Table of Contents

If you’re looking to invest in a CNC water jet, one of the first questions you’ll likely have is “How much does it cost?” The answer, unfortunately, isn’t a simple one. The price of a CNC water jet can vary widely depending on a range of factors, from the size and power of the machine to the brand and features included. In this article, we’ll break down some of the key cost considerations to help you get a better sense of what you can expect to pay for a CNC water jet.

The cost of a CNC water jet varies depending on the size, features, and quality of the machine. Entry-level machines with basic features can start at around $40,000, while high-end machines with advanced features and larger cutting areas can cost upwards of $500,000. It’s important to do your research and consider your specific needs before investing in a CNC water jet.

How Much Does a CNC Water Jet Cost?

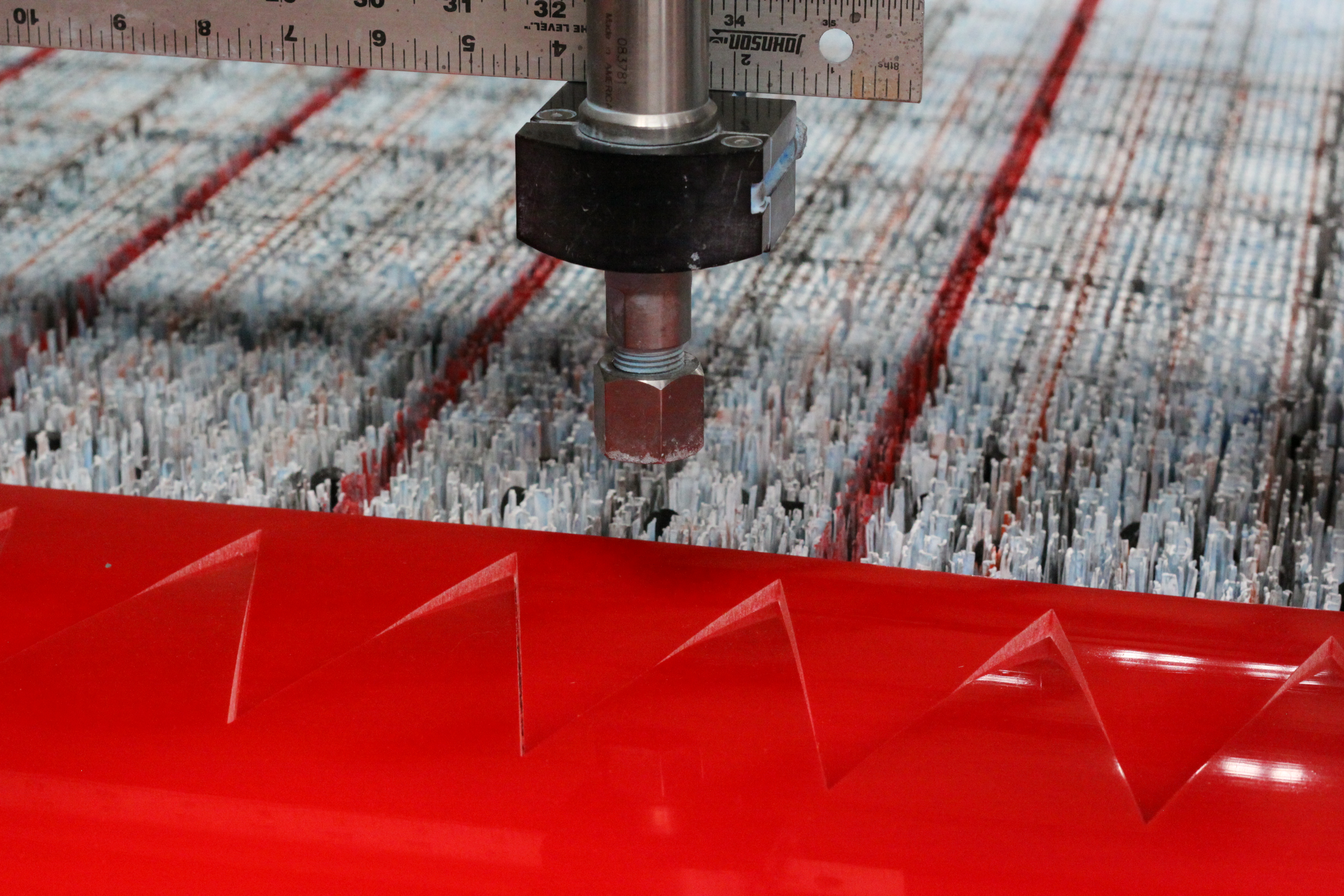

CNC water jet cutting is a process that involves using a high-pressure stream of water mixed with an abrasive material to cut through various materials. CNC water jet machines are incredibly versatile and can cut through a wide range of materials with high precision. However, one of the main concerns for those interested in purchasing a CNC water jet machine is the cost. In this article, we will explore the factors that affect the cost of a CNC water jet machine, and what you can expect to pay for one.

Factors Affecting the Cost of a CNC Water Jet Machine

There are several factors that can affect the cost of a CNC water jet machine, including:

1. Size of the Machine

The size of the CNC water jet machine is one of the most significant factors that impact its cost. Larger machines that can cut through thicker materials tend to be more expensive than smaller ones.

