Table of Contents

- How Much Can You Make With a CNC Machine?

- Frequently Asked Questions

- What is the average income of a CNC machine operator?

- Can you make money with a CNC machine at home?

- What are the factors that affect the profitability of a CNC machine business?

- What are some examples of profitable CNC machine businesses?

- What are some tips for starting a profitable CNC machine business?

CNC machines are among the most popular manufacturing tools in the modern age. From producing precision parts to engraving delicate designs, the possibilities are endless. But the question on everyone’s mind is, how much money can you make with a CNC machine? In this article, we will explore the earning potential of CNC machines and the factors that can affect your income.

Whether you’re an entrepreneur looking to start a business or a hobbyist seeking a new challenge, understanding the earning potential of a CNC machine is crucial. With the right skills, equipment, and business strategy, you can turn your CNC machine into a profitable venture. So, let’s dive into the world of CNC machines and explore the possibilities of making money with this state-of-the-art technology.

The amount of money you can make with a CNC machine depends on various factors, such as the type of machine, materials used, and the complexity of the design. On average, CNC machine operators in the United States earn around $18 per hour, while experienced operators can earn up to $30 per hour. Additionally, owning a CNC machine can also provide opportunities for starting a business and generating income through selling custom products or services.

How Much Can You Make With a CNC Machine?

If you are considering investing in a CNC machine, one of the most important questions you might have is about the earning potential. CNC machines are versatile tools that can be used to create a wide range of products, and the amount of money you can make with them will depend on several factors.

Factors that Affect Your Earnings

Several factors can impact how much you can make with a CNC machine. Some of the most significant include:

1. Type of CNC Machine

Different types of CNC machines are designed for different purposes. Some are best suited for woodworking, while others excel at cutting metal. The type of machine you choose will determine the kind of products you can create and the materials you can work with.

2. Quality of the Machine

Higher-quality CNC machines generally come with a higher price tag, but they also offer greater precision and reliability. This can translate into higher-quality products and faster production times, which can increase your earning potential.

3. Your Skill Level

Your experience and skill level with CNC machines can also impact your earnings. The more you know about programming, tooling, and material selection, the more efficiently you can use your machine to create high-quality products.

Examples of CNC Machine Earnings

While the amount you can earn with a CNC machine will depend on the factors mentioned above, there are some general guidelines that can give you an idea of what to expect. Here are some examples:

1. Woodworking

If you are using a CNC machine for woodworking, you can expect to earn anywhere from $50 to $200 per hour. This will depend on the complexity of the design, the size of the project, and the materials used.

2. Metalworking

For metalworking projects, you can earn anywhere from $75 to $250 per hour. This will depend on the type of metal used, the complexity of the design, and the size of the project.

3. Prototyping

If you are using your CNC machine for prototyping, you can earn anywhere from $50 to $100 per hour. This will depend on the complexity of the design and the materials used.

Benefits of Using a CNC Machine

Using a CNC machine can offer several benefits that can help increase your earning potential. Some of these benefits include:

1. Precision

CNC machines offer unparalleled precision that can help you create high-quality products with accuracy and consistency.

2. Efficiency

CNC machines can work faster and more efficiently than manual methods, which can help you complete projects more quickly and increase your earning potential.

3. Versatility

CNC machines can be used to create a wide range of products, from simple parts to intricate designs. This versatility can help you expand your business and increase your earning potential.

CNC Machine vs. Manual Methods

While manual methods can be useful in some situations, CNC machines offer several advantages that can make them a better choice for many projects. Some of the advantages of CNC machines over manual methods include:

1. Speed

CNC machines can work much faster than manual methods, which can help you complete projects more quickly and increase your earning potential.

2. Precision

CNC machines offer unparalleled precision that can help you create high-quality products with accuracy and consistency.

3. Reproducibility

CNC machines can reproduce the same design over and over again with the same level of precision, which can help you create consistent products and increase your earning potential.

4. Complexity

CNC machines can create complex designs that would be difficult or impossible to create with manual methods. This can help you expand your business and increase your earning potential.

Conclusion

In conclusion, the amount you can earn with a CNC machine will depend on several factors, including the type and quality of the machine, your skill level, and the type of projects you are working on. However, with the right approach and the right equipment, a CNC machine can be an excellent investment that can help you increase your earning potential and grow your business.

Frequently Asked Questions

In this section, we will answer some common questions related to the earning potential of a CNC machine.

What is the average income of a CNC machine operator?

