Table of Contents

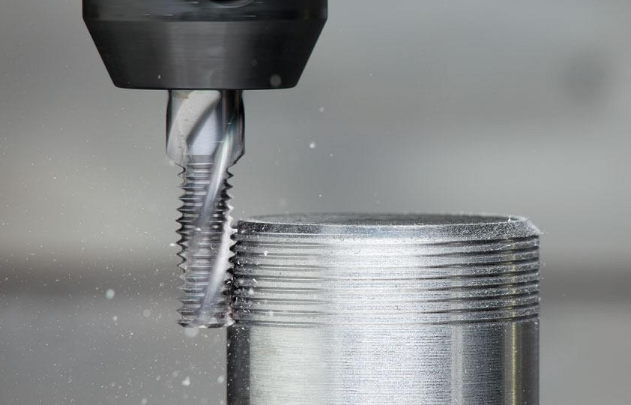

Thread cutting is a crucial operation in the manufacturing industry, and it requires precision and accuracy. Manual threading is a time-consuming and laborious process that can lead to errors. However, with the advancement in technology, CNC machines have made the thread cutting process efficient and accurate. The question that arises is, can you thread with a CNC machine? In this article, we will explore the capabilities of CNC machines in thread cutting and how they can benefit the manufacturing industry.

CNC machines can perform a wide range of operations, including drilling, milling, and cutting. However, thread cutting is a unique operation that requires a specific set of tools and techniques. With a CNC machine, thread cutting is possible, and it can produce precise and accurate results. In this article, we will delve into the details of how a CNC machine can thread and the advantages it provides over manual threading.

Can You Thread With a CNC Machine?

Threading is an essential process in manufacturing, and it involves creating helical grooves on the surface of a cylindrical workpiece. Traditionally, threading was done manually or with specialized machines, but with the advent of CNC machines, the process has become more efficient and accurate. However, many people are still skeptical about the ability of CNC machines to thread. Can you thread with a CNC machine? Let’s find out.

Understanding CNC Machines

CNC machines are computer-controlled manufacturing tools that can perform a range of operations, including milling, drilling, and cutting. The machines use specialized software to interpret design specifications and execute precise movements on the workpiece. CNC machines have become increasingly popular in manufacturing because they offer high precision, repeatability, and efficiency.

Benefits of CNC Machines for Threading

CNC machines can be highly effective for threading because they offer several advantages over traditional methods. First, CNC machines can thread at high speeds, which reduces production time and increases output. Second, CNC machines can maintain high accuracy and consistency, which is crucial in threading applications. Finally, CNC machines can be programmed to thread a wide range of materials, including metals, plastics, and composites.

Challenges of CNC Machines for Threading

While CNC machines offer several benefits for threading, there are also some challenges to consider. One challenge is the setup time required to program the machine for threading. In addition, CNC machines can be expensive to purchase and maintain, which may not be practical for small-scale operations. Finally, CNC machines require skilled operators who can program and operate the machines effectively.

Types of Threads That Can Be Made with CNC Machines

CNC machines can be used to make a wide range of thread types, including internal and external threads, single and multiple-start threads, and tapered and straight threads. The machine can be programmed to create threads with different pitches, depths, and angles, depending on the design specifications.

Internal and External Threads

Internal threads are threads that are cut into a hole, while external threads are threads that are cut onto the surface of a shaft or bolt. CNC machines can create both types of threads, which makes them highly versatile for threading applications.

Single and Multiple-Start Threads

Single-start threads have one continuous helix around the circumference of the workpiece, while multiple-start threads have two or more helices around the circumference. Multiple-start threads can be used to increase the thread engagement, which improves the strength of the joint.

Tapered and Straight Threads

Tapered threads have a gradually changing diameter along the length of the thread, while straight threads have a constant diameter. Tapered threads are commonly used in pipe fittings, while straight threads are used in bolts and screws.

CNC Machines vs. Traditional Threading Methods

While traditional threading methods have been used for many years, CNC machines offer several advantages over these methods.

Accuracy and Consistency

CNC machines offer high accuracy and consistency, which is crucial in threading applications. Traditional methods can be prone to human error, which can lead to inconsistencies in the thread dimensions.

Speed and Efficiency

CNC machines can thread at high speeds, which reduces production time and increases output. Traditional methods can be slower, especially when threading large or complex workpieces.

