Injection molding is a widely adopted manufacturing technique that is used to produce a large number of plastic products in the industry. However, before you can start the production process, you need to know how much it costs to make an injection mold. This is a crucial step in the process, as the cost of the mold can significantly impact your overall production expenses.

The cost of making an injection mold varies depending on several factors, such as the size of the mold, the complexity of the design, and the materials used. In this article, we will delve into these factors and provide you with an overview of the costs associated with making an injection mold. Whether you are a manufacturer or a consumer, understanding the cost of injection molding can help you make more informed decisions about your products.

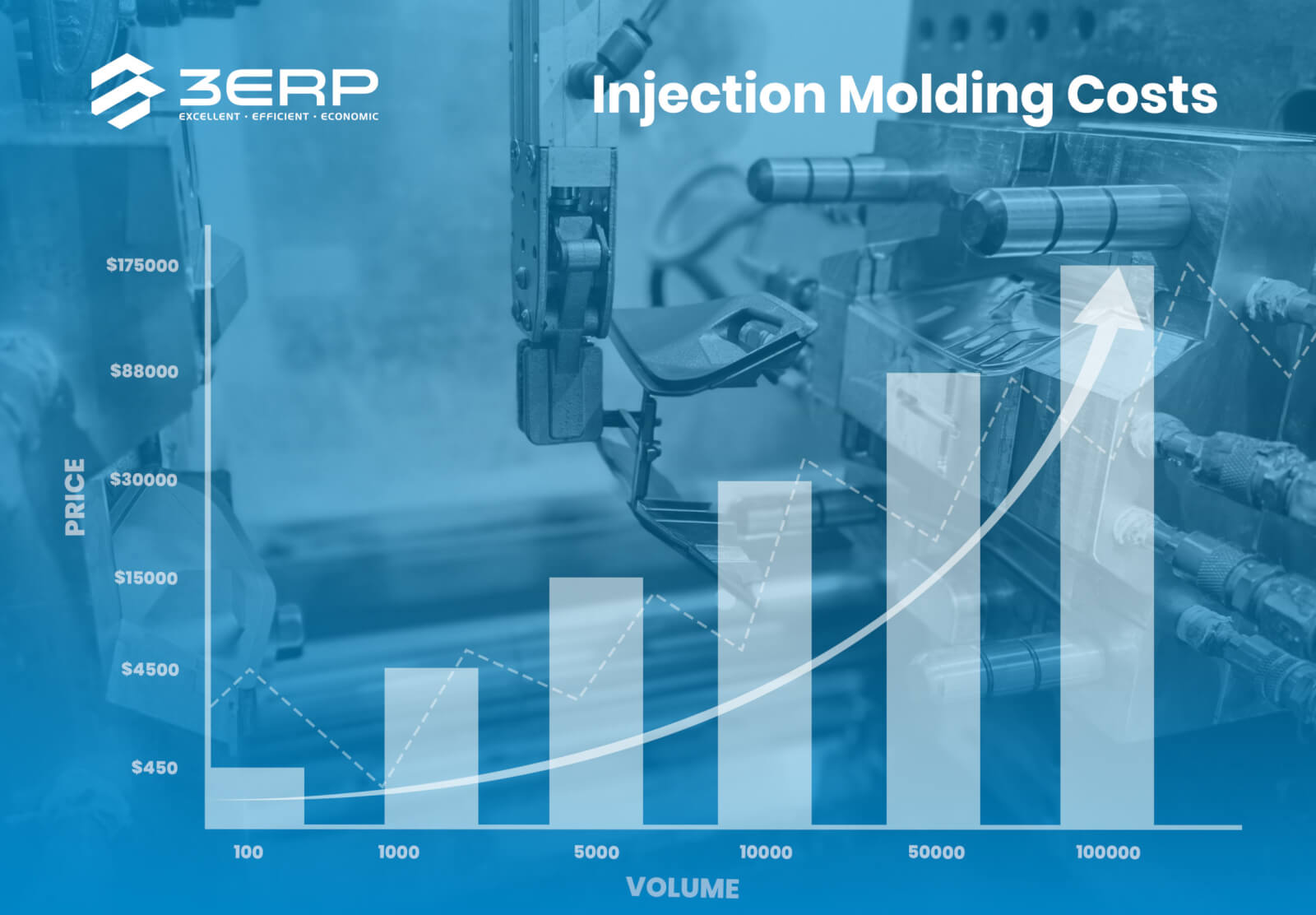

The cost of making an injection mold can vary greatly depending on factors such as the size and complexity of the mold, the material used, and the quantity of parts needed. On average, a simple injection mold can cost anywhere from $1,000 to $5,000. However, for more complex molds, the cost can range from $10,000 to $100,000 or more. It’s important to get a quote from a reputable mold maker to get an accurate idea of the cost.

How Much Does It Cost to Make an Injection Mold?

Injection molding is a widely used manufacturing process that produces high-quality and precise plastic parts. However, the cost of making an injection mold can vary depending on several factors. In this article, we will explore the different factors that affect the cost of making an injection mold.

Types of Injection Molds

There are two types of injection molds: prototype and production molds. A prototype mold is a low-volume production mold used to produce a small number of parts. A production mold, on the other hand, is a high-volume production mold used to produce millions of parts. The cost of making a prototype mold is lower than that of making a production mold.

