CNC lathes are an essential component of the modern manufacturing industry. These machines use computer numerical control (CNC) to automate the process of turning raw materials into finished products. One of the most important parts of a CNC lathe is the turret, which holds and rotates the cutting tools used to shape the material.

The CNC lathe turret is a complex and highly engineered component that plays a critical role in the machining process. Understanding how it works can help you appreciate the precision and efficiency of modern manufacturing and the vital role that CNC technology plays in it. In this article, we will explore the inner workings of a CNC lathe turret and how it enables the production of high-quality, precision machined parts.

Understanding the Functioning of a CNC Lathe Turret

What is a CNC Lathe Turret?

A CNC lathe turret is a component used in a lathe machine that holds and indexes the cutting tools. It is responsible for changing the tools and bringing them into the cutting position. This automated process is efficient and fast, allowing for a high level of precision in the manufacturing process.

The turret is typically mounted on the lathe carriage and can hold several tools at once, allowing for a quick tool change and reducing the time required for the manufacturing process. The CNC lathe turret is a critical component of the lathe machine and plays a vital role in the manufacturing process.

How Does a CNC Lathe Turret Work?

The CNC lathe turret operates through a series of movements that allow for efficient tool changes. The turret is typically controlled by a computer program and is automated to move the tools into position. Here is a brief overview of how the CNC lathe turret works:

– The turret is loaded with several tools, each of which is mounted in a holder.

– When a tool change is required, the lathe spindle is stopped, and the turret is moved into position.

– The current tool holder is rotated out of position and replaced with the new tool holder.

– The turret is then rotated back into position, and the spindle is restarted to continue the manufacturing process.

The entire process is automated and can be completed in seconds, allowing for a high level of efficiency in the manufacturing process.

The Benefits of a CNC Lathe Turret

There are several benefits to using a CNC lathe turret in the manufacturing process. These include:

– Increased efficiency: The automated process of the CNC lathe turret allows for quick tool changes and reduces the time required for the manufacturing process.

– Improved precision: The CNC lathe turret allows for a high level of precision in the manufacturing process, ensuring that the finished product meets the required specifications.

– Reduced labor costs: The automated process of the CNC lathe turret reduces the need for manual labor in the manufacturing process, reducing labor costs.

CNC Lathe Turret Vs. Manual Lathe Turret

While a manual lathe turret can perform similar functions to a CNC lathe turret, there are several key differences between the two. Here are some of the differences:

– Automation: The CNC lathe turret is fully automated, while a manual lathe turret requires manual labor to change the tools.

– Efficiency: The CNC lathe turret is more efficient than a manual lathe turret, allowing for quick tool changes and reducing the time required for the manufacturing process.

– Precision: The CNC lathe turret allows for a higher level of precision in the manufacturing process than a manual lathe turret.

Conclusion

In conclusion, the CNC lathe turret is an essential component in the lathe machine, allowing for quick tool changes and a high level of precision in the manufacturing process. The automated process of the CNC lathe turret offers several benefits, including increased efficiency, improved precision, and reduced labor costs. While a manual lathe turret can perform similar functions, the CNC lathe turret offers several advantages, making it the preferred choice for many manufacturing processes.

Frequently Asked Questions

If you are interested in the workings of a CNC lathe turret, you may have some questions about how it operates. Here are some frequently asked questions about CNC lathe turrets that may help you understand them better.

What is a CNC lathe turret?

A CNC lathe turret is a component of a computer numerical control (CNC) lathe machine that holds tooling for cutting and shaping material. CNC lathe turrets can hold multiple tools, allowing for complex operations to be performed without the need for manual tool changes. The turret is mounted on the lathe carriage and can be rotated to bring different tools into position for cutting.

The CNC lathe turret is an essential component of modern manufacturing and allows for precise and efficient cutting of various materials. The ability to switch between tools quickly and easily makes CNC lathe turrets highly versatile and ideal for producing complex parts.

How does a CNC lathe turret work?

A CNC lathe turret operates by rotating a disc that holds the various cutting tools. The disc is mounted on a shaft that is positioned parallel to the lathe spindle. The turret is driven by a motor that rotates the shaft, bringing the desired cutting tool into position for cutting.

The CNC lathe turret is controlled by the CNC machine’s computer, which sends signals to the motor to rotate the turret and bring the appropriate tool into position. The computer also controls the cutting speed, depth, and other parameters, ensuring precise and efficient cutting.

What are the advantages of a CNC lathe turret?

One of the main advantages of a CNC lathe turret is its ability to hold multiple cutting tools, allowing for complex operations to be performed without the need for manual tool changes. This saves time and increases productivity, making CNC lathe turrets ideal for high-volume production.

CNC lathe turrets also offer precise and repeatable cutting, making them ideal for producing complex parts with tight tolerances. They can also be programmed to perform multiple operations, such as drilling, milling, and turning, further increasing their versatility.

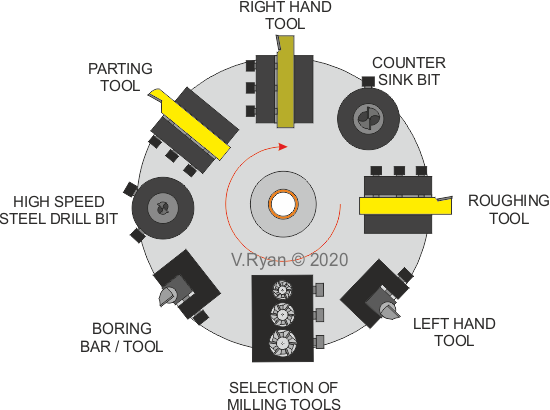

What types of tools can a CNC lathe turret hold?

CNC lathe turrets can hold a variety of cutting tools, including turning tools, boring tools, drilling tools, and threading tools. The specific tools used depend on the material being cut and the desired shape and finish of the part.

CNC lathe turrets can also hold special tools, such as live tools, which can perform additional operations, such as milling or drilling, while the material is still on the lathe. This further increases the efficiency and versatility of CNC lathe turrets.

How do you maintain a CNC lathe turret?

Proper maintenance is essential for keeping a CNC lathe turret in good working order. Regular cleaning and lubrication of the turret and its components can help prevent wear and damage.

It is also important to regularly check and replace any worn or damaged parts, such as bearings or belts, to ensure the turret operates correctly. Finally, following the manufacturer’s recommended maintenance schedule can help prolong the life of the CNC lathe turret and ensure it continues to operate at peak efficiency.

In conclusion, a CNC lathe turret is a remarkable precision tool that revolutionizes the manufacturing industry. Its ability to automate the machining process and produce high-quality parts consistently has made it an indispensable part of modern machining.

The turret works by holding various cutting tools that can be rotated into the machining position as needed. This allows for a wide range of machining operations to be performed without the need for manual tool changes, saving time and increasing efficiency.

Overall, the CNC lathe turret is a testament to the ingenuity and innovation of the machining industry. As technology continues to advance, it will undoubtedly continue to play a vital role in the manufacturing world, helping to drive progress and shape the future of production.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com