Table of Contents

Paragraph 1:

Backlash is an issue that commonly occurs in CNC machines. It is the slack between the gears that can lead to inaccuracies in your machine’s movements. As a CNC operator, it’s essential to check backlash regularly to maintain the precision and quality of your work. In this article, we will guide you through how to check backlash in CNC machines, so you can ensure your machine is running smoothly and producing high-quality output.

Paragraph 2:

Checking backlash in a CNC machine is a crucial part of machine maintenance. It’s a simple process that can save you time and money in the long run by preventing inaccuracies and reducing the risk of machine failure. Whether you’re a seasoned professional or a beginner, understanding how to check backlash in your CNC machine is essential for achieving the best possible results. So, let’s dive into the process and get your machine running like a well-oiled machine!

To check the backlash in a CNC machine, follow these steps:

- Securely clamp a dial indicator to the machine’s spindle.

- Position the indicator’s needle against the machine’s table or vice.

- Move the spindle back and forth and note the indicator’s readings.

- Reverse the indicator’s position and repeat the process.

- Compare the readings from both directions, and the difference between them is the backlash value.

How to Check Backlash in CNC Machine: A Comprehensive Guide

What is CNC Machine Backlash?

CNC machines are precision tools that use computer programs and automation to perform various tasks. However, due to the mechanical nature of these machines, a certain amount of play, or backlash, can occur between the machine’s moving parts. Backlash can affect the accuracy and precision of the machine, leading to errors in the final product. Therefore, it is essential to regularly check CNC machine backlash to ensure optimal performance.

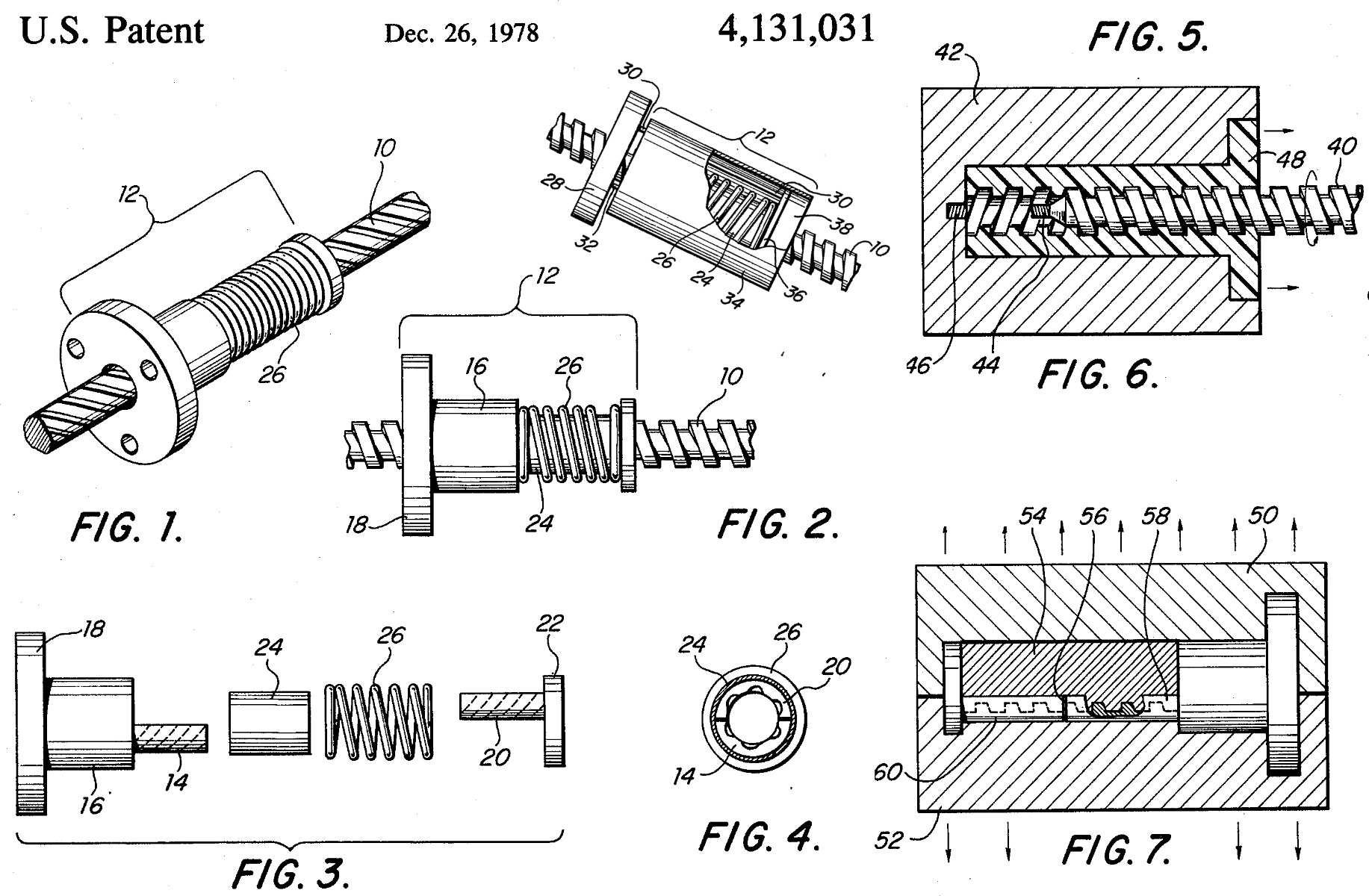

Backlash can occur in different parts of the CNC machine, such as the ball screw, linear guides, and gears. The most common cause of backlash is wear and tear on the machine’s components, which can cause them to loosen over time. Other factors that can cause backlash include improper installation, poor maintenance, and environmental factors such as temperature changes and vibration.