The cost of a prototype mold can range from $1,000 to $5,000, depending on its complexity and size. A production mold, on the other hand, can cost between $10,000 and $100,000, depending on the number of cavities, the complexity of the mold, and the size of the parts.

Factors Affecting the Cost of Injection Molds

1. Size and Complexity of the Part:

The size and complexity of the part to be produced play a significant role in the cost of making an injection mold. The larger and more complex the part, the more expensive the mold will be.

2. Number of Cavities:

The number of cavities in the mold also affects the cost of making an injection mold. The more cavities the mold has, the higher the cost of the mold.

3. Type of Material:

The type of material used in the injection molding process also affects the cost of making an injection mold. Different materials have different melting points, and the molds need to be designed accordingly.

4. Tolerance Requirements:

The tolerance requirements of the part also affect the cost of making the injection mold. The tighter the tolerance requirements, the more precise the mold needs to be, which increases the cost.

Benefits of Injection Molding

1. High Efficiency:

Injection molding is a highly efficient manufacturing process that can produce high volumes of parts in a short amount of time.

2. High Precision:

Injection molding can produce highly precise parts with tight tolerances.

3. Versatility:

Injection molding can be used to produce a wide range of parts, from small components to large parts.

Injection Molding vs. Other Manufacturing Processes

1. Injection Molding vs. 3D Printing:

Injection molding is a more cost-effective option for high-volume production runs. 3D printing is more suitable for low-volume production runs.

2. Injection Molding vs. CNC Machining:

Injection molding is a more efficient and cost-effective option for producing large volumes of parts. CNC machining is more suitable for producing small volumes of parts.

Conclusion

The cost of making an injection mold can vary depending on several factors, including the size and complexity of the part, the number of cavities, the type of material used, and the tolerance requirements. However, injection molding is a highly efficient and cost-effective manufacturing process that can produce high-quality and precise parts. By understanding the factors that affect the cost of making an injection mold, manufacturers can make informed decisions about the best production strategy for their needs.

Frequently Asked Questions

Injection molding is a common manufacturing process that is used to produce a wide range of plastic products. One of the key considerations of the injection molding process is the cost of the injection mold. Here are some frequently asked questions about the cost of injection molds:

What factors affect the cost of an injection mold?

The cost of an injection mold can vary widely depending on a number of factors. Some of the factors that can affect the cost of an injection mold include the complexity of the part, the size of the part, the materials used to make the mold, and the number of cavities in the mold. Other factors that can affect the cost include the lead time required to manufacture the mold and the location of the manufacturer.

Ultimately, the cost of an injection mold will depend on the specific requirements of the project. It is important to work with an experienced injection molding company that can help you understand the factors that will impact the cost of your project and provide you with an accurate estimate.

What is the typical cost range for an injection mold?

The cost of an injection mold can vary widely depending on the factors mentioned above. However, as a general rule, small, simple molds can cost anywhere from $1,000 to $5,000. Larger, more complex molds can cost upwards of $100,000 or more.

It is important to keep in mind that the cost of the mold is just one factor to consider when evaluating the overall cost of an injection molding project. Other factors, such as material costs, labor costs, and shipping costs, should also be taken into account.

Is it possible to reduce the cost of an injection mold?

There are a number of strategies that can be used to reduce the cost of an injection mold. One of the most effective strategies is to simplify the part design. By reducing the complexity of the part, it may be possible to use a smaller, less expensive mold.

Another strategy for reducing the cost of an injection mold is to work with an experienced injection molding company that can help you identify opportunities to reduce costs. For example, they may be able to suggest alternative materials or production methods that can help you achieve the desired results at a lower cost.

How long does it take to manufacture an injection mold?

The lead time required to manufacture an injection mold can vary widely depending on a number of factors, including the complexity of the mold, the size of the mold, and the materials used to make the mold. In general, however, it can take anywhere from a few weeks to several months to manufacture an injection mold.

It is important to factor in the lead time when planning an injection molding project. Working with an experienced injection molding company that has a proven track record of delivering high-quality molds on time can help ensure that your project stays on schedule.

What should I look for in an injection molding company?

When choosing an injection molding company, there are a number of factors to consider. One of the most important factors is experience. You want to work with a company that has a proven track record of delivering high-quality molds and parts.

Other factors to consider include the company’s capabilities, lead times, pricing, and customer service. It is also important to choose a company that is willing to work with you to understand your specific requirements and provide customized solutions that meet your needs.

In conclusion, determining the cost of an injection mold can be a complex process that involves various factors such as the size and complexity of the mold, the material used, and the production volume. However, by understanding these factors and working with a reputable manufacturer, you can ensure that you get a high-quality mold that meets your needs and budget.

Moreover, it’s important to keep in mind that the cost of the mold is just one part of the equation. You also need to consider other expenses such as shipping, taxes, and maintenance costs. By factoring in these expenses, you can get a more accurate picture of the total cost of the mold.

Finally, investing in a high-quality injection mold can pay off in the long run by increasing the efficiency and quality of your production process. So, while the cost of the mold may seem daunting at first, it’s important to consider the potential benefits and weigh them against the initial expense.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com