Table of Contents

- How to Bend a Radius in Sheet Metal: A Comprehensive Guide

- Frequently Asked Questions

- What is a radius bend in sheet metal?

- What tools are needed to create a radius bend in sheet metal?

- What are some common mistakes to avoid when creating a radius bend in sheet metal?

- What are some tips for creating a high-quality radius bend in sheet metal?

- What are some common applications for radius bends in sheet metal?

As a metal worker, you know that sheet metal can be a challenging material to work with. While it’s strong and durable, bending it to the desired shape can be tricky. However, with the right tools and techniques, you can create perfect bends and radii in your sheet metal projects.

In this guide, we’ll take you step-by-step through the process of bending a radius in sheet metal. From choosing the right tools to understanding the different types of bends, we’ll give you the knowledge and skills you need to create smooth, precise curves in your metalwork. So, whether you’re a seasoned metal worker or just starting out, let’s get started on mastering the art of bending sheet metal!

- Start by choosing the right tool for the job such as a press brake or rolling machine.

- Measure and mark the location of the bend on the sheet metal.

- Clamp the sheet metal securely in the tool.

- Apply pressure to the tool to create the bend.

- Repeat the process for any additional bends.

How to Bend a Radius in Sheet Metal: A Comprehensive Guide

Bending sheet metal can be tricky, especially if you’re trying to achieve a specific radius. But with the right tools and techniques, you can easily bend sheet metal to your desired radius. In this article, we’ll walk you through the steps on how to bend a radius in sheet metal.

Tools and Materials You’ll Need

To bend a radius in sheet metal, you’ll need the following tools and materials:

Tools:

- Sheet metal brake

- Bench vise

- Hammers (mallet and ball peen)

- Sheet metal snips

- Measuring tape

- Center punch

- Drill

- Clamps

Materials:

- Sheet metal

- Marker

Preparing the Sheet Metal

Before you start bending the sheet metal, you need to prepare it first. Here’s how:

Step 1: Measure the length of the sheet metal that you need and mark it with a marker.

Step 2: Use a sheet metal snip to cut the sheet metal to the desired length.

Step 3: Use a center punch to mark the center of the sheet metal where you want to bend the radius. This will serve as a reference point for your bend.

Bending the Radius

Now that you’ve prepared the sheet metal, it’s time to start bending the radius. Here’s how:

Step 1: Clamp the sheet metal to the bench vise at the reference point you marked earlier.

Step 2: Use a mallet hammer to gently tap the sheet metal at the reference point to create a small crease. This will make it easier to bend the radius.

Step 3: Use the sheet metal brake to bend the sheet metal to your desired radius. Start by making a small bend and then gradually increase the bend until you reach the desired radius. Make sure to keep the sheet metal clamped to the bench vise to ensure that it stays in place while bending.

Step 4: Repeat steps 1 to 3 on the other end of the sheet metal to create a symmetrical radius.

Finishing Touches

Once you’ve bent the radius, there are a few finishing touches you can do to ensure that the sheet metal looks clean and professional. Here’s how:

Step 1: Use a ball peen hammer to smooth out any bumps or imperfections in the bend.

Step 2: Use a measuring tape to ensure that the radius is the correct size.

Step 3: Drill any necessary holes or cut any necessary shapes into the sheet metal using a drill and sheet metal snips.

Benefits of Bending Sheet Metal

Bending sheet metal allows you to create a variety of shapes and designs for a multitude of applications. Here are some benefits of bending sheet metal:

- Customization: Bending sheet metal allows you to create custom shapes and designs for specific applications.

- Strength: Bending sheet metal increases its strength and makes it more durable.

- Aesthetics: Bending sheet metal can add an aesthetic appeal to your project.

Bending Sheet Metal Vs Other Materials

Bending sheet metal offers several advantages over other materials such as plastic or wood. Here are some reasons why:

- Durability: Sheet metal is more durable than plastic or wood, making it ideal for projects that require strength and longevity.

- Customization: Sheet metal can be easily customized to fit specific applications, unlike plastic or wood.

- Aesthetics: Sheet metal has a professional look and feel that can’t be achieved with plastic or wood.

Conclusion

Bending a radius in sheet metal may seem daunting at first, but with the right tools and techniques, it’s a simple process. By following the steps outlined in this article, you’ll be able to bend sheet metal to your desired radius in no time. Remember to take your time, be patient, and always wear protective gear when working with sheet metal.

Frequently Asked Questions

Sheet metal bending is a process used in manufacturing to create a variety of products, including automotive parts, appliances, and electronics. One of the key aspects of sheet metal bending is the ability to create a radius bend. Here are some common questions and answers about how to bend a radius in sheet metal.

What is a radius bend in sheet metal?

A radius bend is a type of bend in sheet metal where the material is bent along a curved line rather than a straight line. This creates a rounded edge that can be both aesthetically pleasing and functional, as it can make the sheet metal easier to handle and less likely to cause injury. Radius bends can be created using a variety of tools and techniques, depending on the thickness and type of sheet metal being used.

