Table of Contents

Are you curious about the level of detail that can be achieved with a CNC plasma cutter? Look no further! In this article, we will explore the capabilities of CNC plasma cutting technology and how it allows for intricate and precise designs to be cut with ease.

With the ability to cut through various metals and alloys, CNC plasma cutting has become a popular choice in manufacturing and fabrication industries. But what sets it apart from other cutting methods is its precision and level of detail. From intricate geometrical shapes to custom designs, CNC plasma cutters can create flawless edges and smooth curves that are difficult to achieve with traditional cutting methods. Join us as we delve deeper into the world of CNC plasma cutting and uncover its secrets to achieving precision and detail.

A CNC plasma cutter can achieve very high levels of detail, especially when compared to other cutting methods. The precision of the cut is dependent on a variety of factors, including the size of the plasma arc, the speed of the cutting process, and the accuracy of the CNC machine. With the right settings and a skilled operator, a CNC plasma cutter can create intricate designs and precise cuts on a wide range of materials.

How Detail Can You Get With a CNC Plasma?

CNC plasma cutting is a computer-controlled method of cutting metal that has revolutionized the metal fabrication industry. With this technology, it is possible to cut intricate shapes and designs with precision, speed, and accuracy. But how detailed can you get with a CNC plasma? Let’s find out.

Understanding CNC Plasma Cutting

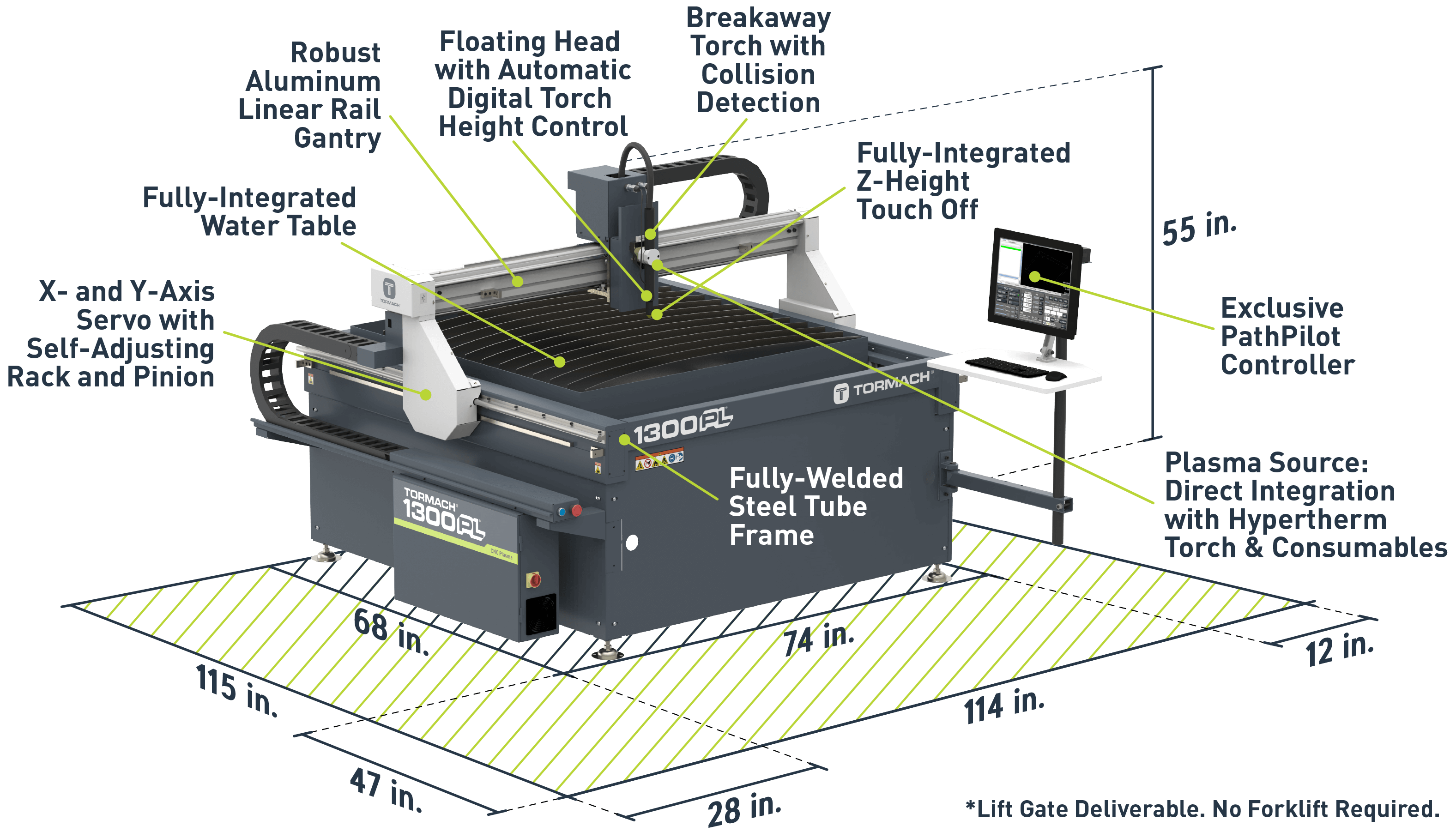

CNC plasma cutting uses a plasma torch to cut metal sheets into precise shapes and sizes. The plasma torch is a handheld device that is connected to a computer-controlled cutting table. The cutting table moves the metal sheet in the X and Y directions, while the plasma torch moves in the Z direction, cutting the metal with a high-velocity jet of ionized gas.

