Table of Contents

- Frequently Asked Questions

- How many CNC machines are needed for a solar panel factory?

- What is the role of CNC machines in a solar panel factory?

- How do CNC machines improve the efficiency of a solar panel factory?

- What are some of the factors that affect the number of CNC machines needed in a solar panel factory?

- What are the benefits of using CNC machines in a solar panel factory?

Solar energy has been gaining popularity in recent years as a clean and sustainable source of power. With the rise in demand for solar panels, manufacturers are looking for ways to increase their production efficiency. One of the key factors that determine this efficiency is the number of CNC machines per solar panel factory.

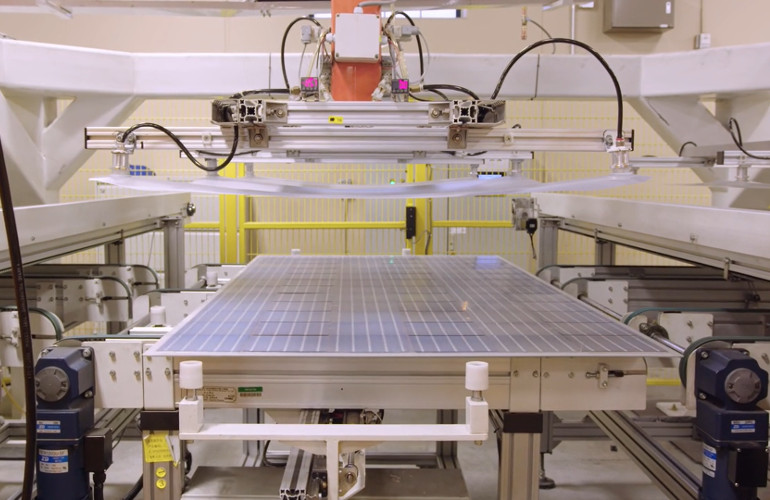

CNC machines play a crucial role in the manufacturing process of solar panels. They are used to cut and shape the panels into the desired size and shape. Therefore, it is essential for solar panel factories to have the optimal number of CNC machines to meet their production demands. In this article, we will explore the ideal number of CNC machines required for a solar panel factory to operate efficiently.

The number of CNC machines required for a solar panel factory depends on its size and production capacity. Generally, a small factory may require 2-3 CNC machines, while a large factory may need 10 or more. However, the exact number of CNC machines also depends on the type of solar panels being manufactured and the level of automation in the production process.

How Many CNC Machines Per Solar Panel Factory?

If you’re looking to start a solar panel factory, one of the most important considerations is the number of CNC machines you’ll need to meet your production targets. CNC machines are essential for precision cutting and shaping of solar panel components, and the number of machines required will depend on a range of factors, including the size of your factory and the level of automation you’re aiming for. In this article, we’ll explore some of the key factors that can help you determine how many CNC machines you’ll need for your solar panel factory.

1. Factory Size

The size of your factory will be one of the primary factors influencing the number of CNC machines you’ll need. A larger factory will typically require more machines to keep up with demand. One way to determine the number of machines needed is to calculate the total square footage of your factory and divide that number by the amount of space each CNC machine requires.

Another consideration is the layout of your factory. If you’re planning to use a more compact layout, you may be able to get away with fewer machines. However, if you’re aiming for a more open layout, you may need more machines to cover the increased space.

2. Production Capacity

The production capacity of your solar panel factory is another key factor to consider when determining the number of CNC machines needed. If you’re planning to produce a high volume of solar panels, you’ll likely need more machines to keep up with demand.

It’s important to keep in mind that the production capacity of your CNC machines will also be a factor. Some machines may be able to produce parts more quickly than others, which can impact the number of machines needed for your factory.

3. Level of Automation

The level of automation you’re aiming for will also play a role in determining the number of CNC machines needed for your solar panel factory. A highly automated factory may require fewer machines overall, as the machines will be able to perform multiple tasks and operate more efficiently.

However, a less automated factory may require more machines to compensate for the increased manual labor required. It’s important to consider the costs and benefits of automation when deciding on the number of machines needed for your factory.

4. Material Types

The types of materials used in your solar panel production will also impact the number of CNC machines needed. For example, if you’re using thicker materials, you may need heavier-duty machines to handle the cutting and shaping. On the other hand, if you’re using thinner materials, you may be able to get away with lighter machines.

It’s important to consider the specific materials you’ll be using in your solar panel production when determining the number of CNC machines needed.

5. Machine Features

The specific features of your CNC machines can also impact the number of machines needed for your solar panel factory. For example, if you’re planning to produce complex shapes and designs, you may need machines with more advanced cutting and shaping capabilities.

It’s important to consider the specific features you’ll need when selecting your CNC machines, as this can impact both the number of machines needed and the overall efficiency of your factory.

