Table of Contents

If you’re a newbie in the milling CNC world, you may be wondering how to turn on tool speed. It’s a crucial aspect to understand because it determines the quality and speed of your milling work. In this article, we’re going to explore the different ways you can turn on tool speed in milling CNC and make the most out of it.

From adjusting the RPM to tweaking the feed rates, there are several ways to turn on tool speed in milling CNC. Whether you’re working on a small or large project, understanding how to optimize tool speed can help you achieve better results and save time. So, let’s get started and dive into the world of milling CNC tool speed!

To turn on tool speed in milling CNC, follow these steps:

- Press the “Settings” button on the control panel.

- Select “Tool Management” from the menu.

- Choose “Tool Speed” and enter the desired speed.

- Press “Save” to apply the changes.

How to Turn on Tool Speed in Milling CNC?

If you’re new to the world of CNC milling, you may be wondering how to adjust the tool speed on your machine. The good news is that with a few simple steps, you’ll be able to control the tool speed and optimize your milling process for efficiency and precision.

Step 1: Access the Milling Program

Before you can adjust the tool speed, you need to access the milling program on your CNC machine. This typically involves selecting the appropriate program from a menu or inputting the program code manually.

Once you’ve accessed the program, you’ll need to navigate to the section that controls the tool speed. This section may be labeled “spindle speed” or “feed rate,” depending on your machine’s make and model.

Step 2: Choose the Tool Speed

Once you’ve located the tool speed control section, you can adjust the speed to your desired setting. This is typically measured in revolutions per minute (RPM) and can range from a few hundred to several thousand, depending on the material you’re milling and the type of tool you’re using.

When selecting a tool speed, it’s important to consider a variety of factors, including the material’s hardness, the tool’s diameter, and the desired surface finish. In general, higher tool speeds are better for softer materials, while lower speeds are more appropriate for harder materials.

Step 3: Monitor the Tool Speed

Once you’ve adjusted the tool speed, it’s important to monitor it throughout the milling process. This will allow you to ensure that the speed remains consistent and that the machine is operating as expected.

If you notice any fluctuations in the tool speed or unusual sounds or vibrations, it may be necessary to adjust the speed or inspect the machine for issues.

The Benefits of Optimizing Tool Speed in Milling CNC

By optimizing the tool speed in your milling CNC process, you can achieve a variety of benefits, including:

- Improved precision and accuracy

- Reduced tool wear and tear

- Increased efficiency and productivity

- Enhanced surface finish quality

In addition, by understanding how to control the tool speed, you can make more informed decisions about the milling process and optimize your results for a range of materials and applications.

Tool Speed vs. Feed Rate: What’s the Difference?

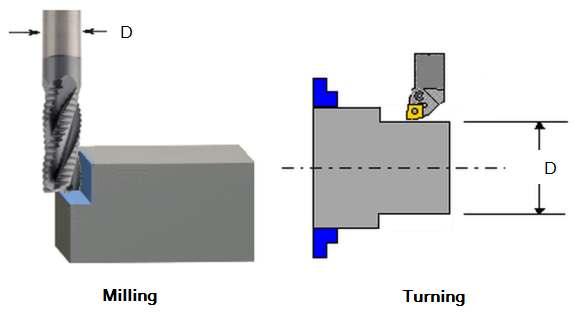

While tool speed and feed rate are both important factors in CNC milling, they refer to different aspects of the process.

Tool speed refers to the rotational speed of the tool itself, while feed rate refers to the rate at which the tool moves through the material being milled. Both factors can impact the quality of the finished product and should be carefully controlled for optimal results.

By adjusting both the tool speed and feed rate as needed, you can achieve a precise and efficient milling process that meets your specific requirements.

The Bottom Line

By following these simple steps and taking the time to understand the importance of tool speed in milling CNC, you can optimize your milling process for improved efficiency, precision, and quality. Whether you’re a seasoned CNC professional or just starting out, this knowledge will serve you well in achieving your milling goals.

Frequently Asked Questions

Here are some commonly asked questions about turning on tool speed in milling CNC.

How do I turn on tool speed in milling CNC?

The first step to turning on tool speed in milling CNC is to access the machine’s control panel. Once you have access to the control panel, look for the tool speed setting. This setting is typically located in the machine’s settings menu. Once you have located the tool speed setting, you can adjust it to your desired speed. Be sure to refer to your machine’s user manual for specific instructions on how to adjust the tool speed.

It is also important to note that some CNC machines may require additional software or programming in order to adjust the tool speed. If you are unsure about how to adjust the tool speed on your CNC machine, consult with a professional or contact the manufacturer for guidance.

Why is tool speed important in milling CNC?

Tool speed is an important factor in milling CNC because it affects the quality and efficiency of the machining process. If the tool speed is too slow, the milling process will take longer and may result in poor quality cuts. On the other hand, if the tool speed is too high, it can cause excessive wear and tear on the machine’s cutting tools. Finding the right tool speed for your specific milling application is crucial for achieving optimal results.

Additionally, adjusting the tool speed can also help to reduce the risk of tool breakage or damage. By setting the tool speed to the appropriate level, you can ensure that the cutting tools are able to handle the demands of the milling process without becoming damaged or broken.

What factors should I consider when adjusting tool speed in milling CNC?

When adjusting tool speed in milling CNC, there are several factors that you should consider. First, you should consider the material that you are milling. Different materials may require different tool speeds in order to achieve optimal results. Additionally, you should consider the size and shape of the cutting tools you are using, as well as the depth and speed of the milling process itself.

It is also important to consider the type of CNC machine you are using. Some machines may have specific requirements or limitations when it comes to adjusting tool speed. Be sure to consult with your machine’s user manual or a professional for guidance on how to adjust the tool speed for your specific machine and milling application.

What are some common mistakes to avoid when adjusting tool speed in milling CNC?

One common mistake to avoid when adjusting tool speed in milling CNC is setting the speed too high or too low. This can result in poor quality cuts or damage to the machine’s cutting tools. It is important to find the right balance when adjusting tool speed in order to achieve optimal results.

Another mistake to avoid is failing to consider the specific requirements of your machine and milling application. Different machines and materials may have different tool speed requirements. Additionally, failing to properly maintain your machine’s cutting tools can also lead to issues with tool speed and overall milling performance.

How can I troubleshoot tool speed issues in milling CNC?

If you are experiencing issues with tool speed in milling CNC, there are several troubleshooting steps you can take. First, check to ensure that the tool speed setting is properly adjusted according to your machine’s user manual. If the setting is correct, check the machine’s cutting tools for damage or wear and replace them if necessary.

You can also try adjusting the milling process itself, such as reducing the cutting depth or slowing down the feed rate. If none of these steps resolve the tool speed issues, consult with a professional or contact the manufacturer for further assistance.

In conclusion, turning on the tool speed in milling CNC is an essential step in achieving a precise and efficient machining process. By adjusting the tool speed, you can ensure that the cutting tool is operating at the optimal speed for the material being machined. This will result in a higher quality finish, reduced tool wear, and faster machining times.

To turn on the tool speed in milling CNC, you need to access the machine’s control panel and locate the spindle speed control. Once you have located the spindle speed control, you can adjust the speed using the machine’s software or physical controls. It is essential to ensure that you are using the correct spindle speed for the material and tool being used to avoid causing damage to either.

Overall, turning on the tool speed in milling CNC is a simple but critical step that can have a significant impact on the quality and efficiency of your machining process. By following the correct procedures and ensuring that you are using the appropriate speed, you can achieve accurate and consistent results every time.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com