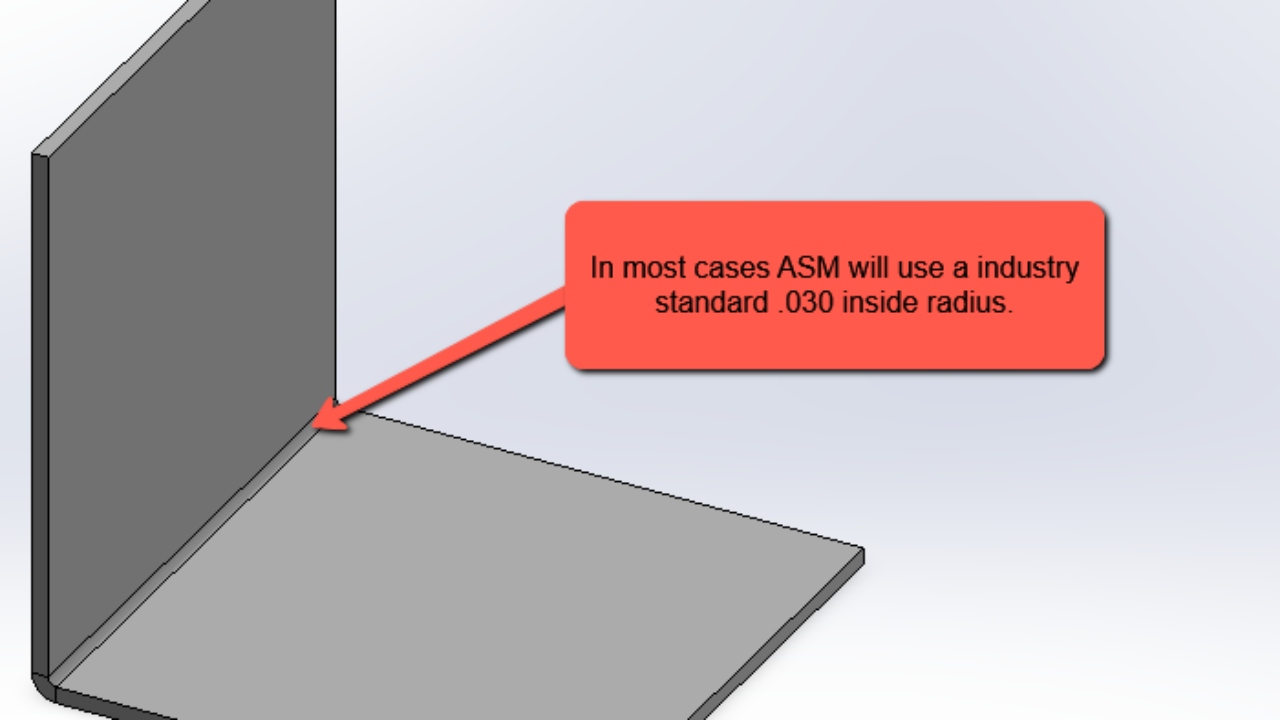

When creating a radius bend, it is important to consider the radius size and the angle of the bend. The radius size refers to the diameter of the circle along which the sheet metal is bent. The angle of the bend refers to the degree of the bend, which can range from a gentle curve to a sharp angle.

What tools are needed to create a radius bend in sheet metal?

The tools needed to create a radius bend in sheet metal will depend on the thickness and type of material being used, as well as the desired radius size and angle of the bend. Some common tools used for creating radius bends include a press brake, a slip roll machine, and a rotary draw bender. These tools allow for precise control over the bend radius and angle, and can be used to create both simple and complex shapes.

When using these tools, it is important to follow proper safety procedures and wear protective gear such as gloves and eye protection. It is also important to select the appropriate tool for the job and to ensure that the sheet metal is properly secured and supported during the bending process.

What are some common mistakes to avoid when creating a radius bend in sheet metal?

There are several common mistakes to avoid when creating a radius bend in sheet metal. One is failing to properly calculate the bend radius and angle, which can result in a bend that is too sharp or too shallow. Another common mistake is using the wrong tool for the job, which can result in an uneven bend or damage to the sheet metal.

It is also important to avoid overworking the sheet metal, as this can cause it to crack or become weak. To avoid this, it is important to use the proper amount of force and to make sure that the sheet metal is properly supported during the bending process. Finally, it is important to take the time to properly finish the bend, as this can help to ensure a smooth and even surface.

What are some tips for creating a high-quality radius bend in sheet metal?

To create a high-quality radius bend in sheet metal, it is important to start with a clean and properly prepared sheet of metal. This can help to ensure that the bend is smooth and even, and that the final product is free from defects such as cracks or dents. It is also important to select the proper tool for the job and to take the time to properly set up and secure the sheet metal before beginning the bending process.

When creating the bend, it is important to apply pressure evenly and to avoid overworking the sheet metal. It is also important to take the time to properly finish the bend, as this can help to ensure a smooth and even surface. Finally, it is important to follow proper safety procedures and to wear protective gear, such as gloves and eye protection, when working with sheet metal.

What are some common applications for radius bends in sheet metal?

Radius bends are used in a variety of applications in the manufacturing industry. One common use is in the creation of automotive parts, such as exhaust systems and fenders. Radius bends are also used in the production of appliances, such as refrigerators and washing machines, as well as in the creation of electronics, such as computer cases and audio equipment.

Radius bends can be used to create both functional and decorative elements in a variety of products, and can be used to create both simple and complex shapes. When used properly, radius bends can help to enhance the strength, durability, and visual appeal of sheet metal products.

In conclusion, bending a radius in sheet metal can be a challenging task, but with the right tools and techniques, it can be done with ease. By following the steps outlined in this guide, you can ensure that your sheet metal bends are accurate and precise.

Firstly, it is important to choose the right tools for the job. A high-quality bending machine and appropriate bending tools will make the process much smoother and more efficient. Secondly, proper preparation is key. Make sure to measure and mark your sheet metal accurately and use clamps to hold it securely in place during the bending process.

Finally, practice makes perfect. Don’t be discouraged if your first few attempts are not perfect. Take the time to refine your technique and continue to practice until you achieve the desired results. With these tips and some patience, you’ll be able to produce professional-quality sheet metal bends in no time.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com