Table of Contents

Are you new to CNC turning and struggling with calculating RPM? Worry not! RPM, or revolutions per minute, is a critical parameter in CNC turning, and knowing how to calculate it accurately can make all the difference in your machining operations. In this article, we will guide you through the process of calculating RPM in CNC turning, covering everything from the basic formula to factors that can affect the RPM value. So, let’s dive in and get you up to speed on RPM calculations!

- Determine the cutting speed of the material being used in surface feet per minute (SFM).

- Convert the SFM to meters per minute (MPM) by multiplying by 0.3048.

- Calculate the diameter of the cutting tool in inches.

- Divide the SFM by the product of pi and the tool diameter in inches to find the spindle speed in revolutions per minute (RPM).

How to Calculate RPM in CNC Turning?

CNC turning is a process that involves the removal of material from a workpiece to create a desired shape or form. The speed at which the workpiece rotates is an important factor in CNC turning. RPM or Revolutions Per Minute is a measure of the rotational speed of the workpiece. Calculating RPM is an essential aspect of CNC turning, and in this article, we will discuss how to calculate RPM in CNC turning.

What is RPM?

RPM stands for Revolutions per Minute, and it is a measure of the rotational speed of the workpiece. It indicates how many times the workpiece rotates in a minute. RPM is an essential factor in CNC turning as it determines the cutting speed and the quality of the final product.

To calculate RPM, you need to know the cutting speed and the diameter of the workpiece. The cutting speed is the speed at which the cutting tool moves across the workpiece, and it is measured in feet per minute (FPM) or meters per minute (MPM). The diameter of the workpiece is the distance from one end of the workpiece to the other end, passing through the center.

Formula to Calculate RPM

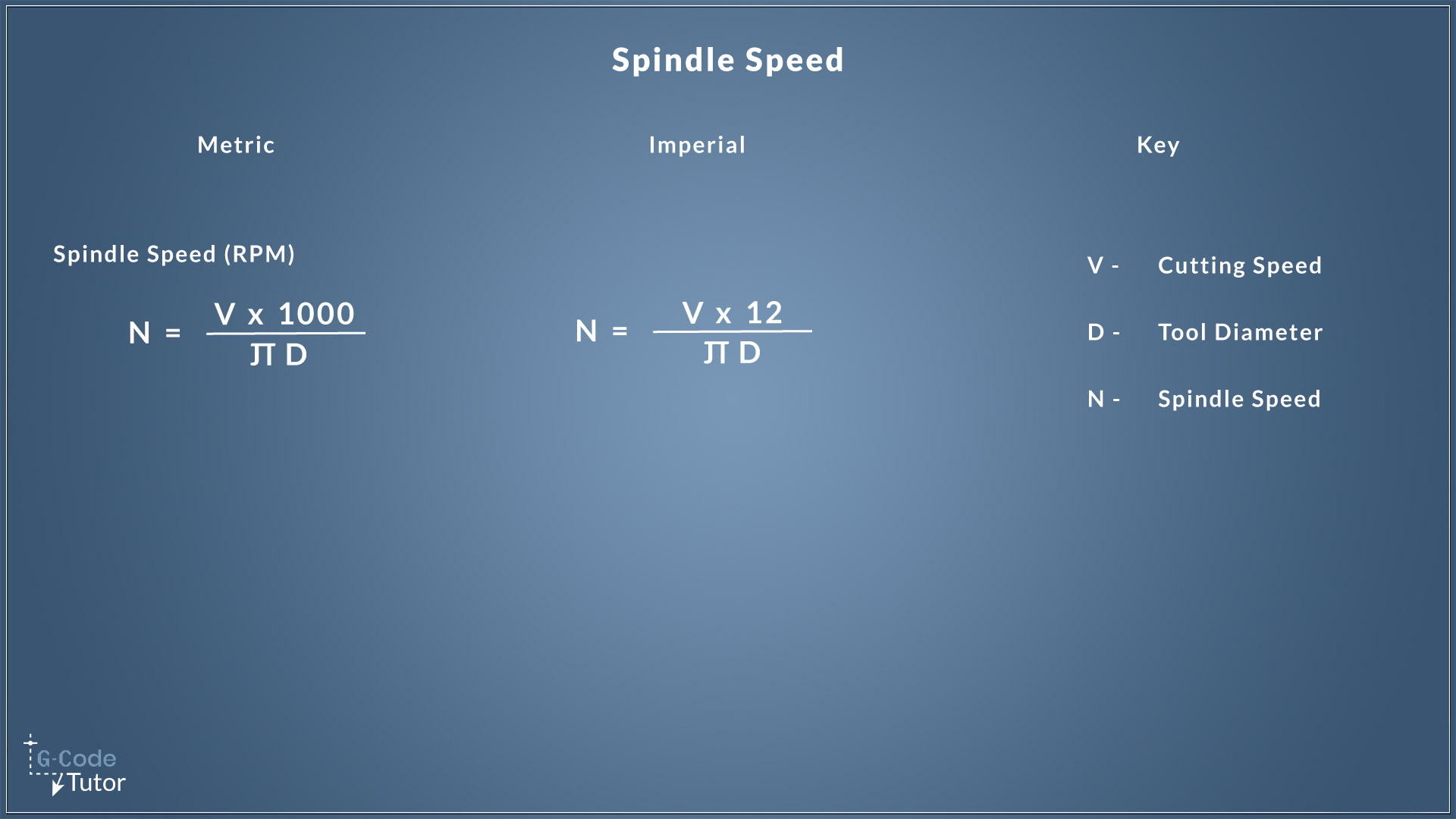

The formula to calculate RPM is as follows:

