Table of Contents

- Freequently Asked Questions

- Can gray flexible conduit be used for CNC machines?

- What are the benefits of using gray flexible conduit for CNC machines?

- What size of gray flexible conduit should be used for CNC machines?

- How can gray flexible conduit be installed on a CNC machine?

- What are the alternatives to using gray flexible conduit for CNC machines?

Are you planning to set up a CNC machine and wondering if gray flexible conduit could be a suitable option for cable protection? Well, the answer is not a straightforward yes or no. There are several factors to consider before deciding if gray flexible conduit is the right choice for your CNC machine.

Firstly, it is important to understand the purpose of the conduit and the environment in which the CNC machine will operate. In this article, we will explore the pros and cons of using gray flexible conduit for cable protection in a CNC machine setup, and help you make an informed decision. So, let’s get started!

Can You Use Gray Flexible Conduit for CNC Machine?

When it comes to CNC machines, choosing the right conduit is an important decision that can affect the overall performance and longevity of the machine. Gray flexible conduit is a popular choice for many applications, but can it be used for CNC machines? In this article, we will explore the pros and cons of using gray flexible conduit for CNC machines and help you make an informed decision.

What is Gray Flexible Conduit?

Gray flexible conduit is a type of conduit that is made from a flexible material such as PVC or nylon. It is used to protect electrical wiring and cables from damage and to provide a safe and secure pathway for them to travel through. Gray flexible conduit is often used in industrial and commercial applications where there is a need for flexibility and durability.

Gray flexible conduit is available in different sizes and lengths and can be used in a variety of applications such as HVAC systems, lighting installations, and machinery. It is also commonly used in outdoor applications where exposure to the elements can cause damage to electrical wiring and cables.

Benefits of Gray Flexible Conduit

Gray flexible conduit has several benefits that make it a popular choice for many applications. Some of the benefits include:

- Flexibility: Gray flexible conduit can be bent and shaped to fit around corners and curves, making it a great choice for installations in tight spaces.

- Durability: Gray flexible conduit is made from tough, durable materials that can withstand harsh environments and resist damage from impact and abrasion.

- Easy Installation: Gray flexible conduit is easy to install and can be cut to the desired length with a simple tool such as a pair of scissors or a knife. It can also be secured with a variety of fittings and accessories.

Disadvantages of Gray Flexible Conduit

While gray flexible conduit has many benefits, it also has some disadvantages that should be considered before using it in a CNC machine. Some of the disadvantages include:

- Heat Resistance: Gray flexible conduit is not as heat-resistant as other types of conduit such as metallic conduit. This can be a problem in applications where there is a high risk of heat damage to electrical wiring and cables.

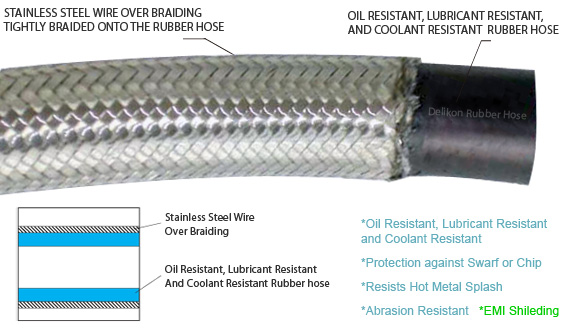

- EMI Interference: Gray flexible conduit can cause electromagnetic interference (EMI) which can affect the performance of sensitive equipment such as CNC machines. This can lead to errors and decreased accuracy.

- Chemical Resistance: Some chemicals can damage gray flexible conduit, which can compromise the integrity of the conduit and lead to electrical issues.

Using Gray Flexible Conduit for CNC Machines

Gray flexible conduit can be used for CNC machines, but it is important to consider the specific requirements of the machine before making a decision. Some CNC machines require conduit that is heat-resistant, EMI-resistant, and chemical-resistant, which may rule out gray flexible conduit as a viable option.

If gray flexible conduit is to be used for a CNC machine, it should be carefully installed and secured to prevent any movement or damage to the electrical wiring and cables. It is also important to use fittings and accessories that are compatible with gray flexible conduit to ensure a secure and reliable installation.

