Table of Contents

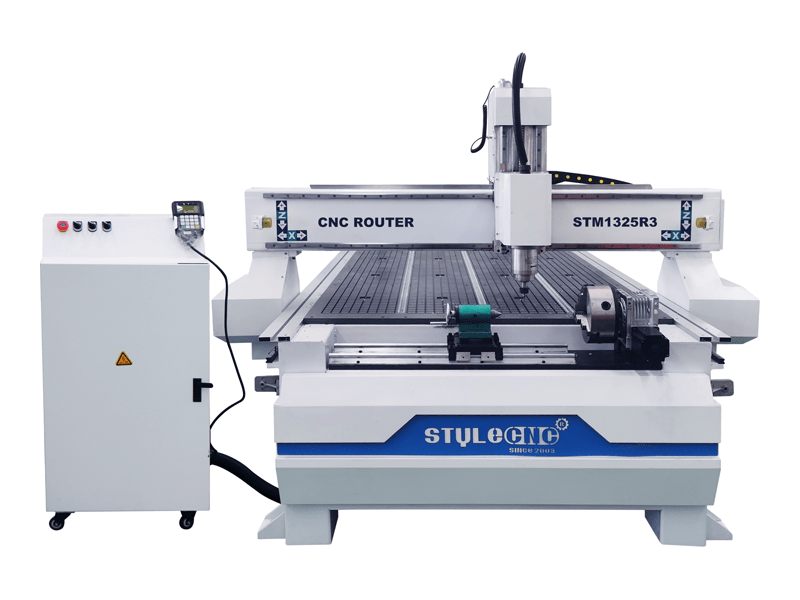

CNC routers have become a popular tool for woodworking, metalworking, and other manufacturing processes. However, the cost of a CNC router can vary greatly depending on the size, features, and quality of the machine. If you’re considering purchasing a CNC router, it’s important to understand the factors that affect its price and what you can expect to pay for a machine that meets your needs.

In this article, we’ll explore the various costs associated with CNC routers, from entry-level hobby machines to high-end industrial models. We’ll also discuss the features and capabilities that can impact the price of a CNC router, as well as some tips for finding the best deal on a machine that fits your budget. So, whether you’re a professional woodworker or a DIY enthusiast, read on to learn more about the cost of CNC routers and what you should expect to pay for one.

A CNC router cost varies depending on its size, power, and features. Entry-level models with a small cutting area can cost as little as $500, while larger, more powerful routers with advanced features can cost upwards of $50,000. The cost of a CNC router also includes software, tooling, and accessories, which can add to the overall expense. It’s important to research and compare different models to find the one that fits your needs and budget.

How Much Does a CNC Router Cost?

CNC routers are an essential tool for businesses and hobbyists alike who want to create precision cuts and designs in various materials. These machines have become more accessible in recent years, but the cost can still vary widely depending on the size, features, and materials they can work with. In this article, we’ll explore the factors that affect the cost of a CNC router and what you can expect to pay for one.

Size and Capacity

The size and capacity of a CNC router are the most significant factors affecting its price. Small machines designed for hobbyists and home use can cost as little as $500, while larger industrial models can cost upwards of $100,000. The size of the machine determines the maximum size of the material that can be worked on, as well as the number of axes the machine can move along. The more axes a machine has, the more complex and precise the cuts it can make.

When considering size and capacity, it’s essential to think about your long-term needs. If you expect to grow your business or work on larger projects in the future, investing in a larger machine may be more cost-effective in the long run.

Materials

CNC routers can work with a variety of materials, including wood, plastic, and metal. The type of material you plan to work with will affect the cost of the machine. Machines designed for woodworking are often less expensive than those designed for metalworking or other industrial applications. If you plan to work with multiple materials, you may need to invest in a more versatile machine, which can increase the cost.

Features and Accessories

CNC routers can come with a range of features and accessories to enhance their performance and versatility. Some common features include automatic tool changers, dust collection systems, and software for designing and programming cuts. These features can add to the cost of the machine, but they can also improve efficiency and precision, saving time and minimizing waste.

When considering features and accessories, it’s essential to think about your specific needs. Some features may be essential for your work, while others may be unnecessary or redundant.

Brand and Quality

The brand and quality of the machine can also affect its cost. Established brands with a reputation for quality and reliability may charge a premium for their products. However, investing in a high-quality machine can save you money in the long run by reducing maintenance and repair costs.

When considering brand and quality, it’s essential to do your research and read reviews from other users. You should also consider the level of support and service offered by the manufacturer, as this can affect your experience with the machine.

Installation and Training

The cost of a CNC router doesn’t just include the machine itself. You’ll also need to consider the cost of installation and training. Some manufacturers offer installation and training as part of the purchase price, while others charge extra for these services.

Proper installation and training are essential for getting the most out of your machine and ensuring its longevity. Investing in professional installation and training may be worth the extra cost in the long run.

