Table of Contents

- How to Choose a CNC Spindle?

- 1. Determine the Type of Cutting You Will Perform

- 2. Consider the Material You Will Be Cutting

- 3. Look at the Spindle’s Power and Speed

- 4. Check the Spindle’s Torque

- 5. Look at the Spindle’s Cooling System

- 6. Consider the Spindle’s Noise Level

- 7. Look at the Spindle’s Size and Weight

- 8. Check the Spindle’s Durability

- 9. Consider the Spindle’s Manufacturer

- 10. Look at the Spindle’s Price

- Frequently Asked Questions

- What are the most important factors to consider when choosing a CNC spindle?

- What is the difference between an air-cooled and a water-cooled spindle?

- What is the difference between a belt-driven and a direct-drive spindle?

- What is the maximum RPM that a CNC spindle can achieve?

- What is the best way to maintain a CNC spindle?

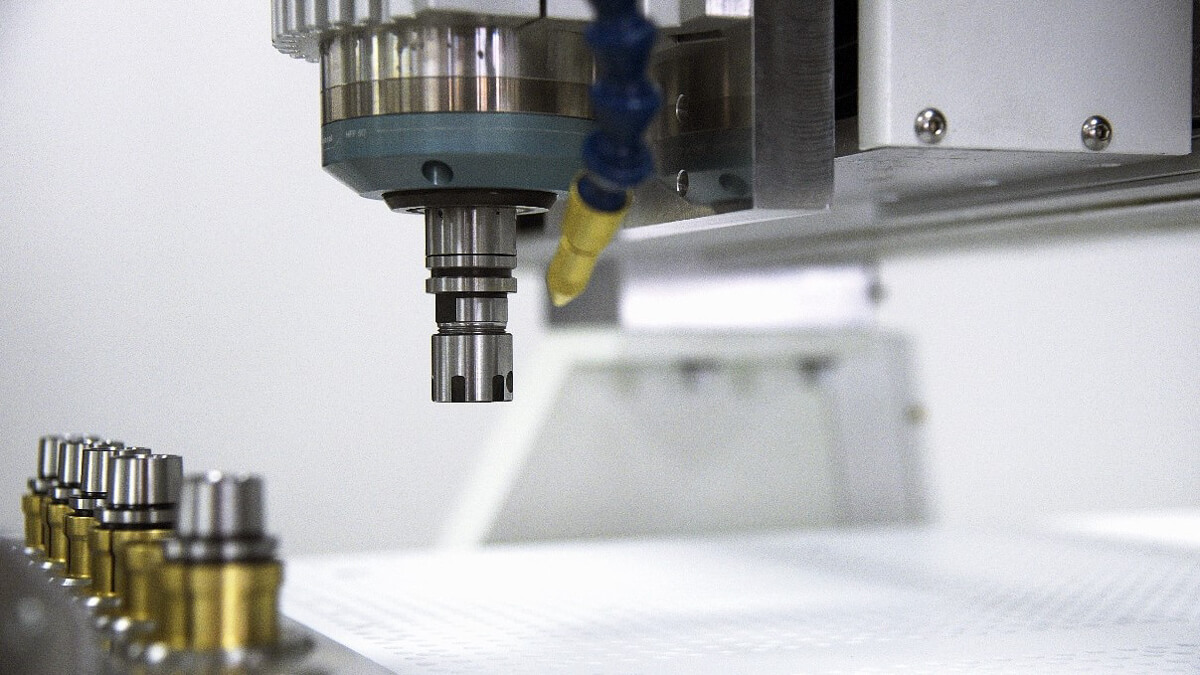

Are you in the market for a new CNC spindle but don’t know where to start? With so many options available, it can be overwhelming to choose the right one for your specific needs. Fear not, as we’ve compiled a guide to help you navigate the world of CNC spindles and make an informed decision.

Whether you’re a seasoned machinist or just getting started in the industry, choosing the right CNC spindle is crucial for achieving optimal performance and accuracy in your machining projects. From power and speed to compatibility and pricing, there are several factors to consider when selecting a spindle that meets your requirements. Let’s delve into the details and simplify the process for you.

- Consider the material you will be cutting and its hardness. Choose a spindle with enough power to handle the material.

- Look at the speed range of the spindle. Make sure it can handle the range of speeds required for your work.

