Table of Contents

Additive manufacturing, also known as 3D printing, has revolutionized the way we create objects. Using digital designs and materials such as plastics, metals, and even food, additive manufacturing can produce complex shapes and structures that traditional manufacturing methods cannot. But how does it work? In this article, we will explore the process of additive manufacturing and the various technologies used to create objects layer by layer.

From the initial design to the finished product, additive manufacturing involves a series of steps that require precision and attention to detail. Whether you are a seasoned engineer or a curious hobbyist, understanding the fundamentals of additive manufacturing can help you unlock its full potential. So, let’s dive in and explore the fascinating world of 3D printing!

How Additive Manufacturing Works?

Additive manufacturing, also known as 3D printing, is a rapidly growing technology that is transforming the way we manufacture products. It is a process of creating three-dimensional objects from a digital file by adding layers of material one layer at a time. In this article, we will explore the basics of additive manufacturing and how it works.

Step 1: Creating a 3D Model

The first step in additive manufacturing is to create a 3D model using computer-aided design (CAD) software. The software allows designers to create virtual models of the object they want to produce. The 3D model is then saved in a file format that can be read by a 3D printer.

Once the 3D model is created, the software slices it into thin layers. This process is essential as it determines the thickness of each layer that the 3D printer will use to build the object.

Step 2: Preparing the 3D Printer

After the 3D model is created and sliced, it is time to prepare the 3D printer. The 3D printer needs to be loaded with the appropriate material for the object being produced. The material can be in the form of a filament, powder, or liquid.

The 3D printer also needs to be calibrated to ensure that it is printing accurately. The calibration process involves setting the print bed to the correct height, adjusting the temperature of the print head, and ensuring that the material is feeding correctly into the printer.

Step 3: Printing the Object

Once the 3D printer is prepared, it is time to start printing the object. The 3D printer begins by laying down the first layer of material. It does this by melting or fusing the material together using a heated print head.

After the first layer is complete, the printer moves up slightly, and the next layer is added on top of the first. This process continues until the object is complete, layer by layer.

The Benefits of Additive Manufacturing

Additive manufacturing has several benefits over traditional manufacturing methods. One of the most significant benefits is the ability to produce complex shapes and designs that are difficult or impossible to create with traditional manufacturing methods.

Additive manufacturing also allows for rapid prototyping, which can speed up the product development process. It also reduces waste as only the necessary amount of material is used to create the object, reducing costs.

Additive Manufacturing vs. Traditional Manufacturing

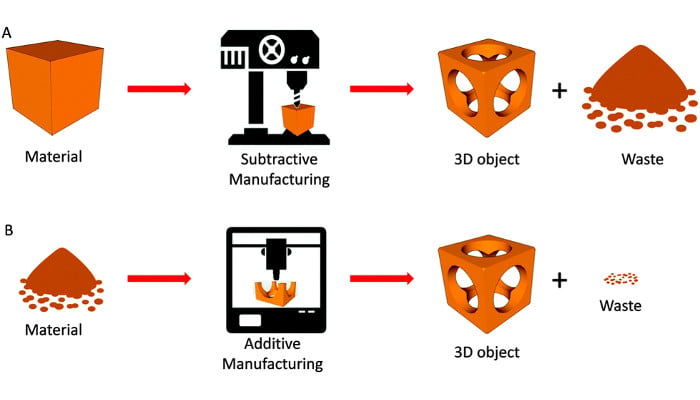

Traditional manufacturing methods involve subtracting material from a block or piece of material to create a shape. This can be a time-consuming process, and it can result in a lot of waste material.

Additive manufacturing, on the other hand, adds material layer by layer, only using the necessary amount of material to create the object. This reduces waste and can be a more cost-effective method of manufacturing.

The Future of Additive Manufacturing

Additive manufacturing is still a relatively new technology, but it is rapidly growing and evolving. As the technology continues to advance, it is likely that we will see more widespread adoption in industries such as aerospace, healthcare, and automotive.

In the future, we may also see the development of new materials that can be used in additive manufacturing, which will further expand the possibilities of this technology.

