Table of Contents

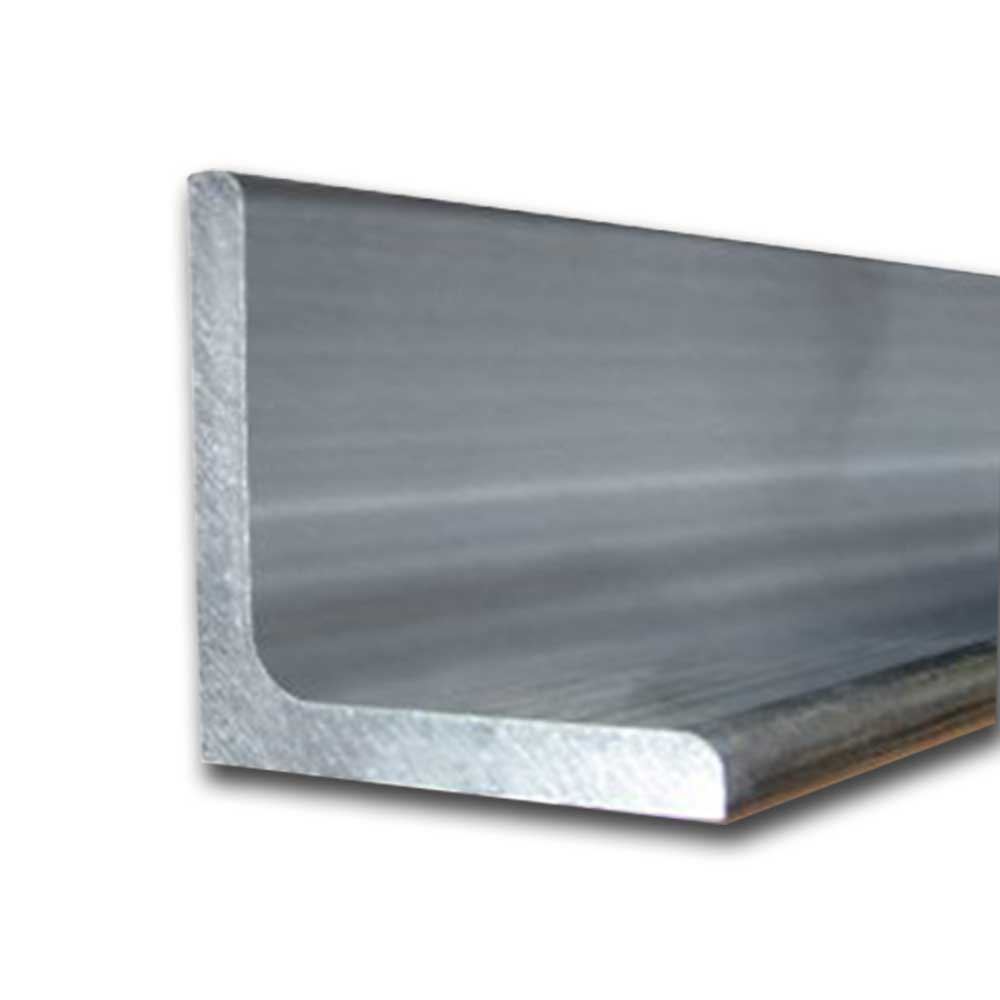

Aluminum extruded angle bars are a popular choice for structural applications due to their strength and durability. They are commonly used in construction, transportation, and manufacturing industries. However, the question remains: how strong are they really?

Aluminum extruded angle bars come in a variety of sizes and grades, each with its own unique strength properties. Understanding the strength of these bars is crucial for selecting the appropriate material for a given application. In this article, we will explore the strength of aluminum extruded angle bars and what factors contribute to their overall strength.

How Strong is Aluminum Extruded Angle Bar?

Aluminum extruded angle bar is a versatile and durable material that is commonly used in the construction industry. This type of bar can be found in various sizes, grades, and finishes, and it is known for its strength and resistance to corrosion. In this article, we will discuss the strength of aluminum extruded angle bar and its benefits.

What is Aluminum Extruded Angle Bar?

Aluminum extruded angle bar is a type of aluminum bar that is shaped like an angle. It is created through the extrusion process, where aluminum is pushed through a die to create the desired shape. The resulting bar has a 90-degree angle and can be used in various applications such as frames, supports, and decorative trims.

Benefits of Aluminum Extruded Angle Bar

One of the main benefits of aluminum extruded angle bar is its strength. It is a lightweight material that is much stronger than other metals such as steel or copper. This makes it an ideal choice for applications where weight is a concern, such as in aircraft or automotive components.

Another benefit of aluminum extruded angle bar is its resistance to corrosion. Unlike other metals, aluminum does not rust, which makes it suitable for outdoor applications. It can withstand harsh weather conditions and exposure to chemicals, making it a reliable material for construction projects.

Strength of Aluminum Extruded Angle Bar

Aluminum extruded angle bar has a high strength-to-weight ratio, which means that it can support heavy loads without adding extra weight. The strength of aluminum extruded angle bar depends on the grade and thickness of the material. Higher grade aluminum has a higher strength, while thicker bars can support more weight.

