Table of Contents

- Frequently Asked Questions

- What is the smallest dimension that can be achieved through aluminum extrusion?

- What factors affect the smallest dimension that can be extruded?

- Is there a limit to how small aluminum components can be made through extrusion?

- What are some common applications for small extruded aluminum components?

- What are some tips for designing small extruded aluminum components?

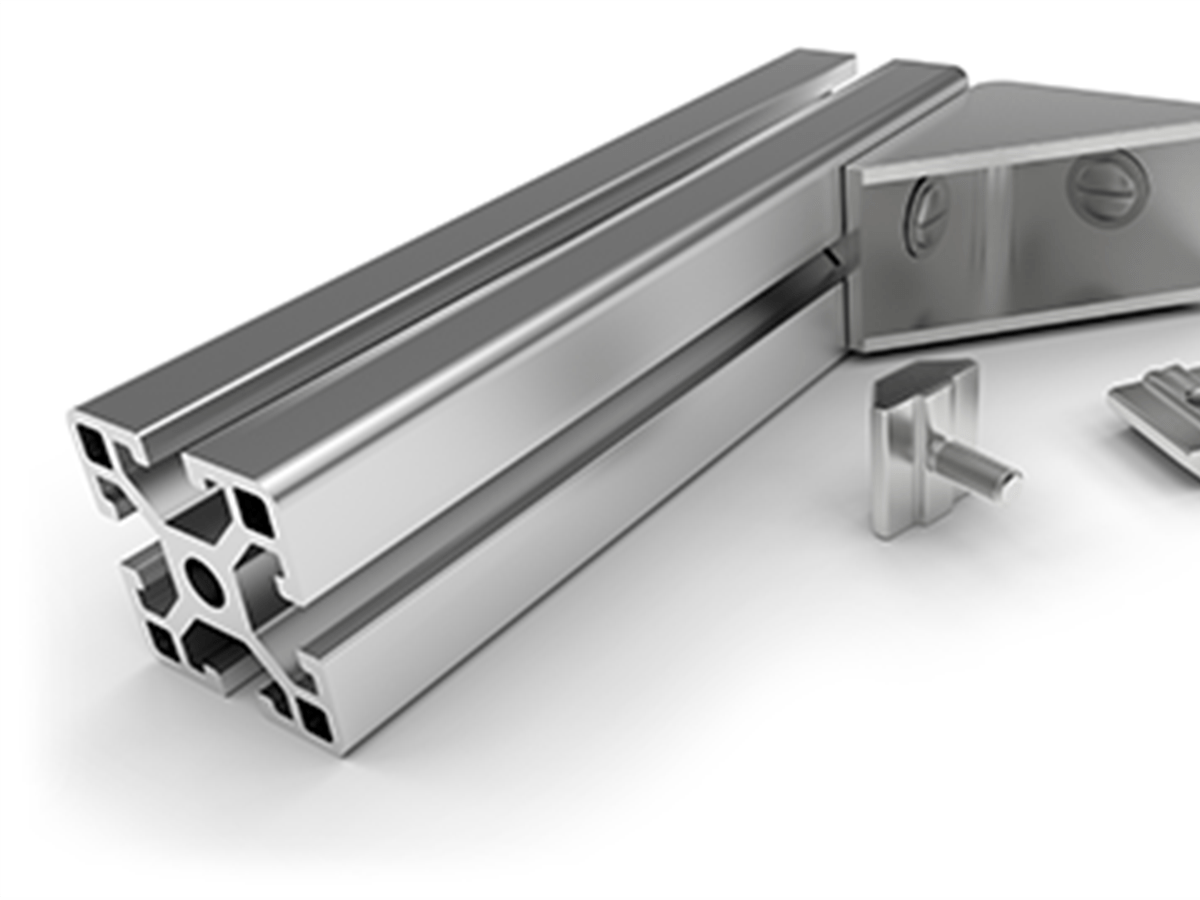

When it comes to aluminum extrusions, size matters. The question of how small extruded aluminum can be is a common one among manufacturers and designers alike. The answer depends on several factors, including the alloy type, the extrusion process, and the intended application. In this article, we’ll explore the world of extruded aluminum and shed some light on just how small it can go.