Maintenance and Repairs

Like any machine, a CNC router requires regular maintenance and occasional repairs. The cost of maintenance and repairs can vary depending on the complexity of the machine and the severity of the issue. Some manufacturers offer warranties and service plans to cover these costs, while others charge extra for these services.

When considering maintenance and repairs, it’s essential to factor these costs into your budget and plan accordingly. Regular maintenance can help prevent more costly repairs in the future.

Benefits of a CNC Router

Despite the cost, investing in a CNC router can offer significant benefits for businesses and hobbyists alike. These machines offer precision and efficiency that is difficult to achieve with manual tools. CNC routers can also work with a variety of materials and designs, allowing for greater creativity and flexibility in your work.

In addition to the benefits of the machine itself, investing in a CNC router can also save time and money in the long run. These machines can produce complex designs and cuts quickly and accurately, reducing waste and minimizing the need for manual labor.

CNC Router vs. Manual Tools

When considering the cost of a CNC router, it’s essential to compare it to the cost of manual tools. While manual tools may be less expensive upfront, they require more time and labor to achieve similar results. CNC routers offer greater precision and efficiency, allowing you to produce more work in less time.

Investing in a CNC router can also help you expand your capabilities and take on more complex projects. Manual tools may be limited by their size, power, and versatility, while CNC routers can work with a variety of materials and designs.

Conclusion

The cost of a CNC router can vary widely depending on the size, materials, features, and brand. While these machines may be expensive upfront, they offer significant benefits in precision, efficiency, and versatility. When considering the cost of a CNC router, it’s essential to think about your long-term needs and factor in the costs of installation, training, maintenance, and repairs. By investing in a high-quality CNC router, you can expand your capabilities and take your work to the next level.

Frequently Asked Questions

Here are some common questions and answers about the cost of CNC routers.

What factors affect the price of a CNC router?

The cost of a CNC router can vary widely depending on several factors. The size and power of the machine, the type of materials it can handle, and the complexity of the software required to operate it can all impact the cost. Additionally, some brands and models may be more expensive due to their reputation for quality or additional features.

It is important to consider your specific needs and budget when selecting a CNC router, as investing in a high-end machine with features you may not use can be a waste of money.

What is the average cost of a CNC router?

The average cost of a CNC router ranges from $4,000 to $40,000, depending on the size and capabilities of the machine. Smaller, hobbyist-level routers may be less expensive, while larger industrial-grade machines can cost significantly more. Additionally, the cost of operating and maintaining the machine should also be taken into account when determining the overall cost.

When considering the cost of a CNC router, it is important to also factor in any necessary accessories or software, as these can add to the overall expense.

Is it worth investing in a high-end CNC router?

Investing in a high-end CNC router can be worthwhile for businesses or individuals who require precision and speed in their work. These machines often have more advanced features and can handle a wider range of materials, allowing for greater flexibility in design and production. Additionally, high-end machines may require less maintenance and have longer lifespans, making them a more cost-effective investment in the long run.

However, for those who only require basic functionality or have a limited budget, a lower-end CNC router may be a more practical choice.

What are some popular brands of CNC routers?

There are many reputable brands of CNC routers available on the market, including ShopBot, Axiom Precision, and Laguna Tools. These brands offer a range of machines at different price points and with varying capabilities to suit different needs. Other popular brands include Haas, Multicam, and Thermwood.

When selecting a brand of CNC router, it is important to research the reputation of the company and read reviews from other users to ensure that the machine meets your needs and expectations.

Can I purchase a used CNC router to save money?

Purchasing a used CNC router can be a cost-effective way to acquire a machine, but it is important to carefully inspect the machine and its components before making a purchase. Used machines may have worn or damaged parts that could lead to costly repairs, and may not offer the same level of precision or performance as a new machine.

If you do decide to purchase a used CNC router, it is important to work with a reputable seller and ask for detailed information about the machine’s history and maintenance. Additionally, you may want to consider purchasing a warranty or service agreement to protect your investment.

In conclusion, the cost of a CNC router can vary greatly depending on the size, capabilities, and features you are looking for. However, investing in a CNC router can ultimately save you time and money in the long run by increasing efficiency and productivity in your production process. It is important to do research and carefully consider your needs before making a purchase.

Overall, the cost of a CNC router can range from a few thousand dollars for a basic, small-scale machine to hundreds of thousands of dollars for a large, high-end model. It is important to factor in additional costs such as software, maintenance, and training when budgeting for a CNC router. Additionally, considering used or refurbished models can provide a cost-effective option without sacrificing quality.

Ultimately, the cost of a CNC router should be viewed as an investment in your business. By increasing precision, speed, and flexibility in your production process, a CNC router can help your business grow and succeed in today’s competitive market. With careful consideration and planning, you can find a CNC router that fits your budget and meets your production needs.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com