Table of Contents

CNC machining has revolutionized the manufacturing industry, making it possible to produce high-quality parts with extreme precision. However, one question that often arises when it comes to CNC machining is how much it costs to machine a part. The answer to this question is not straightforward, as there are many factors that can affect the cost of CNC machining. In this article, we will explore some of these factors and provide you with a better understanding of the cost of CNC machining. So, let’s dive in!

The cost to CNC machine a part depends on various factors such as the complexity of the part, material, quantity, and tolerances required. Generally, the cost can range from $50 to $250 per hour of machining time. It is recommended to request a quote from a reputable CNC machining service provider to get an accurate estimate for your specific part.

How Much Does It Cost to CNC Machine a Part?

CNC machining has become an essential part of the manufacturing industry, and it is a process that involves using computer-controlled machines to produce high-precision parts. However, the cost of CNC machining can vary depending on several factors, including the complexity of the part, the tolerances required, the material used, and the quantity of parts needed. Here’s a breakdown of the factors that affect the cost of CNC machining:

1. Part Complexity

The complexity of the part is one of the main factors that affect the cost of CNC machining. The more complex the part, the more time and effort it takes to machine it. Parts with intricate designs, tight tolerances, and multiple features will require more machining time and tool changes, which can drive up the cost.

To reduce the cost of machining complex parts, manufacturers can use techniques such as design for manufacturing (DFM) and design for assembly (DFA). These techniques optimize the design of the part for manufacturability and assembly, making it easier and more cost-effective to produce.

2. Material Used

The material used for the part also affects the cost of CNC machining. Some materials are more expensive than others, and some require specialized tooling and machining techniques. For example, machining aluminum is generally less expensive than machining steel or titanium.

To reduce the cost of machining parts, manufacturers can consider using alternative materials that offer similar properties to the original material but at a lower cost. For example, using a plastic material instead of metal can significantly reduce the cost of machining.

3. Tolerances Required

The tolerances required for the part also affect the cost of CNC machining. Tighter tolerances require more precise machining, which can be more time-consuming and require specialized tooling. Parts that require high accuracy and precision will have a higher cost than those that have looser tolerances.

To reduce the cost of machining parts with tight tolerances, manufacturers can consider using statistical process control (SPC) techniques. These techniques monitor the machining process and adjust it as needed to ensure that the parts meet the required tolerances.

4. Quantity of Parts Needed

The quantity of parts needed is another factor that affects the cost of CNC machining. Machining a single part is generally more expensive than machining several identical parts. This is because the setup time and tooling costs are spread out over a larger quantity of parts, reducing the cost per part.

To reduce the cost of machining a small quantity of parts, manufacturers can consider using rapid prototyping techniques such as 3D printing or CNC milling. These techniques allow for the quick and cost-effective production of small quantities of parts.

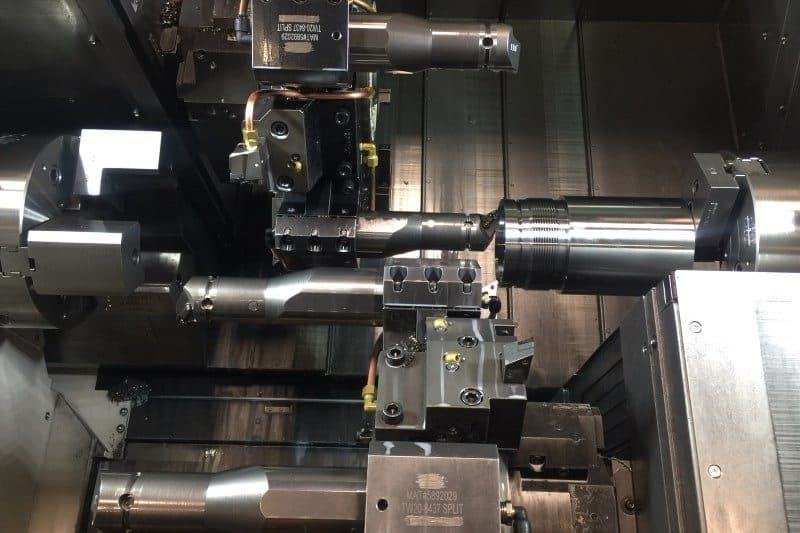

5. Machine Complexity

The complexity of the CNC machine used to produce the part also affects the cost of machining. Machines with more advanced features and capabilities are generally more expensive to operate and maintain, which can drive up the cost of machining.

To reduce the cost of machining, manufacturers can consider using simpler machines or outsourcing the machining to a third-party provider that has the necessary equipment.

6. Labor Costs

The labor costs associated with CNC machining can also affect the overall cost. Skilled machinists are required to operate the machines and produce high-quality parts. The cost of labor can vary depending on the location and experience of the machinist.

To reduce the cost of labor, manufacturers can consider outsourcing the machining to a third-party provider that has access to skilled labor at a lower cost.