Conclusion

Additive manufacturing is an innovative technology that is changing the way we manufacture products. By creating objects layer by layer, additive manufacturing allows for the production of complex shapes and designs that are difficult or impossible to create with traditional manufacturing methods.

As the technology continues to advance, we can expect to see more widespread adoption in a variety of industries. Additive manufacturing has the potential to revolutionize the manufacturing process, leading to increased efficiency, reduced waste, and lower costs.

Frequently Asked Questions

Additive manufacturing, also known as 3D printing, is a revolutionary technology that is changing the way we manufacture products. This technology has the potential to transform industries and make manufacturing more efficient and cost-effective.

What is Additive Manufacturing?

Additive manufacturing is a process of creating three-dimensional objects by adding layers of material one by one. This is in contrast to traditional manufacturing methods, where objects are created by removing material through cutting or drilling. Additive manufacturing is also known as 3D printing because it uses a digital file to create physical objects layer by layer.

The process starts with a digital file that is created using computer-aided design (CAD) software. The file is then uploaded to the 3D printer, which reads the file and creates the object by adding layers of material one by one. The material used can vary and can include plastic, metal, and even food.

How does Additive Manufacturing work?

Additive manufacturing works by building an object layer by layer. The process begins with a digital model of the object you want to create. This model is sliced into thin layers using specialized software. The 3D printer then reads these layers and builds up the object by depositing material layer by layer.

The material used in additive manufacturing can vary depending on the application. Some common materials include plastics, metals, ceramics, and composites. The 3D printer uses a variety of techniques to deposit the material, including extrusion, powder bed fusion, and vat photopolymerization.

What are the Benefits of Additive Manufacturing?

Additive manufacturing has many benefits over traditional manufacturing methods. One of the main benefits is that it allows for the creation of complex geometries that would be impossible to produce using traditional methods. This means that additive manufacturing can be used to create parts that are lighter, stronger, and more efficient than those created using traditional methods.

Another benefit of additive manufacturing is that it can be more cost-effective than traditional manufacturing methods, especially for small production runs. This is because additive manufacturing does not require expensive tooling or setup costs, and it can be done using a single machine.

What are the Limitations of Additive Manufacturing?

While additive manufacturing has many benefits, it also has some limitations. One of the main limitations is the size of the objects that can be created. Most 3D printers have a limited build volume, which means that they can only create objects up to a certain size. This can be a problem for larger objects, which may need to be created in multiple pieces and then assembled.

Another limitation of additive manufacturing is the material properties. While additive manufacturing can create parts that are lighter and stronger than those created using traditional methods, the materials used can have limitations in terms of temperature resistance, chemical resistance, and other properties. This means that some applications may not be suitable for additive manufacturing.

What are the Applications of Additive Manufacturing?

Additive manufacturing has many applications across a wide range of industries. One of the main applications is in prototyping and product development. Additive manufacturing allows designers to quickly create and test new designs without the need for expensive tooling or molds.

Other applications of additive manufacturing include creating replacement parts for machinery, creating custom medical implants, and even creating food. Additive manufacturing has the potential to transform many industries and is likely to become an increasingly important part of the manufacturing process in the years to come.

In conclusion, additive manufacturing is a revolutionary technology that is transforming the way we produce and manufacture products. It has tremendous potential to improve efficiency and reduce costs in various industries, from automotive to aerospace, medical to fashion. With its flexibility, speed, and accuracy, it is no wonder why it is gaining popularity among manufacturers around the world.

As we have seen, additive manufacturing involves building objects layer by layer, using digital models and 3D printers. It allows for greater design freedom and customization, as well as the ability to create complex shapes and structures that would be impossible with traditional manufacturing methods. This technology has opened up new possibilities in product design and innovation, enabling faster prototyping and shorter time-to-market.

In the coming years, we can expect to see even more advancements in additive manufacturing, as researchers and engineers continue to refine the technology and explore new applications. From bioprinting organs to printing entire houses, the possibilities are endless. Additive manufacturing is truly a game-changer, and its impact on the manufacturing industry is only just beginning.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com