Table of Contents

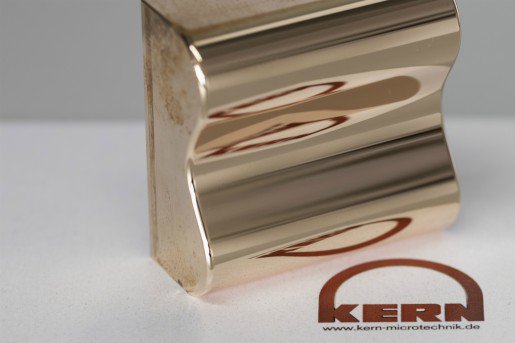

Aluminum is a versatile material with many industrial applications, from aerospace to automotive. But achieving a mirror finish on aluminum can be a tricky task, especially when using CNC turning. However, with the right techniques and tools, it is possible to achieve a smooth and reflective surface that rivals the look of a traditional glass mirror.

In this article, we will explore the step-by-step process to CNC turn mirror finish on aluminum. We will cover everything from selecting the right tools and materials, to optimizing your machine settings and polishing techniques. Whether you’re a seasoned machinist or a beginner, this guide will provide you with the knowledge and skills to achieve a beautiful mirror finish on your aluminum parts.

- Choose the right grade of aluminum for a mirror finish.

- Ensure that the CNC machine is properly calibrated and the cutting tools are sharp.

- Use a high-speed spindle with a diamond or polished tool to achieve a highly reflective finish.

- Make sure that the cutting speed is slow and the feed rate is high to avoid any scratches or marks on the surface.

- Finally, use a polishing compound and buffing wheel to further enhance the shine of the aluminum.

How to CNC Turn Mirror Finish on Aluminum?

CNC turning is an essential process in the manufacturing industry, and achieving a mirror finish on aluminum parts can be a challenging task. However, with the right techniques and tools, it is possible to achieve a flawless mirror finish on your aluminum parts. In this article, we will discuss the steps involved in CNC turning mirror finish on aluminum.

Step 1: Choose the Right Material

The first step in achieving a mirror finish on aluminum is selecting the right material. Aluminum alloys such as 6061 and 7075 are commonly used in CNC turning because of their excellent machinability and high strength-to-weight ratio. However, it is important to note that different aluminum alloys have varying properties that can affect the surface finish.

To achieve a mirror finish, it is recommended to use aluminum with a low copper content, as copper can cause surface defects during machining. Additionally, the aluminum should be annealed to reduce internal stresses and improve machinability.

Step 2: Use the Right Tools

Using the right tools is crucial in achieving a mirror finish on aluminum. High-speed steel (HSS) and carbide tools are commonly used in CNC turning. Carbide tools are preferred for their high wear resistance, while HSS tools are suitable for finishing cuts.

To achieve a mirror finish, it is recommended to use a diamond-tipped tool. Diamond tools are capable of cutting aluminum with high precision and leaving a smooth surface finish. Additionally, diamond tools have a longer lifespan than other cutting tools, reducing the need for frequent tool changes.

Step 3: Implement the Right Machining Parameters

The machining parameters used in CNC turning can have a significant impact on the surface finish of aluminum parts. To achieve a mirror finish, it is recommended to use a low feed rate and high spindle speed. A low feed rate reduces the amount of heat generated during machining, which can cause surface defects, while a high spindle speed ensures a smooth surface finish.

Additionally, it is recommended to use a small depth of cut to reduce the risk of tool chatter and improve surface finish. The cutting speed should also be set to a value that is suitable for the specific aluminum alloy being machined.

Step 4: Use Lubrication

Lubrication is essential in achieving a mirror finish on aluminum. The use of a suitable lubricant reduces the risk of surface defects and improves surface finish. The lubricant should be applied continuously during machining to ensure a smooth surface finish.

It is recommended to use a water-soluble coolant that is free from chlorine and sulfur. Chlorine and sulfur can cause surface defects and affect the overall surface finish.

Step 5: Implement a Finishing Pass

After the roughing passes, it is recommended to implement a finishing pass to achieve a mirror finish on aluminum. The finishing pass should be performed using a diamond-tipped tool and a low feed rate to reduce the risk of surface defects.

Additionally, it is recommended to use a small depth of cut and high spindle speed to ensure a smooth surface finish. The cutting speed should also be set to a value that is suitable for the specific aluminum alloy being machined.

Step 6: Clean the Machined Surface

Once the machining process is complete, it is important to clean the machined surface to remove any debris and contaminants. The use of a suitable cleaning solution and a lint-free cloth is recommended to ensure a clean surface.

Additionally, it is recommended to use a microfiber cloth to remove any remaining debris and improve the overall surface finish. The machined part should be inspected for any surface defects and cleaned again if necessary.

Step 7: Benefits of CNC Turning Mirror Finish on Aluminum

CNC turning mirror finish on aluminum has several benefits, including:

– Improved aesthetic appeal: A mirror finish on aluminum parts enhances their appearance and makes them more visually appealing.

– Increased corrosion resistance: A mirror finish on aluminum parts reduces the risk of corrosion and improves their durability.

– Improved performance: A mirror finish on aluminum parts can improve their performance by reducing friction and wear.

