthcare equipment

EPDM’s excellent resistance to heat, weather, and chemicals make it a reliable choice for parts that require durability and longevity.

What are some best practices for injection molding EPDM?

Here are some tips for achieving optimal results when injection molding EPDM:

- Use a high-quality EPDM material with consistent properties

- Ensure the mold is properly designed and vented

- Optimize the molding process parameters for the specific EPDM material and part design

- Monitor and adjust the process to avoid issues such as sink marks or flash

- Perform regular mold maintenance and cleaning to prevent buildup or damage

Following these best practices can help ensure that EPDM injection molding produces high-quality parts with minimal waste or defects.

In conclusion, injection molding of EPDM is a viable option for many manufacturers. The material’s unique properties, such as its excellent resistance to weathering, heat, and chemicals, make it an ideal choice for a wide range of applications.

However, it is essential to work with a skilled injection molding company that has experience working with EPDM. This will ensure that the material is properly processed and that the final product meets all necessary specifications.

Overall, if you’re looking for a durable, high-quality material for your injection molding needs, EPDM is definitely worth considering. With the right supplier and production process, you can create a product that is both reliable and long-lasting.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com