Table of Contents

- How Does CNC Software Work?

- 1. The Basics of CNC Software

- 2. The Role of CNC Software in Manufacturing

- 3. Benefits of CNC Software

- 4. CNC Software Vs. Traditional Manufacturing Methods

- 5. Types of CNC Software

- 6. CNC Software and 3D Printing

- 7. Future of CNC Software

- 8. Limitations of CNC Software

- 9. Training for CNC Software

- 10. Conclusion

- Freequently Asked Questions

CNC software is the backbone of modern manufacturing industries. It is responsible for the precision and accuracy of the machines that produce the products we use every day. But how exactly does CNC software work, and what makes it so essential to the manufacturing process?

At its core, CNC software is a set of instructions that tell a computer-controlled machine how to move and position its cutting tools. These instructions are written in a language that the machine can understand, allowing it to execute complex tasks with incredible speed and accuracy. In this article, we’ll take a closer look at how CNC software works and explore its role in modern manufacturing.

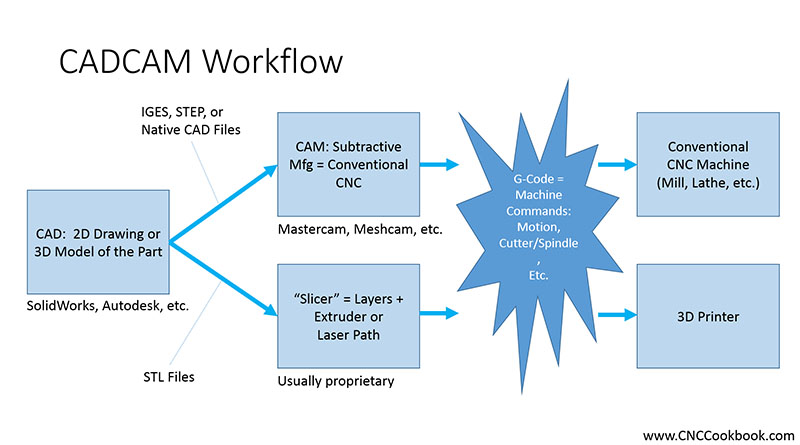

CNC (Computer Numerical Control) software works by converting a design created in a computer-aided design (CAD) program into a language that can be understood by the CNC machine. This language, called G-code, tells the machine how to move its tools and cut the material. The software also allows the user to control the speed, direction, and depth of the cuts. CNC software can be customized for different types of machines and materials, allowing for precise and efficient cutting.

How Does CNC Software Work?

CNC (Computer Numerical Control) software is an integral part of modern manufacturing. CNC software controls the operation of machines that use computerized mathematical data to guide their movements. The software is critical in the manufacturing process as it ensures precision, speed, accuracy, and repeatability of tasks. CNC software works by controlling the machine’s movements, which are pre-programmed into the software.

1. The Basics of CNC Software

CNC software is designed to provide instructions to the machine on how to move and cut materials. The software reads the coded instructions and translates them into movements for the machine. CNC software is used to control various machines, including lathes, mills, routers, and plasma cutters. The software uses a programming language called G-code that tells the machine how to move the tool.

CNC software provides a graphical interface that allows users to input the instructions. The user can create the design using CAD (Computer-Aided Design) software, which is then translated into G-code by the CNC software. The software then sends the G-code to the machine, which follows the instructions to create the design.

2. The Role of CNC Software in Manufacturing

CNC software has revolutionized the manufacturing industry. It has made it possible to produce complex designs with high precision and accuracy. The software has made it easier to produce parts with tight tolerances, reducing the need for manual labor and increasing productivity.

The software provides a level of automation that was previously impossible. It can perform repetitive tasks with high accuracy, reducing the risk of errors. CNC software is also flexible and can be programmed to produce different designs, making it ideal for mass production.

3. Benefits of CNC Software

CNC software has several benefits, including increased productivity, accuracy, and precision. The software allows manufacturers to produce parts with a high level of consistency, reducing the need for manual labor. CNC software also reduces the risk of errors, ensuring that parts are produced to the highest standards.

The software is also cost-effective, as it reduces the need for manual labor and increases productivity. CNC software is also flexible, allowing manufacturers to produce different designs without the need for retooling.

4. CNC Software Vs. Traditional Manufacturing Methods

CNC software has several advantages over traditional manufacturing methods. The software provides a level of precision and accuracy that is impossible with manual labor. CNC software also reduces the risk of errors, ensuring that parts are produced to the highest standards.

Traditional manufacturing methods are often time-consuming and require a high level of manual labor. CNC software reduces the need for manual labor, making the manufacturing process faster and more efficient. Additionally, CNC software can produce complex designs that are impossible with traditional methods.

5. Types of CNC Software

There are several types of CNC software, including CAD/CAM software, CAM software, and CNC controller software. CAD/CAM software is used to design parts and create the G-code that is used to control the machine. CAM software is used to create toolpaths and optimize the machining process. CNC controller software is used to control the machine’s movements and execute the G-code.