Step 8: Vs Comparison

CNC turning mirror finish on aluminum has several advantages over other finishing techniques, including:

– Superior surface finish: CNC turning mirror finish produces a smoother and more uniform surface finish than other finishing techniques.

– Increased precision: CNC turning can achieve higher levels of precision than other finishing techniques, resulting in a more accurate and consistent surface finish.

– Reduced lead times: CNC turning is a faster and more efficient finishing technique, reducing lead times and improving productivity.

Step 9: Common Surface Defects and How to Avoid Them

During CNC turning, several surface defects can occur that can affect the overall surface finish. Some common surface defects and how to avoid them are:

– Chatter marks: Chatter marks can occur when the tool vibrates during machining. To avoid chatter marks, it is recommended to use a small depth of cut and high spindle speed.

– Built-up edge: Built-up edge occurs when the tool material adheres to the workpiece material. To avoid built-up edge, it is recommended to use a suitable lubricant and ensure the cutting speed is set to an appropriate value.

– Tool marks: Tool marks can occur when the tool is not sharp or has been damaged. To avoid tool marks, it is recommended to use a sharp tool and replace it when necessary.

Step 10: Conclusion

Achieving a mirror finish on aluminum parts is a challenging task, but with the right techniques and tools, it is possible to achieve a flawless surface finish. By following the steps outlined in this article, you can achieve a mirror finish on your aluminum parts and enjoy the benefits of improved aesthetic appeal, increased corrosion resistance, and improved performance.

Freequently Asked Questions

Here are some frequently asked questions about how to CNC turn mirror finish on aluminum:

What is CNC turning?

CNC turning is a manufacturing process in which a cutting tool is used to remove material from a rotating workpiece. This process is controlled by a computer program, which ensures precise and accurate cuts. CNC turning is commonly used in the production of cylindrical parts, such as shafts, bolts, and fittings.

To achieve a mirror finish on aluminum using CNC turning, it is important to use the right cutting tool and cutting parameters. The cutting tool should be sharp and have a high rake angle, which will reduce cutting forces and prevent the material from deforming. The cutting speed, feed rate, and depth of cut should also be optimized for aluminum to ensure a smooth and shiny surface.

What are the benefits of a mirror finish on aluminum?

A mirror finish on aluminum can enhance the appearance and functionality of the part. It provides a smooth and shiny surface that is aesthetically pleasing and easy to clean. A mirror finish also improves the corrosion resistance and durability of the part, as it reduces the surface area for dirt, moisture, and other contaminants to adhere to.

To achieve a mirror finish on aluminum using CNC turning, it is important to use the right cutting tool and cutting parameters. The cutting tool should be sharp and have a high rake angle, which will reduce cutting forces and prevent the material from deforming. The cutting speed, feed rate, and depth of cut should also be optimized for aluminum to ensure a smooth and shiny surface.

What types of aluminum are suitable for mirror finishing?

Most types of aluminum can be mirror finished using CNC turning, but some grades are more suitable than others. High-purity aluminum alloys, such as 6061 and 7075, are commonly used in CNC turning applications due to their excellent machinability and surface finish. These alloys are also resistant to corrosion and have high strength-to-weight ratios.

To achieve a mirror finish on aluminum using CNC turning, it is important to use the right cutting tool and cutting parameters. The cutting tool should be sharp and have a high rake angle, which will reduce cutting forces and prevent the material from deforming. The cutting speed, feed rate, and depth of cut should also be optimized for aluminum to ensure a smooth and shiny surface.

What are some tips for achieving a mirror finish on aluminum using CNC turning?

Here are some tips for achieving a mirror finish on aluminum using CNC turning:

- Use a sharp cutting tool with a high rake angle

- Optimize the cutting speed, feed rate, and depth of cut for aluminum

- Minimize cutting forces to prevent material deformation

- Use a fine-grit polishing compound to remove scratches and surface imperfections

- Apply a protective coating or anodizing treatment to improve durability and corrosion resistance

By following these tips, you can achieve a high-quality mirror finish on aluminum using CNC turning.

What are some common challenges when CNC turning mirror finish on aluminum?

Some common challenges when CNC turning mirror finish on aluminum include:

- Material deformation due to cutting forces

- Surface scratches and imperfections

- Difficulty in achieving a uniform surface finish

- Difficulty in removing fine swarf and particles from the surface

To overcome these challenges, it is important to use the right cutting tool and cutting parameters, as well as a fine-grit polishing compound and a protective coating or anodizing treatment.

In conclusion, achieving a mirror finish on aluminum using CNC turning requires skill, patience, and attention to detail. With the right tools and techniques, it is possible to achieve a flawless finish that will impress even the most discerning of observers.

One important factor to keep in mind is the importance of proper tool selection. Choosing the right tools for the job can make all the difference in achieving a smooth and even finish. Additionally, taking the time to properly prepare the aluminum before beginning the turning process can help to ensure a professional-looking result.

Finally, it is important to remember that CNC turning is a process that requires practice to master. By taking the time to perfect your techniques and continually refining your approach, you can develop the skills necessary to achieve exceptional results. With patience, dedication, and a commitment to excellence, you can take your CNC turning skills to the next level and produce mirror-finish aluminum parts that are sure to impress.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com