Table of Contents

If you’re looking to create high-quality parts for CNC machining, there are a few key design principles you need to keep in mind. From selecting the right materials to understanding the importance of accurate measurements, designing for CNC machining requires a certain level of expertise and attention to detail. But with the right approach, you can create parts that are both functional and aesthetically pleasing.

In this guide, we’ll take a closer look at the key factors that go into designing parts for CNC machining. Whether you’re a seasoned pro or just getting started, you’ll find plenty of useful tips and tricks to help you create parts that meet your exact specifications. So if you’re ready to take your CNC machining skills to the next level, read on to learn more!

How to Design Parts for CNC Machining?

If you’re looking to create high-quality parts with CNC machining, it’s important to design your parts with the manufacturing process in mind. CNC machining is a highly precise and efficient manufacturing process, but it requires careful planning and design to achieve the best results. In this article, we’ll take a closer look at how to design parts for CNC machining, including the key considerations and best practices to follow.

1. Understanding CNC Machining

CNC machining is a manufacturing process that uses computer-controlled machines to cut, shape, and form metal parts. The machines are programmed to follow a precise set of instructions, allowing them to create highly accurate and precise parts. To design parts for CNC machining, it’s important to understand how the process works and what its limitations are.

When designing parts for CNC machining, you need to consider the following factors:

– Material selection: The material you choose will impact the machining process, so it’s important to choose a material that is compatible with CNC machining. Common materials for CNC machining include aluminum, brass, steel, and titanium.

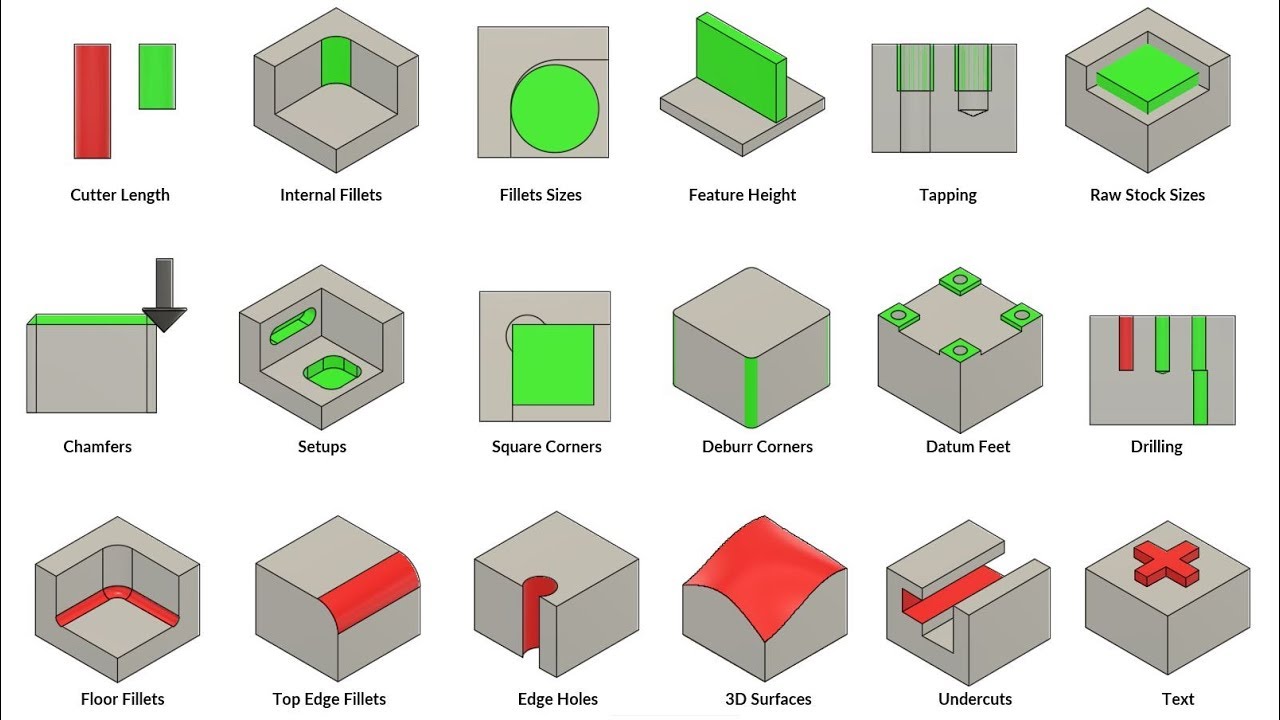

– Part geometry: The geometry of your part will determine how it is machined, so it’s important to design parts with CNC machining in mind. Avoid sharp corners and complex shapes that may be difficult to machine.

