Table of Contents

- How to Build a CNC Plasma Cutter: A Comprehensive Guide

- Step 1: Plan Your Build

- Step 2: Build the Cutting Table

- Step 3: Install the Plasma Torch

- Step 4: Install the Stepper Motors

- Step 5: Install the Control Board

- Step 6: Install the Software

- Step 7: Test and Calibrate the Machine

- Step 8: Maintenance and Upgrades

- Step 9: Safety Considerations

- Step 10: Enjoy Your CNC Plasma Cutter!

- Freequently Asked Questions

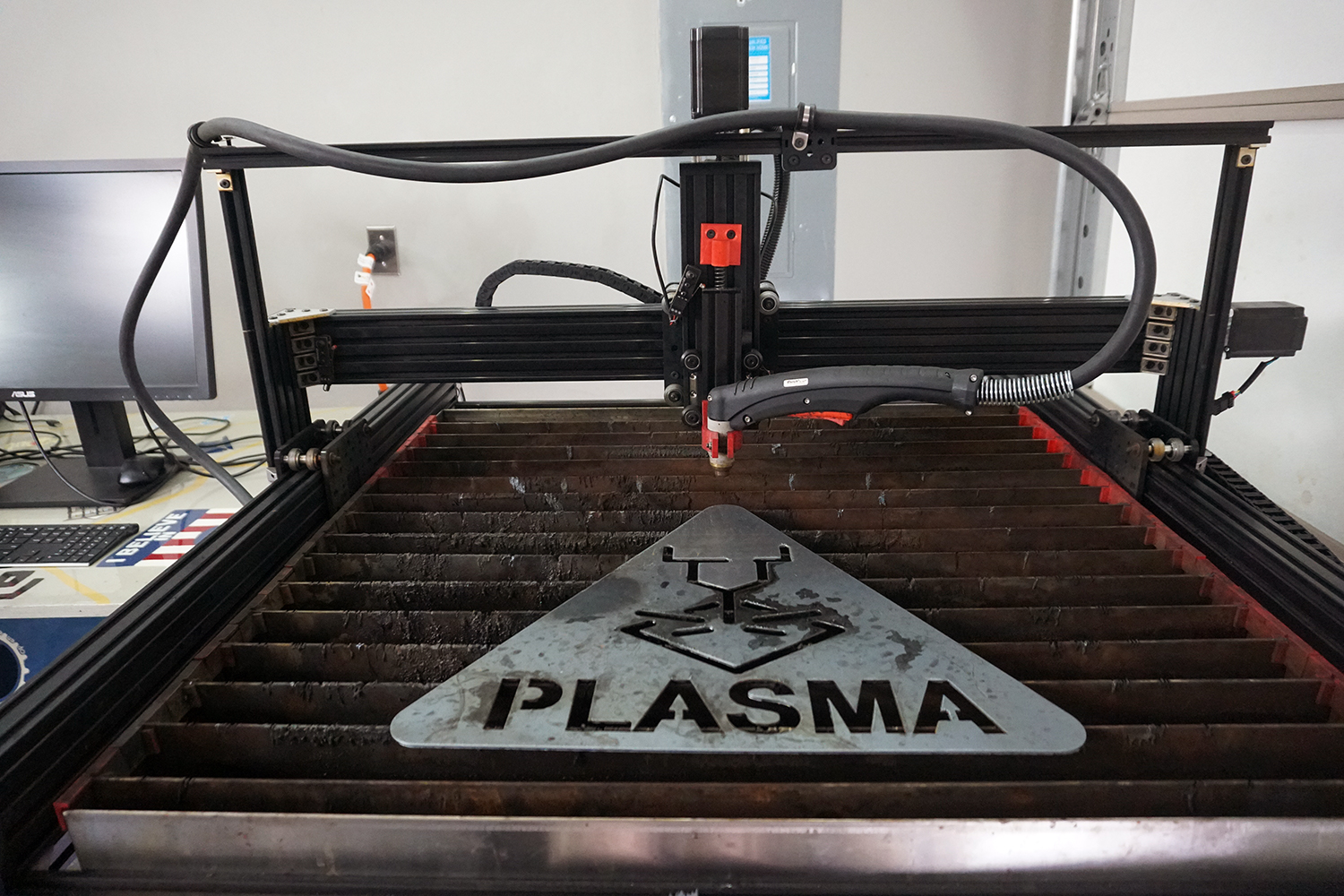

Are you looking to take your metalworking to the next level? Have you ever considered building your own CNC plasma cutter? With the right tools and knowledge, you can construct a machine that will make cutting through thick sheets of metal a breeze.

A CNC plasma cutter uses computer-controlled software to precisely cut metal with a plasma torch. While purchasing a pre-made machine can be expensive, building your own can save you money and give you the satisfaction of creating something from scratch. In this article, we will guide you through the process of building your own CNC plasma cutter, from selecting the right components to programming the machine to cut your designs.

- First, gather all the necessary components such as stepper motors, control board, plasma cutter, and power supply.

- Next, design your cutting table using CAD software and ensure it has a sturdy frame and accurate measurements.