7. Post-Machining Processes

Post-machining processes such as surface finishing, coating, and assembly can also affect the cost of CNC machining. These processes require additional time and resources, which can drive up the cost of the part.

To reduce the cost of post-machining processes, manufacturers can consider using alternative finishing techniques such as anodizing or powder coating, which are more cost-effective than traditional methods.

8. Quality Control

Quality control is an essential part of CNC machining, and it can also affect the cost of the part. Ensuring that the part meets the required specifications and tolerances requires additional time and resources, which can drive up the cost.

To reduce the cost of quality control, manufacturers can use automated inspection techniques such as coordinate measuring machines (CMMs) or optical inspection systems. These techniques are more efficient and accurate than manual inspection processes.

9. Benefits of CNC Machining

Despite the cost of CNC machining, there are many benefits to using this process. CNC machining allows for the production of high-precision parts with consistent quality and accuracy. It also allows for the rapid prototyping and production of parts, reducing lead times and increasing efficiency.

Using CNC machining also allows for greater design flexibility, as the machines can produce parts with complex geometries and features that would be difficult or impossible to produce using traditional manufacturing methods.

10. CNC Machining vs. Traditional Manufacturing

Compared to traditional manufacturing methods such as casting, forging, and stamping, CNC machining offers several advantages. CNC machining allows for greater design flexibility, higher precision, and the production of smaller quantities of parts at a lower cost.

Traditional manufacturing methods require specialized tooling and equipment, which can be expensive to set up and maintain. They also have limitations in terms of the complexity of the parts they can produce and the tolerances they can achieve.

In conclusion, the cost of CNC machining depends on several factors, including the complexity of the part, the material used, the tolerances required, the quantity of parts needed, the machine complexity, labor costs, post-machining processes, and quality control. By optimizing these factors, manufacturers can reduce the cost of CNC machining and enjoy the many benefits it offers.

Frequently Asked Questions

Here are some common questions and answers about the cost of CNC machining a part.

What factors affect the cost of CNC machining a part?

The cost of CNC machining a part can vary depending on several factors. One of the main factors is the complexity of the part. Parts that have intricate designs and require multiple setups will cost more to machine. The material used to make the part also affects the cost. Some materials are more expensive than others and require special tools to machine. The quantity of parts being produced can also impact the cost. The more parts being produced, the lower the per-part cost typically is.

Other factors that can affect the cost of CNC machining a part include the type of machine being used, the experience and skill of the machinist, and the location of the machining facility.

What is the average cost of CNC machining a part?

The average cost of CNC machining a part can vary widely depending on the factors mentioned above. However, as a general rule, the cost can range from $50 to $500 for a simple part and up to several thousand dollars for a more complex part. It’s important to get a quote from a machining company to accurately determine the cost of machining your specific part.

Keep in mind that the cost of machining a part is just one aspect of the overall cost. There may be additional costs for materials, finishing, and shipping, depending on your specific needs.

Can the cost of CNC machining a part be reduced?

Yes, there are several ways to potentially reduce the cost of CNC machining a part. One way is to simplify the design of the part. The more complex the design, the more time and effort it will take to machine, which drives up the cost. Another way to reduce cost is to choose a less expensive material. However, it’s important to consider the strength and durability of the material when making this decision. Finally, producing a larger quantity of parts can often result in a lower per-part cost.

Working with an experienced machining company can also help reduce costs. They may be able to suggest design changes or offer suggestions for more cost-effective materials or processes.

How long does it take to CNC machine a part?

The time it takes to CNC machine a part can vary depending on the complexity of the part and the equipment being used. Simple parts may only take a few minutes to machine, while more complex parts may take several hours or even days. The machining process typically involves several stages, including programming, setup, and actual machining, each of which can add to the overall time required.

It’s important to work with a machining company that can provide an accurate estimate of the time required to machine your specific part, as this can impact delivery times and overall project timelines.

How do I choose a CNC machining company?

Choosing a CNC machining company requires careful consideration of several factors. One of the most important factors is experience. Look for a company with a proven track record of producing high-quality parts and delivering on time. It’s also important to consider the equipment and technology the company uses, as well as their ability to work with a variety of materials.

Other factors to consider include pricing, customer service, and location. Make sure the company can provide a detailed quote based on your specific needs, and that they are responsive and easy to work with. Finally, consider the company’s reputation and reviews from other customers before making a final decision.

In conclusion, the cost of CNC machining a part can vary greatly depending on a number of factors, including the complexity of the part, the material it is made from, and the quantity being produced. However, by working with a reputable and experienced CNC machining provider, you can ensure that you are getting the best possible value for your investment.

While cost is certainly an important consideration when it comes to CNC machining, it is also important to bear in mind the many benefits that this technology offers. From improved accuracy and precision to faster turnaround times and increased efficiency, CNC machining can help you to achieve your goals and take your business to the next level.

So if you are looking for a reliable and cost-effective way to produce high-quality parts, CNC machining may be just what you need. With the right provider and a little bit of research, you can enjoy all the benefits of this powerful technology without breaking the bank.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com