Table of Contents

CNC machines have revolutionized the manufacturing industry by automating the production process, resulting in greater efficiency and accuracy. However, there is a common misconception that every G-code run by a CNC machine is saved, and this can lead to confusion and potential errors in production.

In this article, we will explore the truth behind whether CNC machines save each G-code run and the implications of this for manufacturing. We will also discuss the importance of proper G-code management and how it can improve the overall productivity of CNC machines. So, let’s dive in and discover the facts about CNC machines and G-code saving.

Do CNC Machines Save Each Gcode Ran?

Yes, CNC machines can save each Gcode ran. The Gcode program is stored in the machine’s memory, and it can be accessed and run whenever needed. This feature is especially useful in mass production, as the same program can be used repeatedly without having to re-enter the code. However, it is important to note that the machine’s memory capacity will limit the number of programs that can be saved.

Do CNC Machines Save Each Gcode Ran?

CNC machines have revolutionized the manufacturing industry by automating the production process. These machines have become an essential tool for businesses that need to produce high-quality parts with precision and speed. But one question that often comes up when it comes to CNC machines is whether they save each Gcode ran. Let’s take a closer look at this topic.

What is Gcode?

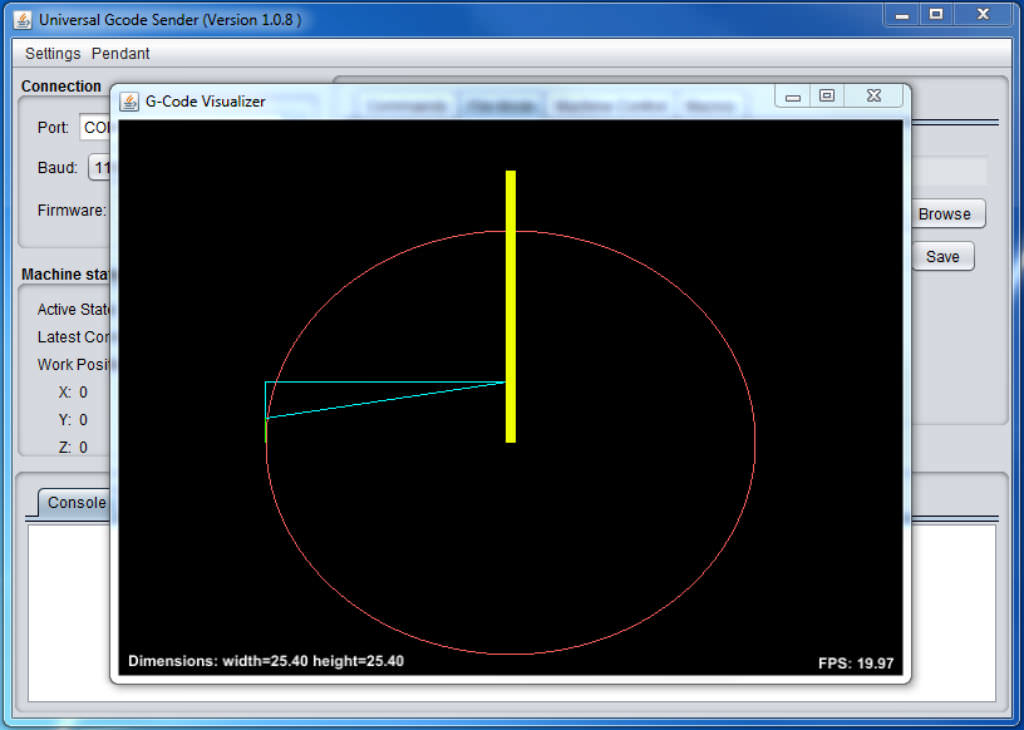

Gcode is a programming language used to control CNC machines. It is a series of commands that tell the machine what to do and how to do it. The Gcode is written by a programmer and then loaded into the CNC machine. The machine reads the code and executes the commands to produce the desired part.

Benefits of Gcode

One of the benefits of using Gcode is that it allows for precise control over the manufacturing process. The programmer can specify the exact movements and machining operations required to produce the part. This precision leads to a higher level of accuracy and repeatability, which is essential for producing high-quality parts.

How Does Gcode Work?

Gcode is made up of a series of commands that tell the machine what to do. These commands include movements, such as moving the machine’s cutting tool along a particular path, and machining operations, such as cutting or drilling. The Gcode also includes information about the machine’s speed, feed rate, and other parameters.

Benefits of Saving Each Gcode Ran

Saving each Gcode ran has several benefits. First, it allows for the easy replication of parts. If a company needs to produce the same part again, they can simply load the Gcode and run the program. Second, it provides a record of the manufacturing process, which can be useful for quality control and troubleshooting. Finally, it allows for the optimization of the manufacturing process over time. By analyzing the Gcode, a company can identify areas for improvement and make changes to the process to increase efficiency and reduce waste.