6. Maintenance and Downtime

Another factor to consider when determining the number of CNC machines needed for your solar panel factory is maintenance and downtime. Machines will inevitably require maintenance and repairs over time, and this downtime can impact your overall production capacity.

It’s important to factor in the potential downtime for each machine when determining the number of machines needed for your factory. You may also want to consider having backup machines on hand to minimize downtime in the event of a breakdown.

7. Budget

Of course, budget is also a key consideration when determining the number of CNC machines needed for your solar panel factory. CNC machines can be a significant investment, and you’ll need to balance your production needs with your available budget.

It’s important to research the costs of CNC machines carefully and select machines that offer the right balance of features, quality, and affordability for your needs.

8. Benefits of CNC Machines

Despite the significant investment required, CNC machines offer a range of benefits for solar panel factories. CNC machines offer precise cutting and shaping, which can improve the quality and consistency of your solar panels. They also offer increased efficiency and speed, which can help you meet your production targets more quickly.

By investing in the right number of CNC machines for your factory, you can enjoy these benefits and improve the overall profitability of your solar panel production.

9. CNC Machines vs. Manual Labor

While CNC machines offer significant benefits, it’s also important to consider the potential costs and benefits of manual labor. Depending on your production needs and budget, you may be able to achieve your production targets with a combination of CNC machines and manual labor.

It’s important to carefully consider the costs and benefits of each option when selecting the number of CNC machines needed for your factory.

10. Conclusion

Determining the number of CNC machines needed for your solar panel factory is a complex process that requires careful consideration of a range of factors. By taking into account your factory size, production capacity, level of automation, material types, machine features, maintenance and downtime, budget, and more, you can select the right number of machines to meet your needs.

With the right number of CNC machines in place, you can enjoy the benefits of improved quality, efficiency, and profitability in your solar panel production.

Frequently Asked Questions

Here are some commonly asked questions regarding the number of CNC machines required in a solar panel factory.

How many CNC machines are needed for a solar panel factory?

The number of CNC machines required for a solar panel factory depends on the size of the factory and the production capacity. Generally, a small solar panel factory may require only a few CNC machines, whereas a larger factory may require several dozen or even hundreds of machines.

CNC machines are essential for the manufacturing process of solar panels, as they are used to create the precise cuts and shapes needed for the panels. The number of machines needed will also depend on the types of solar panels being produced and the complexity of the manufacturing process.

What is the role of CNC machines in a solar panel factory?

CNC machines are used to create the precise cuts, shapes, and holes needed for the various components of a solar panel. They are also used for drilling, milling, and routing tasks that require high precision and accuracy.

Without CNC machines, it would be impossible to produce solar panels that meet the exact specifications required for efficient and reliable performance. CNC machines also help to reduce waste and improve efficiency in the manufacturing process, leading to cost savings and increased productivity.

How do CNC machines improve the efficiency of a solar panel factory?

CNC machines are computer-controlled and can perform tasks with a high degree of precision and accuracy. This means that the manufacturing process can be streamlined, reducing the time and resources needed to produce each solar panel.

Additionally, CNC machines can operate continuously, 24 hours a day, without the need for breaks or rest. This increases the overall productivity of the factory and helps to ensure that production targets are met. CNC machines also help to reduce waste and improve quality control, leading to further improvements in efficiency.

What are some of the factors that affect the number of CNC machines needed in a solar panel factory?

The number of CNC machines needed for a solar panel factory will depend on several factors, including the size of the factory, the production capacity, and the types of solar panels being produced.

Other factors that may affect the number of CNC machines needed include the level of automation in the factory, the complexity of the manufacturing process, and the availability of skilled workers to operate the machines. In general, a larger factory with a higher production capacity will require more CNC machines than a smaller factory with lower production levels.

What are the benefits of using CNC machines in a solar panel factory?

Using CNC machines in a solar panel factory offers several benefits, including increased precision and accuracy, improved efficiency, and reduced waste. CNC machines also help to improve quality control and reduce the risk of errors or defects in the manufacturing process.

Additionally, CNC machines can operate continuously, 24 hours a day, without the need for breaks or rest, leading to increased productivity and output. Finally, the use of CNC machines can help to reduce labor costs and improve profitability for the solar panel factory.

In conclusion, the number of CNC machines required per solar panel factory depends on various factors. The size of the factory, the production capacity, and the level of automation all play a significant role in determining the number of CNC machines needed.

It is important to note that CNC machines are essential for the production of high-quality and precise solar panels. Without these machines, the manufacturing process can become time-consuming, inefficient, and prone to errors.

Investing in the right number of CNC machines can increase production capacity, reduce production costs, and improve the overall quality of the solar panels. Therefore, it is crucial for solar panel factories to carefully evaluate their production needs and invest in the appropriate number of CNC machines to ensure efficient and cost-effective production.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com