Gray Flexible Conduit vs. Metallic Conduit

One alternative to gray flexible conduit is metallic conduit, which has several advantages for CNC machines. Metallic conduit is more heat-resistant than gray flexible conduit, which makes it a better choice for applications where there is a risk of heat damage. It is also EMI-resistant, which can help to prevent interference with sensitive equipment such as CNC machines.

However, metallic conduit is less flexible than gray flexible conduit, which can make it more difficult to install in tight spaces. It is also heavier and more expensive than gray flexible conduit, which can make it less cost-effective for some applications.

Conclusion

In conclusion, gray flexible conduit can be used for CNC machines, but it is important to consider the specific requirements of the machine before making a decision. Gray flexible conduit has several benefits such as flexibility, durability, and easy installation, but it also has some disadvantages such as heat resistance, EMI interference, and chemical resistance.

If gray flexible conduit is to be used for a CNC machine, it should be carefully installed and secured to prevent any movement or damage to the electrical wiring and cables. It is also important to consider alternatives such as metallic conduit, which may be a better choice for some applications.

Freequently Asked Questions

Here are some frequently asked questions about using gray flexible conduit for CNC machine:

Can gray flexible conduit be used for CNC machines?

Yes, gray flexible conduit can be used for CNC machines. This type of conduit is commonly used in industrial applications and is designed to protect wires and cables from damage. It is flexible and can be easily installed in tight spaces, making it a popular choice for CNC machines.

When selecting a gray flexible conduit for CNC machines, it is important to choose one that is rated for the appropriate temperature and is resistant to oil and chemicals. This will help ensure that the conduit provides adequate protection and does not degrade over time.

What are the benefits of using gray flexible conduit for CNC machines?

Using gray flexible conduit for CNC machines offers several benefits. Firstly, it provides protection for the wires and cables, ensuring that they do not become damaged or tangled. Secondly, it can help to reduce the risk of electrical fires by containing any sparks that may occur. Finally, it can make it easier to maintain the CNC machine as it allows for easy access to the wires and cables.

Gray flexible conduit is also resistant to corrosion, which can be a problem in industrial environments. It is also easy to install and can be cut to the required length, making it a cost-effective solution for protecting wires and cables.

What size of gray flexible conduit should be used for CNC machines?

The size of gray flexible conduit that should be used for CNC machines will depend on the size of the wires and cables that need to be protected. It is important to choose a conduit that is large enough to accommodate the wires and cables without being too bulky or cumbersome.

It is also important to consider the length of the conduit that will be required. If the CNC machine is located in a large workspace, a longer conduit may be needed to ensure that all of the wires and cables are adequately protected.

How can gray flexible conduit be installed on a CNC machine?

Gray flexible conduit can be installed on a CNC machine in a few simple steps. Firstly, the conduit should be cut to the required length using a pair of wire cutters. It should then be threaded through the appropriate holes and secured in place using cable ties or clamps.

It is important to ensure that the conduit is not too tight or too loose as this can cause damage to the wires and cables. Once the conduit is in place, the wires and cables can be inserted and connected to the appropriate components.

What are the alternatives to using gray flexible conduit for CNC machines?

There are several alternatives to using gray flexible conduit for CNC machines. One option is to use metal conduit, which offers a higher level of protection but can be more difficult to install. Another option is to use cable trays, which can be used to hold the wires and cables in place without the need for conduit.

However, gray flexible conduit is still a popular choice for CNC machines due to its flexibility, ease of installation, and cost-effectiveness. It is important to consider the specific needs of the CNC machine when selecting a conduit or alternative solution.

In conclusion, using gray flexible conduit for CNC machines is possible, but it’s important to ensure that the conduit meets the necessary safety standards for the application. The flexibility and durability of the conduit make it a popular choice for CNC machines, but it’s essential to choose a conduit that is rated for the specific environment and conditions of the machine.

When selecting a gray flexible conduit for your CNC machine, it’s important to consider factors such as temperature range, chemical resistance, and resistance to abrasion and impact. Additionally, it’s crucial to ensure that the conduit is installed properly to prevent any damage or safety hazards.

Overall, gray flexible conduit can be a suitable option for CNC machines, but it’s essential to choose a conduit that is designed for the specific needs of your machine and to follow proper installation guidelines. With the right conduit in place, you can help ensure the safety and reliability of your CNC machine for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com