- Install the stepper motors, control board, and power supply onto the frame and connect them using appropriate wiring.

- Attach the plasma cutter to the frame and connect it to the control board.

- Install the software and configure the settings according to your cutting needs.

- Test the machine and make any necessary adjustments before using it for production.

How to Build a CNC Plasma Cutter: A Comprehensive Guide

A CNC plasma cutter is a powerful tool that can cut through different types of materials with precision and speed. Building your own CNC plasma cutter can be a rewarding experience that saves you money and gives you complete control over the design and functionality of the machine. In this article, we will guide you through the process of building a CNC plasma cutter from scratch.

Step 1: Plan Your Build

Before you start building your CNC plasma cutter, you need to have a clear plan of what you want to achieve. First, determine the size of the machine based on the size of the materials you will be cutting. You also need to consider the type of plasma cutter you will be using, as well as the software and control system you will need to operate the machine.

Once you have a clear plan, you can start sourcing the components you need. This will include the cutting table, the plasma torch, the stepper motors, the control board, and the software.

Benefits of Building Your Own CNC Plasma Cutter

- Cost savings compared to buying a pre-built machine

- Customizable design to fit your specific needs

- Opportunity to learn new skills and gain knowledge about CNC technology

Step 2: Build the Cutting Table

The cutting table is the foundation of your CNC plasma cutter, and it is important to build it with precision to ensure accurate cuts. The cutting table should be made of a flat, rigid material such as steel, and it should be level to ensure consistent cutting depth.

Next, you will need to install a water table to reduce heat distortion and prevent damage to the machine. The water table should be made of a non-corrosive material such as PVC, and it should have a drain to remove excess water.

Table Material Comparison: Steel vs Aluminum

| Steel | Aluminum |

|---|---|

| Durable and strong | Lightweight and easy to move |

| Resistant to heat and warping | May require additional support for rigidity |

| More affordable | Higher cost due to material and manufacturing process |

Step 3: Install the Plasma Torch

The plasma torch is the cutting tool that will be used to cut through the material. It is important to choose a high-quality torch that is compatible with your CNC system. The torch should be mounted on a torch holder that can be adjusted for height and angle.

Plasma Cutter Comparison: Hypertherm vs Thermal Dynamics

- Hypertherm: Known for its reliability and precision cutting

- Thermal Dynamics: Offers a wide range of cutting options for different materials

Step 4: Install the Stepper Motors

The stepper motors are responsible for moving the cutting torch along the X, Y, and Z axes. They should be high-quality, reliable motors that can handle the weight of the torch and the cutting head. The motors should be mounted securely to the cutting table, and they should be wired to the control board.

Stepper Motor Comparison: NEMA 23 vs NEMA 34

| NEMA 23 | NEMA 34 |

|---|---|

| Lower cost | Higher torque and speed |

| Smaller size | Larger size and weight |

| Suitable for smaller machines | Suitable for larger machines and heavy-duty cutting |

Step 5: Install the Control Board

The control board is the brain of the CNC plasma cutter, and it is responsible for interpreting the instructions from the software and controlling the movement of the motors. The control board should be compatible with your software and should be mounted on the cutting table for easy access.

Control Board Comparison: Mach3 vs LinuxCNC

- Mach3: Windows-based software with a user-friendly interface

- LinuxCNC: Open-source software with advanced features and customization options

Step 6: Install the Software

The software is the interface that you will use to design your cuts and control the machine. There are many software options available, ranging from basic to advanced. The software should be compatible with your control board and should be easy to use.

Software Comparison: SheetCAM vs Fusion 360

| SheetCAM | Fusion 360 |

|---|---|

| Designed specifically for CNC plasma cutting | Offers a wide range of design and modeling tools |

| Easy to use and learn | Requires more advanced knowledge of CAD design |

| Low cost | Higher cost due to advanced features |

Step 7: Test and Calibrate the Machine

Once all the components are installed, you need to test and calibrate the machine to ensure it is functioning properly. This will involve running test cuts and adjusting the settings as needed to achieve the desired results. It is important to take your time with this step to avoid any issues down the line.

Common Calibration Issues and Solutions

- Uneven cutting depth: Adjust the torch height and check for level cutting table

- Slower than expected cutting speed: Check for correct motor and software settings

- Excessive smoke or slag: Adjust amperage and air pressure settings on the plasma cutter

Step 8: Maintenance and Upgrades

Regular maintenance is key to keeping your CNC plasma cutter in top condition. This will involve cleaning and lubricating the moving parts, checking for wear and tear, and replacing any damaged components. You may also want to consider upgrades such as adding a THC (torch height control) system or upgrading to a more powerful plasma cutter.

Benefits of Upgrading to a THC System

- Improved cutting accuracy and consistency

- Reduced risk of torch damage and wear

- Ability to cut thicker materials with ease

Step 9: Safety Considerations

It is important to consider safety when building and operating a CNC plasma cutter. Always wear protective gear such as gloves, safety glasses, and a face shield. Keep the work area clean and free of debris, and never leave the machine unattended while it is in operation.

