Are you in the market for a CNC router but feeling overwhelmed by the options available? Choosing the right CNC router can be a daunting task, especially for those new to the industry. But fear not, as this guide will provide you with the knowledge and tools necessary to make an informed decision.

In this article, we will discuss the key factors to consider when selecting a CNC router, including size, power, and price. By the end of this guide, you will have a better understanding of what to look for in a CNC router and be well on your way to finding the perfect machine for your needs. So let’s get started!

How to Choose a CNC Router?

- Consider the size of the machine and the size of the material you will be working with.

- Think about the power and speed capabilities you will need for your specific projects.

- Research the types of cutting tools and accessories that are compatible with the machine.

- Determine if you need a machine with a manual or automatic tool changer.

- Look for a machine with user-friendly software and control capabilities.

- Consider the level of customer support and training offered by the manufacturer.

Choosing the Right CNC Router: A Beginner’s Guide

If you are in the market for a CNC router, you may feel overwhelmed by the sheer number of options available. However, choosing the right one for your needs is crucial to achieving the best results. In this article, we will guide you through the process of selecting a CNC router that suits your specific requirements.

1. Know Your Material

The first step in selecting a CNC router is to determine the type of material you will be working with. Different materials require different types of routers, and using the wrong one can result in subpar results or even damage to the machine. Some common materials include wood, plastic, metal, and foam.

When choosing a CNC router, consider the material’s thickness, density, and hardness. For example, a wood router is not suitable for cutting metal, while a metal router may not handle wood as well. Ensure that the router you choose can handle the specific material and thickness you will be working with.

2. Consider the Work Area

The size of your work area is another crucial factor to consider when choosing a CNC router. The work area refers to the maximum size of material that the machine can accommodate. If you plan on working with large materials, such as sheets of plywood, you will need a CNC router with a larger work area.

Keep in mind that larger work areas typically come with a higher price tag, so it’s important to balance your needs with your budget.

3. Decide on the Type of CNC Router

There are three main types of CNC routers: hobbyist, industrial, and production. Hobbyist routers are small and affordable, designed for personal use. Industrial routers are larger and more expensive, designed for commercial use. Production routers are the largest and most expensive, designed for high-volume production.

Consider the type of work you will be doing and your budget when deciding on the type of CNC router.

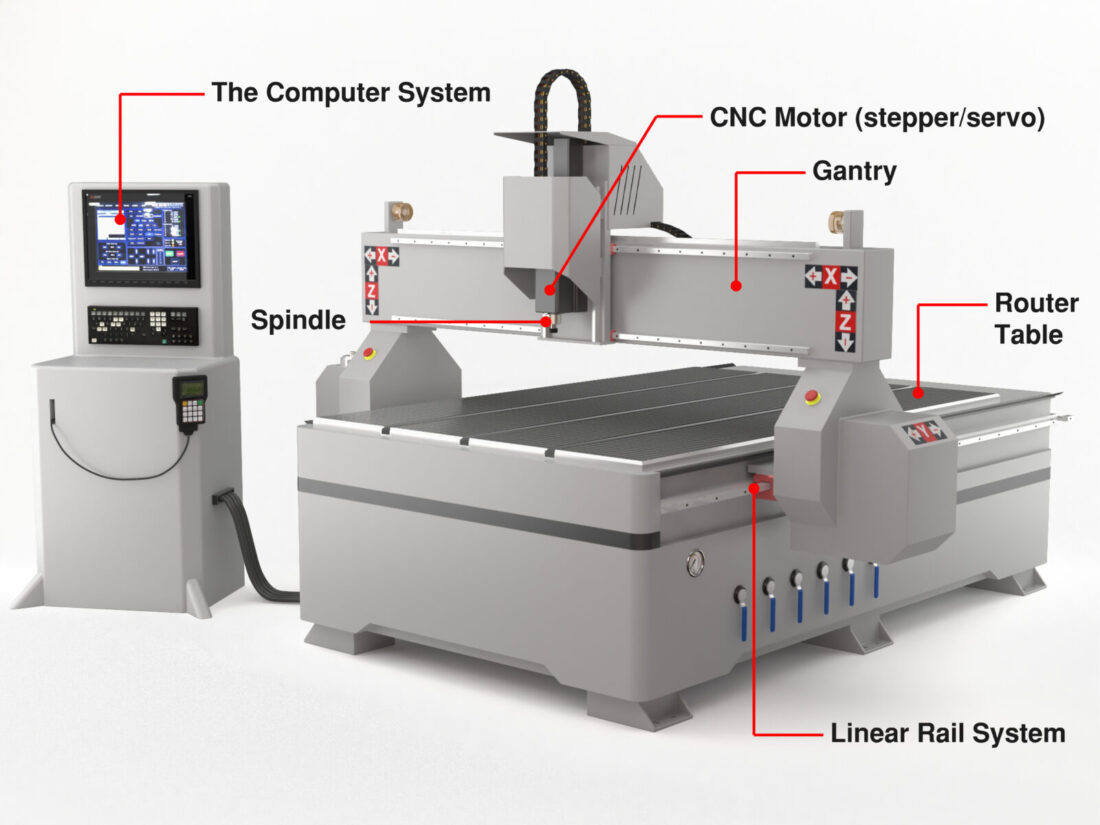

4. Look at the Spindle

The spindle is the part of the CNC router that spins the cutting tool. The spindle’s power and speed are essential factors that affect the router’s performance. Look for a CNC router with a spindle that can handle the material you will be working with.

A high-power spindle can cut through dense materials like metal quickly, while a low-power spindle is suitable for softer materials like wood.