Each type of software has different functions and is designed for different stages of the manufacturing process. CAD/CAM software is used in the design phase, while CAM software is used in the production phase. CNC controller software is used during the manufacturing process to control the machine’s movements.

6. CNC Software and 3D Printing

CNC software is also used in 3D printing. 3D printing uses additive manufacturing, which builds parts layer by layer. CNC software is used to control the printer’s movements and ensure that the parts are printed with precision and accuracy.

The software is used to create the design, which is then translated into G-code. The G-code is used to control the printer’s movements, ensuring that the parts are printed with high precision and accuracy.

7. Future of CNC Software

The future of CNC software is bright, with new technologies and innovations being developed every day. The software is becoming more advanced, with new features being added to improve productivity, accuracy, and precision.

CNC software is also becoming more user-friendly, with graphical interfaces that are easy to use. The software is also becoming more flexible, allowing manufacturers to produce different designs without the need for retooling.

8. Limitations of CNC Software

CNC software has some limitations, including the need for a skilled operator. The software requires a skilled operator to program the machine and ensure that the parts are produced to the required standards. The software is also limited by the machine’s capabilities, with some machines being limited in terms of the materials they can work with.

9. Training for CNC Software

Training is essential for anyone who wants to use CNC software. The software requires a skilled operator who can program the machine and ensure that the parts are produced to the required standards. Training is available for operators, with many community colleges and technical schools offering courses in CNC programming.

10. Conclusion

CNC software is an essential part of modern manufacturing. The software provides a level of precision and accuracy that is impossible with manual labor. It also reduces the risk of errors, ensuring that parts are produced to the highest standards. CNC software is cost-effective and flexible, allowing manufacturers to produce different designs without the need for retooling. With new technologies and innovations being developed every day, the future of CNC software is bright.

Freequently Asked Questions

CNC or Computer Numerical Control software is an essential tool used in machining processes. It is a type of software that helps in controlling and managing the various functions of machines. In this article, we will discuss how CNC software works and answer some of the most commonly asked questions about it.

1. How does CNC software work?

CNC software works by converting a design or blueprint into instructions that a machine can understand. These instructions are then sent to the machine’s controller, which reads them and executes the necessary actions. The software uses a programming language that is specific to the machine being used.

The CNC software controls the movements of the machine’s various components, such as the spindle, cutting tool, and workpiece. It also manages the speed and feed rate of the machine, ensuring that the desired results are achieved accurately and efficiently.

2. What are the benefits of using CNC software?

One of the main benefits of using CNC software is that it allows for precise and accurate machining. The software can control the machine’s movements with an accuracy of up to 0.0001 inches, which is not possible with manual machining. This level of precision ensures that the finished product meets the required specifications.

CNC software also allows for increased productivity and efficiency. The software can automate many of the machining processes, which reduces the need for manual labor and improves the speed of production. This, in turn, can lead to cost savings for the manufacturer.

3. What types of machines can be controlled using CNC software?

CNC software can be used to control a wide range of machines, including lathes, mills, routers, plasma cutters, and more. The software is specific to each type of machine and is designed to work with the machine’s unique capabilities and functions.

The software can be used to perform a variety of machining operations, including drilling, cutting, milling, and turning. It can also be used to create complex shapes and designs that would be difficult or impossible to achieve with manual machining.

4. How is CNC software programmed?

CNC software is typically programmed using a computer-aided design (CAD) program. The CAD program is used to create a digital design or blueprint of the part or product that needs to be machined. The design is then exported to the CNC software, which converts it into machine-readable instructions.

The CNC software can also be programmed manually using a programming language such as G-code. G-code is a language that is specific to CNC machines and is used to control the machine’s movements and functions.

5. Is CNC software difficult to learn?

Learning CNC software can be challenging, especially for those who have no experience with programming or machining. However, most CNC software comes with user-friendly interfaces and tutorials that make it easier to learn. Many manufacturers also offer training programs and support to help users get started with the software.

With practice and experience, users can become proficient in using CNC software and can create complex designs and products with ease. It is important to note that different types of CNC software may have different learning curves, so it is important to choose software that is appropriate for your skill level and needs.

In conclusion, CNC software is an essential tool in the manufacturing industry, enabling machines to operate with precision and accuracy. The software works by converting designs created in CAD software into numerical code that the machine can understand. This code controls the movement of the machine’s cutting tools, allowing it to create the desired product.

With the use of CNC software, manufacturers can produce complex and intricate designs that would otherwise be impossible to create by hand. The software also allows for faster production times and reduces the risk of errors or mistakes that can occur with manual machining.

Overall, CNC software is a game-changer in the manufacturing industry, providing greater efficiency, accuracy, and flexibility in the production process. Its continued development and innovation will undoubtedly lead to even greater advancements in the future.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com