2. Type of Cutting Head

The type of cutting head that the CNC water jet machine uses can also affect its cost. Machines with more advanced cutting heads that can handle more complex cuts tend to be more expensive.

3. Pump Power

The power of the pump that drives the water through the cutting head can also impact the cost of the machine. Machines with more powerful pumps tend to be more expensive.

4. Software and Control System

The software and control system used by the machine can also affect its cost. Machines with more advanced software and control systems tend to be more expensive.

What to Expect to Pay for a CNC Water Jet Machine

The cost of a CNC water jet machine can vary widely depending on the factors listed above. However, as a general rule, you can expect to pay anywhere from $50,000 to $500,000 for a CNC water jet machine.

Benefits of CNC Water Jet Cutting

CNC water jet cutting offers several benefits, including:

- High precision cutting

- Versatility to cut through a wide range of materials

- Ability to cut complex shapes and patterns

- Minimal material waste

- No heat-affected zone, which can reduce the risk of material distortion

CNC Water Jet vs. Other Cutting Methods

CNC water jet cutting offers several advantages over other cutting methods, including:

| Cutting Method | Advantages | Disadvantages |

|---|---|---|

| Laser Cutting | High precision cutting, ability to cut through thin materials | Cannot cut through thick or reflective materials, heat-affected zone can cause material distortion |

| Plasma Cutting | Fast cutting speed, ability to cut through thick materials | Less precise than other cutting methods, heat-affected zone can cause material distortion |

| Wire EDM | High precision cutting, ability to cut through hard materials | Less versatile than other cutting methods, slower cutting speed |

In conclusion, CNC water jet cutting is an efficient and versatile cutting method that offers high precision and the ability to cut through a wide range of materials. While the cost of a CNC water jet machine can vary widely depending on several factors, you can expect to pay anywhere from $50,000 to $500,000 for one. If you are looking for a cutting method that offers minimal material waste, no heat-affected zone, and the ability to cut complex shapes and patterns, CNC water jet cutting may be the right choice for your needs.

Frequently Asked Questions

Find answers to commonly asked questions about the cost of CNC water jet.

What is a CNC Water Jet?

A CNC water jet is a machine that uses a high-pressure stream of water to cut through materials such as metal, stone, and glass. The machine is controlled by a computer numerical control (CNC) system, which allows for precise and intricate cuts. This type of machine is often used in industrial settings, but can also be used for smaller-scale projects.

The cost of a CNC water jet can vary greatly depending on factors such as the size of the machine, the materials it can cut, and the software it uses. Generally, a basic machine may cost around $50,000, while a larger, more advanced machine can cost upwards of $500,000.

What are the Benefits of a CNC Water Jet?

One of the main benefits of a CNC water jet is its ability to cut through a wide range of materials with precision and speed. This makes it an ideal choice for industries such as aerospace, automotive, and architecture, where complex cuts are often required. Additionally, the water jet cutting process does not produce heat, which means there is no risk of warping or damaging the material being cut.

While the initial cost of a CNC water jet may be high, the machine can provide significant cost savings in the long run by reducing material waste and increasing efficiency. It can also help businesses stay competitive by offering faster turn-around times and more complex cutting capabilities.

What Factors Affect the Cost of a CNC Water Jet?

Several factors can influence the cost of a CNC water jet, including the size of the machine, the materials it can cut, and the software it uses. Larger machines with more advanced cutting capabilities will generally cost more than smaller, basic machines. Additionally, machines that can cut through thicker or harder materials will also be more expensive.

The software used to control the machine can also affect the cost, as more advanced software may be required for more complex cutting jobs. Other factors to consider include the cost of maintenance and repairs, as well as any additional accessories or features that may be needed.

What is the Cost of Operating a CNC Water Jet?

The cost of operating a CNC water jet can vary depending on several factors, including the cost of electricity, water, and abrasive materials. Additionally, the cost of maintenance and repairs should also be factored into the overall cost of operation. It is important to regularly maintain the machine to ensure it is running efficiently and to prevent costly breakdowns.

Despite these costs, a CNC water jet can provide significant cost savings in the long run by reducing material waste and increasing efficiency. The machine can also help businesses stay competitive by offering faster turn-around times and more complex cutting capabilities.

What are the Maintenance Requirements for a CNC Water Jet?

Maintenance requirements for a CNC water jet may vary depending on the specific machine and how frequently it is used. Generally, the machine should be regularly cleaned and inspected for any signs of wear or damage. The water and abrasive tanks should also be emptied and refilled on a regular basis.

In addition, the machine should be serviced by a qualified technician on a regular basis to ensure it is running efficiently and to prevent costly breakdowns. It is important to follow the manufacturer’s recommended maintenance schedule to ensure the machine operates at its full potential.

In conclusion, the cost of a CNC water jet machine can vary greatly depending on several factors, such as the size of the machine, the complexity of the design, and the materials used. However, it is important to note that investing in a high-quality CNC water jet machine can significantly increase productivity and efficiency in your business.

When considering the cost of a CNC water jet machine, it is also important to consider the long-term benefits it can provide. With its ability to cut through a wide range of materials with precision and speed, a CNC water jet machine can help businesses save time and money in the long run.

Ultimately, the cost of a CNC water jet machine should be viewed as an investment in the future of your business. By choosing the right machine for your needs and budget, you can enjoy the benefits of increased productivity, efficiency, and profitability for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com