5. Check the Accuracy and Precision

The accuracy and precision of a CNC router are crucial to achieving high-quality results. The router’s accuracy refers to how close the machine can cut to the programmed path, while precision refers to how consistently the machine can cut.

Look for a CNC router with a high accuracy and precision rating to achieve the best results.

6. Consider the Software

The software that comes with the CNC router is just as important as the machine itself. Look for software that is user-friendly and intuitive, with features that match your needs. Some software may also allow for customization, which can be useful if you have specific requirements.

7. Look at the Price

CNC routers can range in price from a few hundred dollars to tens of thousands of dollars. Consider your budget and the features you need when selecting a CNC router. Keep in mind that a higher price tag may come with additional features and higher quality materials.

8. Check for Customer Support

Customer support is an essential factor to consider when choosing a CNC router. Look for a manufacturer that provides reliable customer support and technical assistance. Some manufacturers may also offer training programs or online resources to help you get the most out of your CNC router.

9. Read Reviews

Reading reviews from other users can provide valuable insight into the performance and reliability of a CNC router. Look for reviews from users who have similar needs and requirements as you. Pay attention to any common issues or complaints that may affect your decision.

10. Choose a Reputable Manufacturer

Lastly, choose a reputable manufacturer when selecting a CNC router. Look for a manufacturer with a proven track record of producing high-quality, reliable machines. Consider the warranty and return policy when making your decision.

In conclusion, choosing the right CNC router requires careful consideration of the material, work area, type, spindle, accuracy, software, price, customer support, reviews, and manufacturer. By following these guidelines and doing your research, you can select a CNC router that meets your needs and delivers exceptional results.

Freequently Asked Questions

What factors should be considered when choosing a CNC router?

When choosing a CNC router, there are several factors to consider. First, consider the size of the machine and the size of the material you will be cutting. It is important to choose a machine that can accommodate the size of your material. Next, consider the type of material you will be cutting, as different materials require different types of cutting tools. You should also consider the speed and accuracy of the machine, as well as the level of automation and ease of use. Finally, consider the price and any additional features or services that may be included.

When choosing a CNC router, it is important to carefully evaluate your needs and the capabilities of the machine. Consider factors such as the size and material of your workpieces, as well as the speed and accuracy of the machine. Additionally, think about the level of automation and ease of use you require. Ultimately, the right CNC router for your business will depend on your specific needs and budget.

What are the different types of CNC routers?

There are several different types of CNC routers available, each with its own unique capabilities and features. Some of the most common types of CNC routers include gantry routers, tabletop routers, and handheld routers. Gantry routers are large, industrial machines that are typically used for cutting large pieces of material, while tabletop routers are smaller, more portable machines that are ideal for smaller-scale work. Handheld routers are designed for more precise work, such as engraving or carving.

When choosing a CNC router, it is important to consider the type of work you will be doing and the capabilities of each machine. Gantry routers are ideal for large-scale work, while tabletop and handheld routers are better suited for smaller-scale projects. Additionally, consider the level of automation and ease of use you require, as well as any additional features or services that may be included.

What types of materials can be cut with a CNC router?

CNC routers can be used to cut a wide variety of materials, including wood, plastic, metal, and composites. The type of material you can cut with a CNC router will depend on the type of cutting tool being used and the capabilities of the machine. For example, some machines may be better suited for cutting hard materials such as metal, while others may be better suited for softer materials such as wood.

When choosing a CNC router, it is important to consider the type of material you will be cutting and the capabilities of the machine. Different types of materials may require different cutting tools, so it is important to choose a machine that can accommodate your specific needs.

What is the difference between a 3-axis and 5-axis CNC router?

A 3-axis CNC router is a machine that can move in three directions: up and down, left and right, and forward and backward. This type of machine is ideal for cutting flat or simple three-dimensional shapes. A 5-axis CNC router, on the other hand, can move in five directions: up and down, left and right, forward and backward, as well as rotate around two additional axes. This type of machine is ideal for cutting complex shapes and contours.

When choosing a CNC router, it is important to consider the type of work you will be doing and the capabilities of the machine. If you will be cutting simple shapes or working with flat materials, a 3-axis machine may be sufficient. However, if you will be working with complex shapes or multi-sided parts, a 5-axis machine may be necessary.

What should be considered when purchasing a used CNC router?

When purchasing a used CNC router, there are several factors to consider. First, evaluate the condition of the machine and the quality of the parts. Look for signs of wear and tear, and ask about any repairs or maintenance that has been performed. Next, consider the age of the machine and whether it is still supported by the manufacturer. You should also evaluate the level of customer support and training that is available.

When purchasing a used CNC router, it is important to do your research and carefully evaluate the machine’s condition and capabilities. Consider factors such as the age of the machine, the manufacturer’s support, and the level of customer support and training that is available. Ultimately, the right used CNC router will depend on your specific needs and budget.

In conclusion, choosing the right CNC router for your business is crucial to ensure smooth operations and quality output. With so many options available in the market, it can be overwhelming to make a decision. However, by considering your specific needs and requirements, researching the features and capabilities of different routers, and evaluating the reputation and customer support of the manufacturer, you can make an informed choice.

Investing in a CNC router can be a significant expense, but it can also bring numerous benefits to your business, such as increased productivity, precision, and versatility. Therefore, it is important not to rush into a decision and take the time to evaluate your options thoroughly.

Ultimately, the CNC router you choose should align with your business goals, budget, and production demands. By following the tips and guidelines outlined in this article, you can make a wise investment that will pay off in the long run.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com