Table: Strength of Aluminum Extruded Angle Bar

| Grade | Ultimate Tensile Strength (psi) |

|——-|——————————–|

| 6061 | 45,000 |

| 6063 | 27,000 |

| 7075 | 83,000 |

As shown in the table, the ultimate tensile strength of aluminum extruded angle bar varies depending on the grade. The ultimate tensile strength is the maximum stress that the bar can withstand before breaking. Grade 7075 has the highest ultimate tensile strength, while grade 6063 has the lowest.

Uses of Aluminum Extruded Angle Bar

Aluminum extruded angle bar can be used in various applications such as:

– Frames and supports for machinery and equipment

– Structural components for buildings and bridges

– Decorative trims for furniture and fixtures

– Automotive and aircraft components

– Electrical enclosures and conduits

The versatility and strength of aluminum extruded angle bar make it a popular choice for various industries.

Aluminum Extruded Angle Bar vs. Steel Angle

Steel angle is another popular material for construction projects. However, aluminum extruded angle bar has several advantages over steel angle, such as:

– Lightweight: Aluminum extruded angle bar is much lighter than steel angle, making it easier to handle and transport.

– Corrosion-resistant: Aluminum extruded angle bar does not rust, while steel angle can corrode over time.

– Aesthetic appeal: Aluminum extruded angle bar has a smooth and shiny finish, while steel angle has a dull and rough surface.

Overall, aluminum extruded angle bar is a reliable and versatile material that can be used in various applications. Its strength, resistance to corrosion, and lightweight make it a popular choice for construction projects.

Frequently Asked Questions

Aluminum extruded angle bars are widely used in various industries due to their remarkable strength and durability. Here are some frequently asked questions about the strength of aluminum extruded angle bars.

1. How Strong is Aluminum Extruded Angle Bar?

Aluminum extruded angle bars are known for their excellent strength-to-weight ratio. They are very strong and can withstand a significant amount of weight and pressure. The exact strength of aluminum extruded angle bars depends on various factors, such as the alloy used, the temper, and the dimensions of the bar. However, in general, aluminum extruded angle bars can support a lot of weight and have a high tensile strength.

When choosing an aluminum extruded angle bar, it is essential to consider the specific application and load requirements. It is also crucial to ensure that the bar meets the necessary industry standards to ensure maximum strength and durability.

2. What Makes Aluminum Extruded Angle Bar So Strong?

Aluminum extruded angle bars are made by extruding aluminum billets through a die to create a specific shape. This process creates a solid and dense structure that makes the bar exceptionally strong. Additionally, aluminum is known for its excellent strength-to-weight ratio, making it an ideal material for applications that require strength without adding excessive weight.

The strength of aluminum extruded angle bars can also be enhanced by using different alloys and tempers. For example, 6061-T6 aluminum alloy is a popular choice for applications that require high strength and resistance to corrosion. The T6 temper is achieved by heat-treating the aluminum to increase its strength and hardness.

3. What Load Can Aluminum Extruded Angle Bar Support?

The load capacity of aluminum extruded angle bars varies depending on the size, alloy, and temper of the bar. However, in general, aluminum extruded angle bars can support a significant amount of weight. The load capacity can also be affected by the length of the bar and the way it is supported. It is essential to consult the manufacturer’s specifications and industry standards to determine the maximum load capacity for a particular application.

It is also crucial to consider the safety factor when designing structures that use aluminum extruded angle bars. The safety factor is the ratio of the maximum load capacity to the actual load applied. A higher safety factor provides added protection against catastrophic failure.

4. What Are the Advantages of Using Aluminum Extruded Angle Bar?

Aluminum extruded angle bars offer several advantages over other materials, such as steel or wood. First, they are incredibly lightweight, making them easy to handle and transport. Second, they are highly resistant to corrosion, which makes them ideal for outdoor and marine applications. Third, they are easy to fabricate and can be cut, drilled, and welded to create custom shapes and sizes. Finally, they have a high strength-to-weight ratio, making them an ideal choice for applications that require strength without adding excessive weight.

Overall, aluminum extruded angle bars are an excellent choice for a wide range of applications, from construction and manufacturing to marine and automotive industries.

5. How Can I Ensure Maximum Strength and Durability of Aluminum Extruded Angle Bar?

To ensure maximum strength and durability of aluminum extruded angle bars, it is essential to choose the right alloy, temper, and dimensions for the specific application. It is also crucial to follow industry standards and specifications for fabrication, installation, and maintenance. Regular inspection and maintenance can help identify and address any issues before they become more severe.

It is also important to consider the environment and exposure to various elements, such as moisture, heat, and UV rays. Proper coating and finishing can help protect the aluminum extruded angle bars and extend their lifespan.

In conclusion, aluminum extruded angle bar is a strong and durable material that is ideal for a range of applications. Its unique properties, such as its lightweight and corrosion-resistant nature, make it a popular choice in the construction and manufacturing industries.

Moreover, the strength of aluminum extruded angle bar can be further enhanced through various processes such as heat treatment and alloying. This allows for customization to meet specific project requirements and ensures that the material can withstand high stress and pressure.

Overall, aluminum extruded angle bar is a reliable and versatile material that is widely used in various industries. Its strength and durability make it a cost-effective and practical solution for a range of applications.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com