- Check the taper style of the spindle. Make sure it matches the taper style of your machine tool.

- Consider the type of tool holder you will be using. Make sure the spindle has the appropriate tool holder interface.

- Look at the cooling system of the spindle. Choose a cooling system that meets your needs for temperature control and lubrication.

How to Choose a CNC Spindle?

Choosing a CNC spindle can be a daunting task, especially if you are new to the world of CNC machining. A CNC spindle is a critical component of a CNC machine, and it plays a vital role in determining the overall performance of the machine. In this article, we will guide you through the process of choosing the right CNC spindle for your machine.

1. Determine the Type of Cutting You Will Perform

The type of cutting you will perform is the first consideration when choosing a CNC spindle. The spindle should be able to handle the type of cutting you intend to do. There are three types of cutting: roughing, semi-finishing, and finishing. Roughing is the removal of large amounts of material, semi-finishing is the removal of moderate amounts of material, and finishing is the removal of small amounts of material.

The spindle’s speed, power, and torque will determine the type of cutting it can handle. A high-speed spindle is suitable for finishing, while a low-speed spindle is suitable for roughing. If you plan to perform multiple types of cutting, you may need a spindle that can handle all three types.

2. Consider the Material You Will Be Cutting

The material you will be cutting is another critical consideration when choosing a CNC spindle. The spindle should be able to handle the material’s hardness and density. The spindle’s speed and torque will determine how well it can cut through the material.

If you plan to cut through hard materials such as titanium or stainless steel, you will need a spindle with high torque and low speed. If you plan to cut through softer materials such as aluminum or plastic, you will need a spindle with high speed and low torque.

3. Look at the Spindle’s Power and Speed

The spindle’s power and speed are two critical factors to consider when choosing a CNC spindle. The spindle’s power is measured in horsepower (HP), and the speed is measured in revolutions per minute (RPM).

The power and speed of the spindle will determine how quickly it can remove material and how accurately it can cut. A higher horsepower spindle can remove material faster, while a lower horsepower spindle will be more accurate.

4. Check the Spindle’s Torque

The spindle’s torque is the amount of twisting force it can produce. The spindle’s torque is essential for cutting through hard materials and for maintaining accuracy.

A higher torque spindle can handle harder materials and maintain accuracy better than a lower torque spindle. The spindle’s torque is measured in Newton-meters (Nm) or pound-feet (lb-ft).

5. Look at the Spindle’s Cooling System

The spindle’s cooling system is another important consideration when choosing a CNC spindle. The cooling system is responsible for keeping the spindle cool during operation. Overheating can cause the spindle to wear out faster and lead to inaccuracies in cutting.

The cooling system can be air-cooled or water-cooled. Air-cooled spindles are less expensive but can’t handle high-speed cutting. Water-cooled spindles are more expensive but can handle high-speed cutting and provide better accuracy.

6. Consider the Spindle’s Noise Level

The noise level of the spindle is another factor to consider. The noise level can affect the operator’s comfort level and the machine’s overall performance. A noisy spindle can also indicate that the spindle is not in good condition.

A low noise level spindle is more comfortable to work with and can provide better accuracy. The spindle’s noise level is measured in decibels (dB).

7. Look at the Spindle’s Size and Weight

The spindle’s size and weight are also important considerations. The spindle should fit the machine’s size and weight requirements. A spindle that is too heavy or too large can cause the machine to vibrate and affect the accuracy of cutting.

A smaller and lighter spindle is suitable for machines with limited space and weight capacity. A larger and heavier spindle is suitable for machines with larger work areas and weight capacity.

8. Check the Spindle’s Durability

The spindle’s durability is another important consideration when choosing a CNC spindle. The spindle should be able to handle the workload and last for a long time. A durable spindle can also save you money in the long run by reducing maintenance costs.

The spindle’s durability depends on the quality of its construction and the materials used. A spindle made of high-quality materials and constructed well will last longer than a spindle made of cheaper materials and poorly constructed.

9. Consider the Spindle’s Manufacturer

The spindle’s manufacturer is also an important consideration. A reputable manufacturer will provide high-quality spindles that are reliable and durable. A reputable manufacturer will also provide excellent customer support and after-sales service.

A manufacturer with a good reputation in the industry will also provide a warranty for their spindles. The warranty will cover any defects or problems that may arise with the spindle.