The Benefits of CNC Plasma Cutting

CNC plasma cutting offers several benefits over traditional cutting methods. First, it is faster and more accurate than manual cutting. Second, it can cut through a wide range of materials, including steel, aluminum, and copper. Third, it produces clean and precise cuts, which reduces the need for secondary operations like grinding and polishing.

The Versatility of CNC Plasma Cutting

CNC plasma cutting is a versatile method of cutting metal. It can be used to cut simple shapes like circles and squares, as well as complex designs like logos and decorative patterns. With the right software and programming, CNC plasma cutting can produce intricate designs with precise angles and curves.

The Limitations of CNC Plasma Cutting

While CNC plasma cutting is a powerful technology, it does have some limitations. One of the main limitations is the thickness of the material that can be cut. CNC plasma cutting is best suited for materials that are 1 inch thick or less. Additionally, CNC plasma cutting is not ideal for cutting materials that are highly reflective or conductive, as these materials can interfere with the plasma torch.

The vs. Other Cutting Methods

Compared to other cutting methods like waterjet cutting and laser cutting, CNC plasma cutting is generally less expensive and faster. However, it may not be as precise as laser cutting, which can produce cuts with a tolerance of 0.001 inches or less. Additionally, waterjet cutting can cut through thicker materials than CNC plasma cutting.

The Importance of Choosing the Right CNC Plasma Cutting Service

When choosing a CNC plasma cutting service, it is important to consider factors like experience, equipment, and customer service. Look for a company that has a proven track record of delivering high-quality cuts, and that uses the latest equipment and software. Also, choose a company that is responsive to your needs and that offers competitive pricing.

Conclusion

In conclusion, CNC plasma cutting is a powerful method of cutting metal that can produce intricate designs with precision and accuracy. While it does have some limitations, it is a versatile and cost-effective cutting method that is ideal for a wide range of applications. When choosing a CNC plasma cutting service, be sure to choose a company that has the experience and expertise to deliver the high-quality cuts you need.

Freequently Asked Questions

Here are some frequently asked questions about the level of detail that can be achieved with a CNC plasma cutting machine:

What is a CNC plasma cutting machine?

A CNC plasma cutting machine is a computer-controlled cutting machine that uses a plasma torch to cut metal. The machine can cut through a variety of metals, including steel, aluminum, brass, and copper. The machine is used in a variety of industries, including construction, automotive, and manufacturing.

The machine uses a computer program to control the movement of the plasma torch. The program tells the machine where to cut and how deep to cut. The machine can cut intricate designs and shapes with high precision.

How detailed can a CNC plasma cut?

A CNC plasma cutting machine can cut with a high level of detail. The machine can cut intricate designs and shapes with high precision. The level of detail that can be achieved depends on the size of the plasma torch and the thickness of the metal being cut.

The smaller the plasma torch, the more detailed the cut can be. The machine can cut designs as small as a quarter of an inch. The thickness of the metal being cut also affects the level of detail. Thicker metal requires a larger plasma torch and may not be able to achieve the same level of detail as thinner metal.

What are some examples of detailed cuts that can be made with a CNC plasma?

A CNC plasma cutting machine can make a variety of detailed cuts, including intricate shapes, logos, and text. The machine can also cut out detailed designs for metal art and sculptures.

The machine can cut out shapes with sharp corners and tight curves. It can also create beveled edges and weld-preparation cuts. The machine can cut through metal with high precision, creating clean, smooth cuts.

What materials can be cut with a CNC plasma?

A CNC plasma cutting machine can cut a variety of metals, including steel, aluminum, brass, and copper. The machine can also cut other materials, such as wood and plastic, with the appropriate plasma torch and setup.

The machine can cut through thick materials, up to several inches thick, depending on the size of the plasma torch. The machine can also cut through a variety of metal alloys and grades.

What are the benefits of using a CNC plasma cutting machine for detailed cuts?

A CNC plasma cutting machine offers several benefits for making detailed cuts. The machine can cut with high precision, creating clean, smooth cuts. The machine is computer-controlled, allowing for precise control over the cutting process.

The machine is also efficient, with a high cutting speed and low cost per cut. The machine can cut a variety of materials, making it a versatile tool for a variety of industries. The machine can also cut intricate designs and shapes, making it ideal for creating custom metal parts and pieces.

In conclusion, the level of detail that can be achieved with a CNC plasma machine is truly remarkable. From intricate designs to precise cuts, this technology has revolutionized the metal fabrication industry.

With the ability to work with a variety of metals and thicknesses, CNC plasma machines offer unparalleled precision and accuracy, making them a popular choice among manufacturers and DIY enthusiasts alike.

Whether you’re creating custom metal art or manufacturing complex industrial parts, a CNC plasma machine can help you achieve the level of detail you need to bring your vision to life. So why not take advantage of this cutting-edge technology and see for yourself just how detailed and precise your designs can be?

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com