Aluminum extrusions are used in a wide range of industries, from architecture and construction to automotive and aerospace. They offer a versatile and cost-effective solution for creating complex shapes and designs with excellent strength-to-weight ratios. But as demand for smaller and more intricate components grows, so too does the need for extrusions that can meet these requirements. So, let’s dive in and see just how small extruded aluminum can be.

How Small Can Extruded Aluminum Be?

Extruded aluminum is a highly versatile and popular material used in a wide range of industries. One of the most common questions asked about this material is how small it can be extruded. In this article, we will explore the answer to this question, as well as the benefits and drawbacks of extruding small aluminum profiles.

1. The Basics of Extruding Aluminum

Extrusion is a manufacturing process that involves forcing a material through a die to create a specific shape. The process is widely used in the manufacturing of aluminum profiles for a variety of applications, including construction, automotive, electronics, and aerospace.

To extrude aluminum, the material is heated to its melting point and then forced through a die using a hydraulic press. The die is a specially designed tool that shapes the aluminum into the desired profile. Extruded aluminum profiles can be made in various shapes and sizes, from simple bars and tubes to complex geometric shapes.

2. The Minimum Size of Extruded Aluminum Profiles

The minimum size of an extruded aluminum profile depends on several factors, such as the complexity of the shape, the alloy used, and the extrusion process. In general, the smallest profiles that can be extruded are around 1mm in diameter or thickness.

However, the size of the profile can vary depending on the complexity of the shape. For example, simple shapes such as bars and tubes can be extruded to smaller sizes than more complex shapes such as hollow profiles or intricate geometries.

3. Benefits of Extruding Small Aluminum Profiles

There are several benefits of extruding small aluminum profiles. One of the main advantages is that smaller profiles can be used for applications where space is limited. For example, in the electronics industry, small aluminum profiles are used to create heat sinks and other components that need to be compact and lightweight.

Another benefit of extruding small aluminum profiles is that they can be produced with higher precision and accuracy than larger profiles. This is because the smaller size allows for more control over the extrusion process, resulting in a more consistent and uniform product.

4. Drawbacks of Extruding Small Aluminum Profiles

While there are many benefits to extruding small aluminum profiles, there are also some drawbacks to consider. One of the main challenges with extruding small profiles is that they can be more difficult to handle and process than larger profiles. This is because the smaller size makes them more fragile and prone to bending or warping during handling or finishing.

Another drawback of extruding small aluminum profiles is that they can be more expensive to produce than larger profiles. This is because the smaller size requires more precise and controlled manufacturing processes, which can increase production costs.

5. Extruding Small Aluminum Profiles vs. Other Materials

When it comes to creating small components or structures, extruded aluminum is not the only material choice available. Other materials, such as plastic and steel, can also be extruded to create small profiles.

However, there are several advantages to using aluminum over other materials. One of the main benefits is that aluminum is lightweight and has excellent strength-to-weight ratio, making it ideal for applications where weight is a concern. Aluminum is also highly resistant to corrosion and can withstand extreme temperatures.

6. Applications of Small Extruded Aluminum Profiles

Small extruded aluminum profiles are used in a wide range of applications across various industries. Some of the most common applications include:

– Electronics: Small aluminum profiles are used to create heat sinks, LED lighting fixtures, and other components.

– Automotive: Small aluminum profiles are used in the manufacturing of engine components, transmission parts, and other vehicle systems.

– Construction: Small aluminum profiles are used in the construction of doors, windows, and other building components.

– Aerospace: Small aluminum profiles are used in the manufacturing of aircraft components, such as wing struts and landing gear.

7. Choosing the Right Extrusion Partner

When it comes to extruding small aluminum profiles, it’s essential to choose the right extrusion partner. Look for a company with a proven track record of producing high-quality profiles and a strong commitment to customer service.