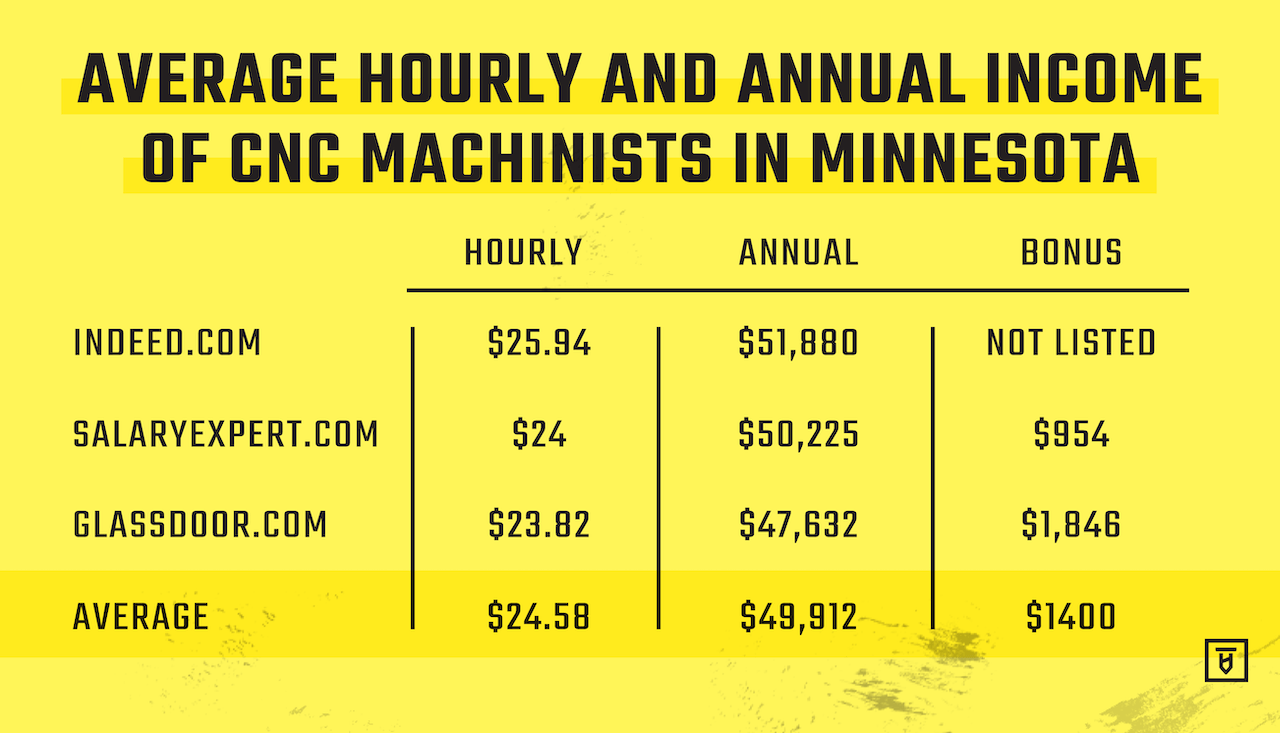

The income of a CNC machine operator varies based on several factors such as experience, location, industry, and employer. According to the Bureau of Labor Statistics, the median annual wage for a CNC machine operator in the United States is around $43,000. However, highly skilled and experienced operators can earn more than $60,000 per year. The earning potential also depends on the type of CNC machine, with operators of more complex machines generally earning more.

Additionally, CNC machine operators may have the opportunity to work overtime or receive bonuses, which can increase their income. Some operators also choose to work as freelancers and charge per project, which can lead to a higher income if they have a steady stream of clients.

Can you make money with a CNC machine at home?

Yes, it is possible to make money with a CNC machine at home. With the rise of e-commerce platforms and online marketplaces, it has become easier to sell custom-made products or services. If you have a CNC machine and the necessary skills, you can create unique items such as engraved signs, jewelry, or personalized gifts and sell them online or at local markets.

However, it is important to keep in mind that running a business from home requires dedication and hard work. You will need to market your products effectively, manage your finances, and ensure that you have a steady stream of customers. Additionally, you may need to comply with local laws and regulations related to running a home-based business.

What are the factors that affect the profitability of a CNC machine business?

Several factors can affect the profitability of a CNC machine business, including the cost of materials, labor, and overhead expenses such as rent and utilities. The type of CNC machine and its maintenance costs can also impact the profitability. In addition, the pricing strategy and competition in the market can affect the business’s ability to attract and retain customers.

Marketing and sales efforts can also play a role in determining the profitability of a CNC machine business. Effective marketing can help generate leads and increase sales, while poor marketing can lead to low visibility and a lack of customers. Finally, the skill and experience of the operator can impact the quality of the products, the efficiency of the production process, and the overall profitability of the business.

What are some examples of profitable CNC machine businesses?

There are several examples of profitable CNC machine businesses across various industries. One example is the custom furniture industry, where CNC machines are used to create unique and intricate designs. Other examples include the jewelry industry, where CNC machines are used to create custom pieces, and the automotive industry, where CNC machines are used for precision cutting and shaping of parts.

Another example is the prototyping industry, where CNC machines are used to create prototypes of new products quickly and accurately. This industry is especially popular in the tech sector, where companies need to test new designs and products before mass production. Finally, the home decor industry is another area where CNC machines can be profitable, with many businesses creating custom signs, wall art, and other home decor items.

What are some tips for starting a profitable CNC machine business?

Starting a profitable CNC machine business requires careful planning and execution. First, it is important to research the market and identify a niche that has demand and potential for growth. Next, you will need to invest in high-quality equipment and software to ensure that you can create high-quality products efficiently.

You will also need to develop a pricing strategy that is competitive but also allows you to make a profit. Additionally, it is important to market your business effectively, both online and offline. Finally, you should continuously improve your skills and knowledge to stay up-to-date with the latest technologies and trends in the industry.

In conclusion, the earning potential of CNC machines is vast and largely dependent on a variety of factors. The type of machine, the materials being used, the complexity of the design, and the level of skill of the operator can all impact the amount of money that can be made with a CNC machine.

However, with the right knowledge and experience, CNC machines can be a lucrative investment. Whether you are a hobbyist looking to turn your passion into profit, or a business owner seeking to expand your capabilities and increase revenue, a CNC machine can help you achieve your goals.

So, if you are considering investing in a CNC machine, it is important to do your research and choose the right machine for your needs. With the potential to earn a significant amount of money, a CNC machine can be a valuable asset for any individual or business in the manufacturing industry.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com