Tools Required for Checking Backlash

Before starting the process of checking the backlash in your CNC machine, you will need to gather some tools. The tools you need will depend on the type of machine you have and the specific components you want to check. However, some common tools you may need include:

- Calipers or micrometers

- Dial indicators

- Wrenches or pliers

- Allen keys or screwdrivers

- Clean cloth or paper towel

- Pen and paper for recording measurements

Steps for Checking Backlash in CNC Machine

Checking the backlash in your CNC machine involves several steps. Here is a step-by-step guide on how to check backlash in your CNC machine:

- Identify the component you want to check for backlash. This could be the ball screw, linear guides, or gears.

- Remove any covers or guards that may be obstructing your access to the component.

- Using a clean cloth or paper towel, wipe the component clean of any dirt or debris.

- Attach the dial indicator to the component, making sure it is perpendicular to the direction of movement.

- Zero the dial indicator to the starting position.

- Move the component in one direction, taking note of the reading on the dial indicator.

- Reverse the direction of movement and note the reading on the dial indicator.

- Calculate the difference between the two readings. This will give you the amount of backlash in the component.

- Repeat the process for other components you want to check.

- Record your measurements for future reference.

Benefits of Checking Backlash in CNC Machine

Regularly checking the backlash in your CNC machine offers several benefits, including:

- Ensuring accuracy and precision in your final product

- Reducing the risk of errors and defects in your products

- Increasing the lifespan of your machine’s components

- Improving the overall performance of your CNC machine

Backlash vs. Accuracy

Backlash and accuracy are two important factors that affect the performance of your CNC machine. While backlash refers to the play or looseness between the machine’s moving parts, accuracy refers to the machine’s ability to perform tasks precisely and consistently. Too much backlash can result in reduced accuracy and precision, leading to errors in the final product. Therefore, it is essential to regularly check and correct any backlash in your CNC machine to maintain optimal accuracy and precision.

Conclusion

Checking the backlash in your CNC machine is an essential maintenance task that helps ensure optimal performance and accuracy. By following the steps outlined in this guide and regularly checking for backlash, you can reduce the risk of errors and defects in your products, increase the lifespan of your machine’s components, and improve the overall performance of your CNC machine.

Frequently Asked Questions

Below are some frequently asked questions about how to check backlash in a CNC machine.

What is Backlash in a CNC Machine?

Backlash is the amount of play or clearance between the mating parts that should be in contact with each other but are not. In a CNC machine, backlash can occur between the lead screw and the nut, the ball screw and the nut, or the rack and pinion.

Backlash can result in poor part accuracy, reduced repeatability, and increased wear on the machine components. It is important to periodically check and adjust backlash to maintain machine performance.

How to Check Backlash in a CNC Machine?

One way to check backlash in a CNC machine is to use a dial indicator. Attach the dial indicator to the machine table and zero it out. Move the table in one direction and note the reading on the dial indicator. Then, move the table in the opposite direction and note the reading again. The difference between the two readings is the backlash.

Another method is to use a laser interferometer. This method is more accurate than using a dial indicator but requires specialized equipment. The laser interferometer measures the actual position of the machine components and can detect small amounts of backlash.

How Often Should Backlash be Checked in a CNC Machine?

The frequency of backlash checks depends on the machine usage and the manufacturer’s recommendations. Generally, backlash should be checked at least once a year or whenever the machine undergoes major repairs or modifications. It is also recommended to check backlash before and after performing any critical machining operations.

If the machine is used heavily or operates in harsh conditions, more frequent checks may be necessary. Regular maintenance and lubrication can help reduce the amount of backlash and prolong the life of the machine components.

How to Adjust Backlash in a CNC Machine?

The method for adjusting backlash depends on the machine type and manufacturer. Some machines have built-in mechanisms for adjusting backlash, while others require manual adjustments. Consult the machine’s manual or contact the manufacturer for specific instructions on how to adjust backlash.

In general, adjusting backlash involves tightening or loosening the components that cause the play or clearance. It is important to make small adjustments and recheck the backlash until it falls within the manufacturer’s recommended range.

What are the Consequences of Ignoring Backlash in a CNC Machine?

Ignoring backlash in a CNC machine can result in poor part accuracy, reduced repeatability, and increased wear on the machine components. These consequences can lead to scrapped parts, increased production costs, and machine downtime.

Over time, ignoring backlash can also lead to permanent damage to the machine components, which can be costly to repair or replace. It is important to periodically check and adjust backlash to maintain machine performance and prolong its lifespan.

In conclusion, checking backlash in a CNC machine is a crucial step to ensure the accuracy and precision of your machine. The process may seem daunting at first, but with the right tools and techniques, it can be done quickly and easily.

To begin the process, make sure you have a dial indicator and a magnetic base. Next, set the indicator to zero and move the machine’s axis in one direction. Then, move the axis in the opposite direction and note the reading on the indicator. This reading will tell you the amount of backlash present in the machine.

Remember to repeat this process for each axis of the machine, and to adjust the backlash if necessary. With these steps, you can ensure your CNC machine is operating at its full potential and producing high-quality work.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com