– Tolerances: CNC machining can achieve high levels of precision, but it’s important to design parts with the appropriate tolerances to ensure the final product meets your specifications.

2. Designing for CNC Machining

When designing parts for CNC machining, it’s important to follow best practices to ensure your parts are accurately and efficiently machined. Here are some tips to keep in mind:

– Start with a 3D model: A 3D model can help you visualize your part and identify any potential issues before machining begins.

– Minimize material waste: CNC machining can be expensive, so it’s important to design parts that minimize material waste. Consider using nesting software to optimize material usage.

– Use fillets and radii: Sharp corners can be difficult to machine, so it’s best to use fillets and radii instead.

– Avoid undercuts: Undercuts can be difficult to machine, so it’s best to avoid them if possible.

– Consider surface finish: CNC machining can achieve a range of surface finishes, so it’s important to consider the desired finish when designing your part.

3. Benefits of CNC Machining

CNC machining offers a range of benefits, including:

– High precision: CNC machining can achieve high levels of precision, making it ideal for creating complex parts with tight tolerances.

– Efficiency: CNC machining is a highly efficient manufacturing process, allowing for fast turnaround times and low production costs.

– Consistency: CNC machining produces consistent results, ensuring that each part is identical to the next.

– Flexibility: CNC machining can be used to create parts in a range of materials, making it a versatile manufacturing process.

4. CNC Machining vs. Other Manufacturing Processes

CNC machining offers several advantages over other manufacturing processes, such as:

– Injection molding: CNC machining is ideal for creating low-volume parts, whereas injection molding is better suited for high-volume production.

– 3D printing: CNC machining can achieve higher levels of precision than 3D printing, making it ideal for creating complex parts with tight tolerances.

– Sheet metal fabrication: CNC machining can produce parts with more complex geometries than sheet metal fabrication.

5. Common CNC Machining Techniques

CNC machining uses a range of techniques to create parts, including:

– Milling: Milling uses rotary cutters to remove material from a workpiece, creating a specific shape or form.

– Turning: Turning uses a lathe to rotate a workpiece while a cutting tool removes material, creating a cylindrical shape.

– Drilling: Drilling uses a rotating cutting tool to create holes in a workpiece.

– Boring: Boring uses a single-point cutting tool to enlarge an existing hole in a workpiece.

– Tapping: Tapping uses a cutting tool to create threads in a hole.

6. Common CNC Machining Applications

CNC machining is used in a range of industries and applications, including:

– Aerospace: CNC machining is used to create aircraft components, such as engine parts and landing gear.

– Automotive: CNC machining is used to create engine components, suspension parts, and other automotive components.

– Medical: CNC machining is used to create precision medical devices, such as surgical instruments and implants.

– Electronics: CNC machining is used to create electronic components, such as heat sinks and enclosures.

7. Choosing a CNC Machining Service Provider

When choosing a CNC machining service provider, there are several factors to consider, including:

– Experience: Look for a service provider with extensive experience in CNC machining.

– Equipment: Ensure the service provider has modern, well-maintained equipment to ensure high-quality results.

– Quality control: Look for a service provider with rigorous quality control procedures to ensure the final product meets your specifications.

– Turnaround time: Consider the service provider’s turnaround time to ensure your parts are delivered on schedule.

– Pricing: Compare pricing among different service providers to ensure you’re getting a fair price for the quality of work.

8. Conclusion

Designing parts for CNC machining requires careful planning and attention to detail. By following best practices and considering the key factors involved in CNC machining, you can create high-quality parts that meet your specifications and needs. With its high levels of precision, efficiency, and flexibility, CNC machining is an ideal manufacturing process for a wide range of industries and applications.