10. Look at the Spindle’s Price

The spindle’s price is the final consideration when choosing a CNC spindle. The price should fit within your budget and provide the quality and performance you need. A high-quality spindle will cost more, but it will provide better performance and last longer.

It’s essential to balance the price with the spindle’s performance and durability. A spindle that is too cheap may not provide the performance and durability you need, while a spindle that is too expensive may not fit within your budget.

In conclusion, choosing the right CNC spindle is critical for the overall performance of your machine. Consider the type of cutting you will perform, the material you will be cutting, the spindle’s power and speed, the spindle’s torque, the cooling system, the noise level, the size and weight, the durability, the manufacturer, and the price. With these factors in mind, you can choose the right CNC spindle for your needs.

Frequently Asked Questions

In this section, we will answer some of the most common questions about choosing a CNC spindle. Whether you are a beginner or an experienced machinist, you will find valuable information to help you make an informed decision.

What are the most important factors to consider when choosing a CNC spindle?

There are several factors to consider when choosing a CNC spindle, including power, speed, precision, and noise level. The power of the spindle determines how much material it can remove in a given amount of time. The speed of the spindle is important for achieving the desired surface finish and minimizing tool wear. The precision of the spindle is crucial for achieving high-quality, accurate cuts. Finally, the noise level of the spindle is an important consideration if you are working in a shared space.

Other factors to consider include the type of material you will be cutting, the size of the parts you will be working with, and the type of tooling you will be using. It is also important to consider the cost of the spindle and any additional accessories you may need.

What is the difference between an air-cooled and a water-cooled spindle?

An air-cooled spindle uses a fan to cool the motor and prevent overheating. This type of spindle is typically smaller and less expensive than a water-cooled spindle. However, it may not be as efficient at dissipating heat, which can limit its performance in certain applications.

A water-cooled spindle uses a liquid coolant to dissipate heat and keep the motor cool. This type of spindle is typically larger and more expensive than an air-cooled spindle. However, it is more efficient at dissipating heat, which allows it to operate at higher speeds and with greater precision. It is also quieter than an air-cooled spindle.

What is the difference between a belt-driven and a direct-drive spindle?

A belt-driven spindle uses a belt to transfer power from the motor to the spindle. This type of spindle is typically less expensive than a direct-drive spindle. However, it may not be as precise or as powerful as a direct-drive spindle.

A direct-drive spindle uses a motor that is directly connected to the spindle. This type of spindle is typically more expensive than a belt-driven spindle. However, it is more precise and more powerful, which makes it ideal for high-speed and high-precision applications.

What is the maximum RPM that a CNC spindle can achieve?

The maximum RPM that a CNC spindle can achieve depends on several factors, including the size and design of the spindle, the power of the motor, and the type of bearings used. In general, most CNC spindles can achieve speeds between 5,000 and 24,000 RPM. However, some high-end spindles can achieve speeds up to 60,000 RPM.

It is important to choose a spindle that can achieve the necessary speed for your specific application. If you are working with materials that require high-speed cutting, you will need a spindle that can achieve high RPMs. However, if you are working with harder materials that require slower cutting speeds, a lower RPM spindle may be sufficient.

What is the best way to maintain a CNC spindle?

The best way to maintain a CNC spindle is to follow the manufacturer’s recommended maintenance schedule. This may include regular cleaning, lubrication, and inspection of the spindle bearings. It is also important to use the correct tooling and to avoid overloading the spindle.

If you notice any unusual sounds or vibrations coming from the spindle, it is important to stop the machine and inspect the spindle for damage. Regular maintenance can help extend the life of your spindle and ensure that it operates at peak performance.

In conclusion, choosing the right CNC spindle for your machine is a crucial decision that can significantly impact your work. By considering the factors mentioned above, such as speed, power, and material compatibility, you can make an informed decision that will improve your productivity and overall output quality.

It is also important to remember that investing in a high-quality CNC spindle may cost more initially, but it can save you money and time in the long run by reducing the need for repairs and replacements.

Lastly, don’t hesitate to seek advice from experts or industry professionals, as they can provide invaluable insights and recommendations based on their experience and expertise. With the right research and guidance, you can find the perfect CNC spindle that meets your specific needs and requirements.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com