Table of Contents

Have you ever wondered how intricate metal shapes are cut with precision? The answer lies in the world of CNC plasma cutters. These machines have revolutionized the manufacturing industry by allowing for the quick and accurate cutting of metal materials.

Using a combination of computer programming, electricity, and gas, a CNC plasma cutter can cut through a variety of metals with ease. In this article, we’ll explore the inner workings of a CNC plasma cutter and how it has transformed the way metal fabrication is done. So, buckle up and get ready to dive into the fascinating world of CNC plasma cutters.

How a CNC Plasma Cutter Works?

If you’re in the metalworking industry, you’ve likely heard about CNC plasma cutters. These machines use plasma torches to cut through metal quickly and efficiently. But how exactly does a CNC plasma cutter work? In this article, we’ll take a closer look at the technology behind these powerful machines.

What is a CNC Plasma Cutter?

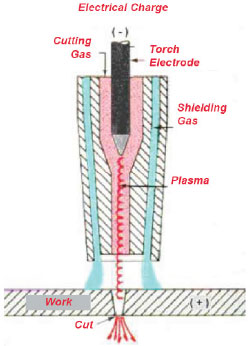

A CNC plasma cutter is a machine that uses a plasma torch to cut through metal. The machine is controlled by a computer, which allows for precise cuts and shapes. The plasma torch uses a high-temperature ionized gas to melt through metal, creating a clean and precise cut.

To use a CNC plasma cutter, the operator first designs the part they want to cut using computer-aided design (CAD) software. This design is then converted into a machine-readable format, which is loaded onto the CNC plasma cutter’s computer. The operator then positions the metal to be cut underneath the plasma torch and initiates the cutting process.

The Plasma Cutting Process

Once the cutting process has been initiated, the plasma torch moves along the metal, melting and cutting through it as it goes. The high-temperature plasma gas reacts with the metal, causing it to melt and create a clean cut. The machine’s computer controls the speed and movement of the plasma torch, ensuring that the cut is precise and accurate.

The plasma cutting process is incredibly fast and efficient. It can cut through metal thicknesses ranging from 0.5mm to 50mm and can cut through a variety of metals, including steel, aluminum, and copper.

The Benefits of Using a CNC Plasma Cutter

There are several benefits to using a CNC plasma cutter in metalworking. Here are just a few:

1. Precision: CNC plasma cutters are incredibly precise, allowing for complex shapes and cuts to be made with ease.

2. Speed: The plasma cutting process is incredibly fast, making it an efficient way to cut through metals.

3. Versatility: CNC plasma cutters can cut through a variety of metals, making them a versatile tool in metalworking.

4. Cost-effective: CNC plasma cutters are cost-effective compared to other cutting methods, making them a popular choice in the metalworking industry.

CNC Plasma Cutters vs. Other Cutting Methods

There are several cutting methods available in metalworking, including laser cutting and waterjet cutting. Here’s how CNC plasma cutters compare:

1. Laser cutting: Laser cutting is incredibly precise but is often more expensive than plasma cutting. It is also less effective when cutting through thick metals.

2. Waterjet cutting: Waterjet cutting is incredibly precise and versatile but is often slower than plasma cutting. It is also more expensive than plasma cutting.

3. CNC plasma cutting: CNC plasma cutting is fast, precise, and cost-effective. It is ideal for cutting through thick metals and is a popular choice in the metalworking industry.

Conclusion

CNC plasma cutters are an essential tool in the metalworking industry. They use plasma torches to cut through metal quickly and efficiently, allowing for precise cuts and shapes. The benefits of using a CNC plasma cutter include precision, speed, versatility, and cost-effectiveness. Compared to other cutting methods, CNC plasma cutting is often the best choice for cutting through thick metals.

Frequently Asked Questions

Here are some common questions and answers about how a CNC plasma cutter works:

How does a CNC plasma cutter work?

A CNC plasma cutter works by using an electrically charged torch to cut through a variety of conductive materials. The torch creates a high-temperature plasma arc that melts the material and blows away the molten metal with compressed gas. The CNC (computer numerical control) system controls the torch and the cutting table, using programmed instructions to create precise cuts in the material.

What materials can a CNC plasma cutter cut?

A CNC plasma cutter can cut through a variety of materials, such as steel, aluminum, brass, copper, and other conductive metals. It can also cut through non-metal materials such as wood, plastic, and even glass, as long as they are conductive enough to be melted by the plasma arc.

How accurate is a CNC plasma cutter?

A CNC plasma cutter is very accurate, with the ability to make cuts within a thousandth of an inch. The CNC system uses precise measurements and cutting instructions to ensure that each cut is accurate, even when cutting complex shapes or patterns. However, accuracy can also depend on factors such as the quality of the cutting table and the skill of the operator.

What are the advantages of using a CNC plasma cutter?

One of the main advantages of using a CNC plasma cutter is its ability to make precise cuts quickly and efficiently. It can also cut through a variety of materials, making it a versatile tool for many industries. Additionally, the CNC system allows for easy programming and automation, reducing the need for manual labor and increasing productivity.

What are some common uses for a CNC plasma cutter?

A CNC plasma cutter is commonly used in industries such as metal fabrication, automotive manufacturing, and construction. It can be used to create parts for machinery, cut metal for building structures, and even produce intricate artwork. It is also popular among DIY enthusiasts and hobbyists who use it for custom metal fabrication projects.

In conclusion, a CNC plasma cutter is a highly efficient cutting machine that uses plasma to cut through various materials such as metal, wood, and plastic. With its advanced technology, the machine is able to produce precise cuts with minimal waste, making it a popular choice among manufacturers and fabricators.

One of the key advantages of a CNC plasma cutter is its versatility. Unlike traditional cutting methods, the machine can cut through a wide range of materials with ease, allowing for greater flexibility in production. Additionally, the machine’s automation capabilities allow for increased efficiency and accuracy, reducing the risk of errors and improving overall productivity.

Overall, the CNC plasma cutter is a powerful and innovative tool that has revolutionized the manufacturing and fabrication industries. With its ability to produce high-quality cuts quickly and efficiently, it has become an essential part of any modern production process. Whether you’re working with metal, wood, or plastic, a CNC plasma cutter is the perfect solution for all your cutting needs.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com