Table of Contents

- How to Cut Left Hand Threads on a CNC Lathe?

- Step 1: Selecting the Right Tooling

- Step 2: Setting the Machine Parameters

- Step 3: Starting the Cut

- Step 4: Finishing the Cut

- Step 5: Benefits of Left-Hand Threads

- Step 6: Left-Hand Threads Vs. Right-Hand Threads

- Step 7: Tips for Cutting Left-Hand Threads

- Step 8: Common Mistakes

- Step 9: Conclusion

- Step 10: References

- Frequently Asked Questions

Have you ever wondered how to cut left-hand threads on a CNC lathe? It’s a common question among machinists, and learning how to do it can open up a world of possibilities for your projects.

Left-hand threads are essential for many applications, such as automotive and aerospace industries, where they are needed to prevent loosening due to rotation. In this article, we will explore the step-by-step process of cutting left-hand threads on a CNC lathe and help you master this useful skill. So, let’s dive in and unlock the potential of your CNC lathe.

- Before starting, make sure the CNC lathe is set to the correct spindle speed and feed rate for the material being used.

- Select the appropriate threading tool and insert it into the CNC lathe’s tool holder.

- Next, set the tool’s cutting edge to the correct angle for cutting left-hand threads.

- Adjust the tool’s position and depth of cut to ensure the threads are cut to the correct depth and pitch.

- Finally, run the CNC lathe program and monitor the cutting process to ensure the threads are cut accurately.

How to Cut Left Hand Threads on a CNC Lathe?

Left-hand threads are a valuable feature in many applications, such as threaded fasteners, screws, and bolts. They are used in situations where a clockwise motion would cause the fastener to loosen, and a counterclockwise motion would tighten it. Cutting left-hand threads on a CNC lathe can be tricky, but with the right technique and tools, it can be done easily. In this article, we will discuss the steps involved in cutting left-hand threads on a CNC lathe.

Step 1: Selecting the Right Tooling

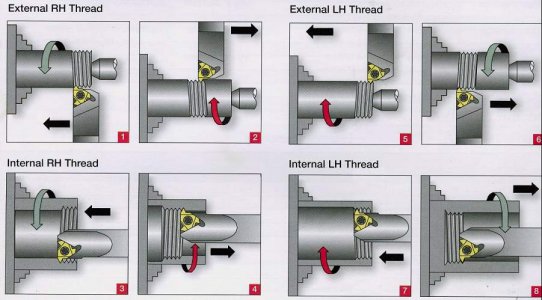

The first step in cutting left-hand threads on a CNC lathe is to select the right tooling. You will need a left-hand turning tool to cut left-hand threads. This tool is designed to cut in the opposite direction of a right-hand turning tool. When selecting the tool, make sure it is the correct size for the thread you want to cut.

Once you have selected the tool, you will need to set the tool height. This is critical to ensure that the tool is cutting at the correct angle. You can use a tool height gauge to set the tool height accurately.

Step 2: Setting the Machine Parameters

The next step is to set the machine parameters. You will need to set the spindle speed, feed rate, and depth of cut. These parameters will vary depending on the material you are cutting and the size of the thread you want to cut. Refer to the manufacturer’s guidelines for recommended speeds and feeds.

When setting the depth of cut, it is essential to take into account the pitch of the thread. The depth of cut should be equal to half the pitch of the thread. For example, if you are cutting a thread with a pitch of 1mm, the depth of cut should be 0.5mm.

Step 3: Starting the Cut

Once you have set the machine parameters, you can start the cut. Begin by approaching the workpiece slowly and making light contact with the tool. Once you have established a good cut, gradually increase the feed rate until you are cutting at the desired rate.

It is essential to monitor the cutting process carefully to ensure that the tool is cutting the thread correctly. If you notice any signs of chatter or vibration, you may need to adjust the machine parameters or the tool position.

Step 4: Finishing the Cut

As you approach the end of the cut, it is essential to slow down the feed rate to ensure a smooth finish. You may also need to reduce the spindle speed to prevent the tool from overheating. Once the cut is complete, carefully remove the workpiece from the lathe.

Step 5: Benefits of Left-Hand Threads

Left-hand threads offer several benefits in certain applications. For example, they are used in situations where a clockwise motion would cause the fastener to loosen, and a counterclockwise motion would tighten it. They are also used in applications where it is necessary to differentiate between right-hand and left-hand fasteners.

Step 6: Left-Hand Threads Vs. Right-Hand Threads

Left-hand threads are the opposite of right-hand threads. The difference between them is the direction in which they tighten. Right-hand threads tighten clockwise, while left-hand threads tighten counterclockwise. The choice between left-hand and right-hand threads depends on the application and the requirements.