Versatility

CNC machines can be programmed to thread a wide range of materials, including metals, plastics, and composites. Traditional methods may be limited in the types of materials they can thread.

Conclusion

In conclusion, CNC machines can be highly effective for threading applications. While there are some challenges to consider, such as setup time and operator skill requirements, the benefits of CNC machines for threading outweigh the drawbacks. CNC machines offer high accuracy, speed, and versatility, which make them an attractive option for manufacturers looking to improve their threading processes.

Frequently Asked Questions

CNC machines are a popular tool for a variety of tasks, including threading. However, there are many questions surrounding the use of CNC machines for this purpose. Below are five frequently asked questions and answers regarding threading with a CNC machine.

Can you thread with a CNC machine?

Yes, it is possible to thread with a CNC machine. In fact, CNC machines are often used for threading because they can accurately and consistently cut threads. However, there are some important considerations to keep in mind when using a CNC machine for threading.

First, it is important to choose the right tooling for the job. Thread mills and single-point tools are common choices for threading with a CNC machine. It is also important to use the correct cutting speed and feed rate to ensure the best results. Additionally, the machine must be properly programmed to ensure that the thread is cut to the correct specifications.

What are the benefits of threading with a CNC machine?

There are several benefits to threading with a CNC machine. One of the main advantages is the accuracy and consistency that can be achieved. CNC machines can cut threads to precise specifications, ensuring a high-quality end product. Additionally, CNC machines can be programmed to cut threads quickly and efficiently, which can save time and increase productivity.

Another benefit of threading with a CNC machine is the versatility it offers. CNC machines can be used to cut threads in a variety of materials, including metals, plastics, and composites. This makes them a valuable tool for a wide range of industries, from automotive to aerospace.

What are the limitations of threading with a CNC machine?

While there are many benefits to threading with a CNC machine, there are also some limitations to keep in mind. One of the main limitations is the cost of the machine itself. CNC machines can be expensive to purchase and maintain, which may not be feasible for all businesses. Additionally, CNC machines require skilled operators to program and operate, which can be a challenge for some companies.

Another limitation of threading with a CNC machine is the size of the workpiece. CNC machines are typically designed to work with smaller to medium-sized parts, so larger workpieces may require a different approach to threading. Additionally, some materials may be more difficult to thread with a CNC machine, such as those that are prone to chip or break.

How do you program a CNC machine for threading?

Programming a CNC machine for threading requires a thorough understanding of the machine and the specifications of the thread being cut. First, the machine must be set up with the correct tooling, including the thread mill or single-point tool. The cutting speed and feed rate must also be determined based on the material being cut and the specifications of the thread.

Once the machine is set up and the tooling is in place, the operator must program the machine to cut the thread to the correct specifications. This involves inputting the thread pitch, diameter, and other relevant information into the machine’s control system. The operator must also set the depth of cut and the number of passes required to complete the thread.

What are some tips for threading with a CNC machine?

Threading with a CNC machine can be a complex process, but there are some tips that can help ensure success. One important tip is to choose the right tooling for the job. Thread mills and single-point tools are common choices for threading with a CNC machine, but the specific tool chosen will depend on the material being cut and the specifications of the thread.

Another tip is to use the correct cutting speed and feed rate. This will help ensure that the thread is cut accurately and efficiently. It is also important to keep the machine well-maintained and properly lubricated to prevent damage and ensure a longer lifespan. Finally, it is important to have a skilled operator who understands the machine and the threading process to ensure the best results.

In conclusion, threading with a CNC machine is not only possible but also highly efficient. With the use of specialized software and tools, a CNC machine can produce accurate and consistent threads that are essential in various industries. Whether you’re working with metal, wood, or plastic, a CNC machine can provide the precision and speed required for threading.

Moreover, threading with a CNC machine offers numerous advantages over traditional methods. It eliminates the need for manual labor, reducing the risk of errors and enhancing productivity. Additionally, CNC machines are programmable, allowing for custom threading designs and patterns that are difficult to achieve manually. This makes them a valuable asset in the manufacturing industry, especially for high-volume production.

In summary, threading with a CNC machine is not only feasible but also a smart choice for those seeking accuracy, consistency, and speed. As technology advances, we can expect to see more innovations in CNC machining, making it an even more versatile and valuable tool in various industries.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com