Gcode vs. Other Programming Languages

Gcode is not the only programming language used to control CNC machines. Other languages, such as CAM software, can also be used. However, Gcode is the most commonly used language, and it has several advantages. First, it is a simple language that is easy to learn and use. Second, it is compatible with most CNC machines, which makes it a versatile option. Finally, it allows for precise control over the manufacturing process, which is essential for producing high-quality parts.

Do CNC Machines Save Each Gcode Ran?

The answer to this question is not straightforward. Some CNC machines do save each Gcode ran, while others do not. It depends on the specific machine and the settings used.

Types of CNC Machines

There are two types of CNC machines: those with non-volatile memory and those without. CNC machines with non-volatile memory can save each Gcode ran. Non-volatile memory is a type of memory that retains data even when the power is turned off. This means that the Gcode will be saved even if the machine is turned off.

CNC Machines without Non-Volatile Memory

CNC machines without non-volatile memory cannot save each Gcode ran. These machines rely on volatile memory, which means that the data is lost when the power is turned off. In this case, the Gcode will need to be reloaded into the machine each time the program is run.

Conclusion

In conclusion, whether CNC machines save each Gcode ran depends on the specific machine and its settings. CNC machines with non-volatile memory can save each Gcode, while those without cannot. Saving each Gcode ran has several benefits, including easy replication of parts, a record of the manufacturing process, and the optimization of the manufacturing process over time. Gcode is a simple language that allows for precise control over the manufacturing process and is the most commonly used language for CNC machines.

Frequently Asked Questions

Here are some common questions about whether CNC machines save each Gcode ran.

Do CNC machines save each Gcode ran?

Yes, CNC machines have the capability to save each Gcode ran. This is because the Gcode is essentially a program that instructs the machine on how to move and cut. Once the program has been executed, it can be saved onto a memory device, such as a USB drive or hard drive, so that it can be retrieved and ran again in the future.

Additionally, some CNC machines have a feature that automatically saves each Gcode ran into a log file. This log file can be useful for troubleshooting any issues that may arise during the machining process.

How can I save Gcode on my CNC machine?

There are a few ways to save Gcode on a CNC machine. One way is to save the program onto a USB drive and then plug the USB drive into the machine’s controller. From there, you can access the program and run it as needed.

Another way to save Gcode is to use the machine’s internal memory. Some machines have the ability to store programs directly onto the controller, either through a network connection or by using a memory card. This can be a convenient option if you frequently use the same programs on your machine.

Can I edit saved Gcode programs?

Yes, saved Gcode programs can be edited. Most CNC machines have a built-in editor that allows you to make changes to the program. You can also use external software to edit Gcode programs on your computer and then transfer the edited program back to the machine.

However, it’s important to be careful when editing Gcode programs, as any mistakes can lead to costly errors or damage to the machine. It’s recommended that you make a backup of the original program before making any changes.

How long can Gcode programs be saved on a CNC machine?

The length of time that Gcode programs can be saved on a CNC machine depends on the capacity of the machine’s memory. Some machines have a limited amount of memory, which means that programs may need to be periodically deleted to make room for new ones.

However, many CNC machines now have large amounts of memory, which can store hundreds or even thousands of programs. Some machines even have the capability to store programs on a cloud-based server, which can be accessed from anywhere with an internet connection.

Are there any risks associated with saving Gcode programs on a CNC machine?

There are a few risks associated with saving Gcode programs on a CNC machine. One risk is that the machine’s memory could become corrupted or damaged, which could result in the loss of saved programs. To mitigate this risk, it’s important to regularly back up your programs onto an external device.

Another risk is that someone could access the machine and delete or modify programs without authorization. To prevent this, it’s recommended that you secure your machine with passwords and limit access to authorized personnel only.

In conclusion, CNC machines have revolutionized the manufacturing industry by providing accuracy and precision in production. The use of G-code has made it easier to program and control these machines, but does it save each G-code ran? The answer is not straightforward, as it depends on various factors such as the complexity of the part being produced, the type of material used, and the programming skills of the operator.

However, it is evident that the use of CNC machines and G-code has significantly reduced the time and effort required to produce parts compared to traditional methods. The automation of the production process has also reduced the chances of errors and increased the consistency of the final product. This has led to increased productivity and profitability in many manufacturing industries.

In conclusion, while it may not be possible to measure the exact savings for each G-code ran, the use of CNC machines and G-code has undoubtedly improved the efficiency and quality of production. As technology continues to advance, we can expect further improvements in the manufacturing industry, leading to even more significant savings and benefits.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com