A reliable extrusion partner should also have the technical expertise to help you design and optimize your extruded aluminum profiles for your specific application. Look for a company that offers value-added services, such as finishing, machining, and assembly, to streamline your production process.

8. Conclusion

In conclusion, the minimum size of extruded aluminum profiles depends on several factors, including the complexity of the shape and the alloy used. While small aluminum profiles have many benefits, such as increased precision and accuracy, they can also be more challenging and expensive to produce than larger profiles.

When considering extruding small aluminum profiles, it’s essential to choose the right extrusion partner that can provide the technical expertise and value-added services you need to optimize your production process. With the right partner, you can take advantage of the many benefits of extruded aluminum and create high-quality products that meet your specific needs.

Frequently Asked Questions

Aluminum extrusion is a popular manufacturing process that involves shaping aluminum into specific designs and sizes. One common question is how small can extruded aluminum be? Here are 5 questions and answers that will help you understand this topic better.

What is the smallest dimension that can be achieved through aluminum extrusion?

The smallest dimension that can be achieved through aluminum extrusion is typically around 0.020 inches or 0.5 millimeters. However, this can vary depending on the complexity of the design and the specific capabilities of the extrusion equipment being used. In general, smaller dimensions require more precise equipment and tighter tolerances.

It’s also worth noting that extrusion is not the only process used to create small aluminum components. Other methods like stamping, forging, and casting may be more appropriate depending on the specific application and desired outcome.

What factors affect the smallest dimension that can be extruded?

Several factors can affect the smallest dimension that can be extruded from aluminum. One of the most important is the size and shape of the extrusion die. Dies with smaller openings and more intricate shapes are generally capable of producing smaller components.

Other factors include the quality of the aluminum used, the temperature and pressure of the extrusion process, and the skill and experience of the operator. By controlling these variables, manufacturers can achieve greater precision and consistency in their extruded products.

Is there a limit to how small aluminum components can be made through extrusion?

While there is no hard limit to how small aluminum components can be made through extrusion, there are practical considerations that come into play. For example, extremely small components may be difficult or impossible to handle during the extrusion process, or may be too fragile to survive the stresses of the process.

Additionally, smaller components may require higher levels of precision and tighter tolerances, which can increase the cost and complexity of the extrusion process. As a result, manufacturers must balance the benefits of smaller components against the practical challenges of producing them through extrusion.

What are some common applications for small extruded aluminum components?

Small extruded aluminum components are used in a wide range of applications across many industries. Some common examples include electrical connectors, heat sinks, and medical devices. These components are often prized for their high strength-to-weight ratio, corrosion resistance, and ability to be customized to fit specific needs.

Other applications for small extruded aluminum components include consumer electronics, automotive parts, and aerospace components. By using extrusion to create these components, manufacturers can achieve greater precision and consistency than would be possible through other manufacturing methods.

What are some tips for designing small extruded aluminum components?

Designing small extruded aluminum components requires careful attention to detail and a deep understanding of the extrusion process. Some tips to keep in mind include minimizing complexity wherever possible, using the right alloy for the job, and ensuring that the design can be easily extruded without causing undue stress on the material or the equipment.

It’s also important to work closely with an experienced extrusion partner who can help refine your design and identify potential issues before they become problems. With the right design and manufacturing approach, small extruded aluminum components can be a powerful tool for innovation and progress in many different industries.

In conclusion, extruded aluminum can be made small enough to meet the needs of various industries. The extrusion process allows for precise control over the dimensions of the final product, making it possible to create small and intricate shapes.

While the size of extruded aluminum depends on several factors, including the type of alloy used and the design of the die, it is possible to produce aluminum profiles as small as a few millimeters in diameter. This makes it an attractive option for applications that require lightweight components with high strength and durability.

Overall, the ability to create small extruded aluminum parts opens up a world of possibilities for engineers and designers. With the right materials and expertise, it is possible to create products that meet the most demanding specifications and deliver exceptional performance in a wide range of applications.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com