Step 7: Tips for Cutting Left-Hand Threads

Cutting left-hand threads on a CNC lathe requires some skill and practice. Here are some tips to help you get started:

- Use the correct tooling and set the tool height accurately.

- Set the machine parameters carefully, taking into account the material and the size of the thread.

- Monitor the cutting process carefully to ensure that the tool is cutting the thread correctly.

- Slow down the feed rate and the spindle speed as you approach the end of the cut.

Step 8: Common Mistakes

Cutting left-hand threads on a CNC lathe can be challenging, and there are some common mistakes to avoid. These include:

- Using the wrong tooling or the wrong size tooling

- Setting the tool height incorrectly

- Setting the machine parameters incorrectly

- Not monitoring the cutting process carefully

- Removing the workpiece from the lathe too quickly

Step 9: Conclusion

Cutting left-hand threads on a CNC lathe requires careful preparation, the right tooling, and the correct machine parameters. By following the steps outlined in this article, you can successfully cut left-hand threads on a CNC lathe and enjoy the benefits they offer in certain applications.

Step 10: References

Here are some references you can consult for more information on cutting left-hand threads on a CNC lathe:

- Haas Automation, Inc. (2021). Cutting Left-Hand Threads on a Lathe. Retrieved from https://www.haascnc.com/service/troubleshooting-and-how-to/how-to/cutting-left-hand-threads-on-a-lathe.html

- Mazak Corporation. (2021). How to Cut Left-Hand Threads on a CNC Lathe. Retrieved from https://www.mazakusa.com/learning-resources/how-to-cut-left-hand-threads-on-a-cnc-lathe/

Frequently Asked Questions

Left-hand threads are used in several applications, including bolts, screws, and nuts. However, cutting these threads on a CNC lathe can be tricky, especially if you are new to the process. Here are some frequently asked questions about how to cut left-hand threads on a CNC lathe.

Q: What is a left-hand thread?

A left-hand thread is a screw thread that is designed to tighten when turned counterclockwise. These threads are used in applications where a right-hand thread would loosen over time due to vibration or torque. Examples of left-hand threaded items include bicycle pedals, gas valves, and turnbuckles.

To cut a left-hand thread on a CNC lathe, you will need to reverse the direction of the cutting tool rotation. This is done by switching the direction of the spindle rotation and adjusting the program accordingly.

Q: How do I set up my CNC lathe to cut left-hand threads?

To set up your CNC lathe for left-hand threading, you will need to make several adjustments to your machine and program. First, you will need to reverse the direction of the spindle rotation. This can be done by changing the wiring in the control cabinet or using a reversing switch. Next, you will need to adjust the program to account for the reversed direction of the cutting tool. Finally, you will need to use a left-hand cutting tool to create the threads.

It is also important to note that left-hand threads require the opposite feed rate and depth of cut as right-hand threads. This means that you will need to adjust these parameters accordingly in your program.

Q: What are some tips for cutting left-hand threads on a CNC lathe?

Cutting left-hand threads on a CNC lathe can be challenging, but there are several tips that can help you achieve success. First, make sure to use a left-hand cutting tool designed for the specific thread size and pitch you need. Next, double-check your program to ensure that it is set up correctly for left-hand threading. Finally, use a slow and steady approach when cutting the threads, as this will help prevent tool breakage and ensure a clean finish.

Additionally, it is a good idea to test your program on a scrap piece of material before cutting the actual part. This will allow you to make any necessary adjustments and ensure that you get the desired results.

Q: What are some common mistakes to avoid when cutting left-hand threads on a CNC lathe?

Cutting left-hand threads on a CNC lathe can be challenging, and there are several common mistakes that you should avoid. First, make sure that you have reversed the direction of the spindle rotation and adjusted the program accordingly. Failure to do so can result in a damaged part or broken tool.

Another mistake to avoid is using a right-hand cutting tool instead of a left-hand cutting tool. Right-hand tools will not work for left-hand threading and can cause damage to your machine or part. Finally, make sure to use the correct feed and speed rates for left-hand threading, as these are different from right-hand threading.

In conclusion, cutting left-hand threads on a CNC lathe is a crucial skill that every machinist should master. With the right tools, techniques, and approach, creating high-quality threads is possible. However, it requires patience, attention to detail, and practice to achieve the desired results.

One of the key takeaways from this guide is that selecting the right tool and setting the correct parameters is essential. Additionally, understanding the importance of the cutting speed, depth of cut, and feed rate is crucial to achieving the correct thread profile. With these factors in mind, you can produce accurate threads with minimal errors.

Lastly, remember that practice makes perfect. It’s essential to put in the effort to hone your skills and learn from your mistakes. Whether you’re a novice or an experienced machinist, there’s always room for improvement. By following the steps outlined in this guide and putting in the time and effort, you can master the art of cutting left-hand threads on a CNC lathe.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com