Common Safety Hazards and Precautions

- Electrical shock: Always disconnect power before making any adjustments or repairs

- Fire and explosion: Keep flammable materials away from the machine and follow proper plasma cutter safety guidelines

- Eye and skin damage: Wear appropriate protective gear and avoid looking directly at the plasma arc

Step 10: Enjoy Your CNC Plasma Cutter!

Building a CNC plasma cutter can be a challenging but rewarding experience. With proper planning, installation, and maintenance, you can enjoy the benefits of a powerful cutting tool that gives you complete control over your projects. Whether you are a hobbyist or a professional, a CNC plasma cutter is a valuable addition to any workshop.

Freequently Asked Questions

Building a CNC plasma cutter can be a daunting task, but with the right knowledge and guidance, it can be an enjoyable and rewarding experience. Here are some frequently asked questions and answers to help you get started.

What is a CNC plasma cutter?

A CNC plasma cutter is a computer-controlled machine that uses a plasma torch to cut metal. The machine is programmed to move the torch in a specific pattern to cut out shapes and designs. This machine is commonly used in metal fabrication shops, automotive repair shops, and other industries that require precise and efficient cutting of metal.

Building your own CNC plasma cutter can be a cost-effective option for those who need a machine for personal or small business use. However, it requires some technical expertise and knowledge of electrical and mechanical systems.

What are the advantages of building your own CNC plasma cutter?

Building your own CNC plasma cutter has several advantages. Firstly, you can customize the machine to meet your specific needs and requirements. You can choose the size of the cutting table, the power of the plasma torch, and the type of control system you want to use. Secondly, building your own machine can save you money compared to buying a pre-built machine. Finally, building your own machine can be a fun and rewarding experience that allows you to learn new skills and gain confidence in your abilities.

However, it is important to note that building your own CNC plasma cutter requires a significant investment of time and money. You will need to purchase or fabricate many of the components, and you will need to have some technical knowledge to assemble and program the machine.

What are the basic components of a CNC plasma cutter?

A CNC plasma cutter consists of several components, including a cutting table, a plasma torch, a power supply, a control system, and software. The cutting table is typically made of steel and is designed to hold the metal being cut. The plasma torch is the tool that actually cuts the metal, and it is attached to a Z-axis that moves the torch up and down. The power supply provides the electrical current needed to generate the plasma arc. The control system is responsible for moving the torch in a specific pattern to cut out the desired shape. Finally, the software is used to design the part to be cut and to generate the code that controls the machine.

Building your own CNC plasma cutter requires sourcing or fabricating all of these components and assembling them into a functional machine. It also requires the ability to program the control system and software to produce accurate cuts.

What are some tips for building a CNC plasma cutter?

Building a CNC plasma cutter can be a complex and challenging project, but with the right approach, it can be a rewarding experience. Here are some tips to help you get started:

1. Research and plan: Before starting your build, research the components you will need and plan out the design of your machine. Make sure you have a clear understanding of the technical requirements and the costs involved.

2. Source quality components: To ensure that your machine is reliable and produces accurate cuts, source high-quality components. Don’t skimp on components like the plasma torch, power supply, and control system.

3. Test as you go: As you assemble your machine, test each component as you go to ensure that it is functioning properly. This will help you catch any issues early and avoid costly mistakes later on.

4. Take safety precautions: A CNC plasma cutter can be a dangerous machine if not used properly. Make sure you take all necessary safety precautions, including wearing protective gear and following proper procedures for operating the machine.

What are some common problems when building a CNC plasma cutter?

Building a CNC plasma cutter can be a complex project, and there are several common problems that builders may encounter. Some of these include:

1. Electrical issues: Building a CNC plasma cutter requires a good understanding of electrical systems. Issues like wiring problems, voltage drops, and grounding issues can cause problems with the machine’s operation.

2. Mechanical issues: The mechanical components of a CNC plasma cutter must be precisely aligned and calibrated to produce accurate cuts. Issues like backlash, misaligned components, and worn bearings can cause problems with the machine’s performance.

3. Software issues: The software used to control a CNC plasma cutter can be complex, and issues like incorrect code or improper calibration can cause problems with the machine’s operation.

4. Safety issues: A CNC plasma cutter can be a dangerous machine if not used properly. Issues like insufficient ventilation, improper grounding, and failure to follow safety procedures can pose a risk to the operator.

By understanding these common problems and taking steps to address them, you can increase your chances of building a successful and reliable CNC plasma cutter.

In conclusion, building a CNC plasma cutter can be a challenging yet rewarding project. With the right equipment, knowledge and skills, you can create a machine that can cut through various materials with precision and speed.

It is important to keep in mind that safety should always be a top priority when building and operating a CNC plasma cutter. Make sure to take all necessary precautions and follow manufacturer’s instructions to prevent accidents and injuries.

Finally, don’t be afraid to experiment and make adjustments to your machine as you go along. Building a CNC plasma cutter is a continuous learning process, and there is always room for improvement. With patience and persistence, you can create a machine that meets your specific needs and helps you achieve your goals.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com