9. References

Here are some additional resources for learning more about CNC machining:

– “CNC Machining: The Complete Engineering Guide” by Hubs

– “CNC Machining Handbook: Building, Programming, and Implementation” by Alan Overby

– “CNC Machining Technology: Volume I Design, Development and CIM Strategies” by Graham T. Smith

10. Glossary of Terms

– CNC machining: Computer numerical control machining, a manufacturing process that uses computer-controlled machines to create precise parts.

– Tolerance: The allowable deviation from a specified dimension or measurement.

– Nesting software: Software that optimizes material usage by arranging parts on a sheet of material to minimize waste.

– Fillet: A rounding of an interior or exterior corner.

– Radii: Plural of radius, the distance from the center of a circle to its perimeter.

Frequently Asked Questions

Here are some commonly asked questions about designing parts for CNC machining.

What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to create complex and precise parts. The process involves cutting away material from a raw piece of material using various cutting tools. CNC machining is widely used in industries such as aerospace, automotive, medical, and electronics.

The advantage of CNC machining is that it can produce parts with high accuracy and consistency, making it ideal for producing large quantities of parts that require tight tolerances. Furthermore, CNC machining is highly automated, reducing the need for manual labor and increasing productivity.

What are the key considerations when designing parts for CNC machining?

When designing parts for CNC machining, there are several factors to consider. First, it’s important to choose the right material for the part, as different materials have different machining properties. Second, the part should be designed with manufacturability in mind, meaning that it should be easy to machine and minimize waste material. Third, the part should be designed with the correct tolerances to ensure that it fits and functions properly. Finally, the part should be designed for the specific machine that will be used to manufacture it, taking into account the machine’s cutting tools and capabilities.

By considering these factors, designers can ensure that their parts are optimized for CNC machining, resulting in high-quality, functional parts that can be manufactured efficiently and cost-effectively.

What are some common mistakes to avoid when designing parts for CNC machining?

There are several common mistakes that designers should avoid when designing parts for CNC machining. First, they should avoid designing parts with sharp corners or edges, as these can be difficult to machine and may result in tool breakage. Second, they should avoid designing parts with thin walls or features, as these can be fragile and may break during machining. Third, they should avoid designing parts with undercuts or overhangs that cannot be reached by the cutting tool. Finally, they should avoid designing parts with unnecessary complexity, as this can increase manufacturing time and cost.

By avoiding these mistakes, designers can ensure that their parts are easy to machine and can be manufactured efficiently and cost-effectively.

What are some tips for optimizing parts for CNC machining?

There are several tips for optimizing parts for CNC machining. First, designers should consider using standard tool sizes and avoiding custom tools, as this can reduce manufacturing time and cost. Second, they should design parts with a uniform wall thickness, as this can reduce the risk of deformation during machining. Third, they should consider using fillets or radii instead of sharp corners, as this can reduce the risk of tool breakage. Finally, they should minimize the number of setups required to machine the part, as this can reduce manufacturing time and cost.

By following these tips, designers can optimize their parts for CNC machining, resulting in high-quality, functional parts that can be manufactured efficiently and cost-effectively.

What are some common materials used in CNC machining?

There are several common materials used in CNC machining, including metals such as aluminum, steel, titanium, and brass, as well as plastics such as ABS, polycarbonate, and nylon. Each material has its own unique properties and machining characteristics, and designers should choose the material that best suits the requirements of their part. For example, aluminum is lightweight and corrosion-resistant, making it ideal for aerospace and automotive applications, while steel is strong and durable, making it ideal for structural components.

By choosing the right material for their part, designers can ensure that it can be machined efficiently and cost-effectively, resulting in high-quality, functional parts.

In conclusion, designing parts for CNC machining requires a thorough understanding of the process and the materials being used. By taking into consideration the factors that affect the machining process, such as the cutting speed, tool selection, and material properties, you can create designs that are both functional and efficient.

One key aspect of designing parts for CNC machining is to simplify the design as much as possible. This means reducing the number of features, avoiding sharp corners, and using standard tool sizes whenever possible. By doing so, you can reduce the machining time and cost while ensuring the quality of the final product.

Finally, it’s important to work closely with your CNC machining service provider to ensure that your designs are optimized for their equipment and processes. By collaborating with them early on in the design process, you can avoid costly mistakes and ensure that your parts are manufactured to the highest standards. With these tips in mind, you can create designs that are optimized for CNC machining and achieve the best possible results.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com