RPM = (Cutting Speed x 4) / Diameter

Example

Let’s take an example to understand the calculation of RPM. Suppose the cutting speed is 100 FPM, and the diameter of the workpiece is 10 inches. Using the formula, we can calculate the RPM as follows:

RPM = (100 x 4) / 10

RPM = 40

Therefore, the RPM of the workpiece is 40.

Benefits of Calculating RPM

Calculating RPM is essential in CNC turning for various reasons. Firstly, it helps to determine the cutting speed and the quality of the final product. If the RPM is too high, the cutting tool may not be able to cut the material effectively, and the final product may have a poor finish. On the other hand, if the RPM is too low, the cutting tool may wear out quickly, resulting in the need for frequent tool changes.

Secondly, calculating RPM helps to optimize the cutting process, resulting in increased efficiency and reduced production time. By adjusting the RPM, the cutting speed can be optimized, resulting in faster material removal and reduced production time.

RPM vs Surface Speed

The surface speed is another measure of the cutting speed and is measured in FPM or MPM. It indicates the speed at which the cutting tool moves across the workpiece’s surface. RPM and surface speed are related, and they can be used interchangeably in some cases.

However, RPM is a more accurate measure of the cutting speed as it takes into account the workpiece’s diameter. For instance, two workpieces with the same surface speed but different diameters will have different RPMs. Therefore, it is essential to calculate RPM to ensure the cutting speed is optimized for each workpiece.

Conclusion

Calculating RPM is an essential aspect of CNC turning, and it helps to optimize the cutting process and improve the quality of the final product. By using the formula and considering the cutting speed and the diameter of the workpiece, you can calculate the RPM accurately. With the correct RPM, you can achieve the desired finish, reduce production time, and increase efficiency.

Frequently Asked Questions

In this section, we will answer some common questions related to calculating RPM in CNC turning.

What is RPM in CNC Turning?

RPM stands for “Revolutions Per Minute,” which is a measure of how quickly a CNC turning tool rotates. It is an essential factor in determining the cutting speed necessary for a specific material.

To calculate RPM, you need to know the cutting speed (in meters per minute) and the diameter of the tool. By using a mathematical formula that takes into account these two variables, you can determine the necessary RPM for your CNC turning operation.

Why is RPM Important in CNC Turning?

RPM is a critical factor in determining the cutting speed necessary for a specific material. By adjusting the RPM, you can achieve the optimal cutting speed, which ensures that the material is cut efficiently and effectively.

Additionally, RPM can help you avoid tool wear and tool breakage. If the RPM is too high, the tool can wear out quickly, leading to a decrease in the quality of the cut. On the other hand, if the RPM is too low, the tool can break, which can be dangerous and costly.

What Factors Affect RPM in CNC Turning?

Several factors can affect the RPM in CNC turning, including the material being cut, the diameter of the tool, and the cutting speed. The material being cut will determine the ideal cutting speed, which will then impact the RPM necessary to achieve that speed.

Additionally, the diameter of the tool will impact the RPM needed to achieve the optimal cutting speed. A larger diameter tool will require a lower RPM, while a smaller diameter tool will require a higher RPM.

How Do You Calculate RPM in CNC Turning?

Calculating RPM in CNC turning requires knowledge of the cutting speed and the diameter of the tool. The mathematical formula used to determine RPM is RPM = (cutting speed x 1000) / (pi x diameter of the tool).

To use this formula, you will need to convert the cutting speed to meters per minute and the diameter of the tool to millimeters. Once you have these values, you can plug them into the formula to calculate the necessary RPM.

What is the Ideal RPM for CNC Turning?

The ideal RPM for CNC turning will depend on several factors, including the material being cut, the diameter of the tool, and the cutting speed. In general, the optimal RPM is the one that achieves the ideal cutting speed for the material being cut while also avoiding tool wear and breakage.

To determine the ideal RPM, you will need to consider these factors and use the mathematical formula discussed earlier to calculate the necessary RPM. It may take some trial and error to find the optimal RPM for your specific CNC turning operation.

In conclusion, calculating RPM in CNC turning is an essential skill that every machinist should master. By understanding the relationship between spindle speed, cutting speed, and tool diameter, you can optimize your machining process and achieve maximum efficiency and accuracy.

Remember to always refer to the manufacturer’s specifications for your machine and tools, and use a reliable RPM calculator to ensure you’re getting accurate results. Don’t be afraid to experiment and adjust your settings as needed to achieve the best possible outcome.

With a little practice and attention to detail, you’ll soon be able to confidently calculate RPM in CNC turning like a pro. So go ahead and give it a try – your CNC projects will thank you for it!

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com